1&3"5*/(/4536$5*0/4

-13-

Hold the tool with both hands

while starting the tool, since

torque from the motor can cause the tool to twist.

Start the tool before applying to work and let

the tool come to full speed before contacting

the workpiece. Lift the tool from the work

before releasing the switch. DO NOT turn the

switch “ON” and “OFF” while the tool is under

load; this will greatly decrease the switch life.

The tool is switched “ON” by the switch

button located at the side of the motor

housing. The switch can be locked in the

“ON” position, a convenience for long

grinding operations.

TO TURN THE TOOL “ON” without locking it,

slide the switch button forward by applying

pressure ONLY at the REAR portion of the

button. When pressure is released the switch

button will snap to “OFF” position (Fig. 8).

TO LOCK THE SWITCH “ON”, slide the

switch button forward and press “IN” the

FRONT portion.

TO UNLOCK THE SWITCH, simply press

and release the REAR portion of the button.

Switch is spring loaded and will snap back

automatically.

!

WARNING

Before using a grinding wheel,

be certain that its maximum

safe operating speed is not exceeded by the

nameplate speed of the grinder. Do not exceed

the recom mended wheel diameter.

Grinding wheels should be carefully selected in

order to use the grinder most efficiently. Wheels

vary in type of abrasive, bond, hardness, grit

size and structure. The correct type of wheel to

use is determined by the job. Use disc grinding

wheels for fast grinding of structural steel,

heavy weld beads, steel casting, stainless steel

and other ferrous metals.

Efficient grinding is achieved by controlling the

pressure and keep ing the angle between wheel

and workpiece at 10° to 15°. If the wheel is flat,

the tool is difficult to control. If the angle is too

steep, the pressure is concentrated on a small

area causing burning to the work surface.

!

WARNING

SWITCH

BUTTON

FIG. 8

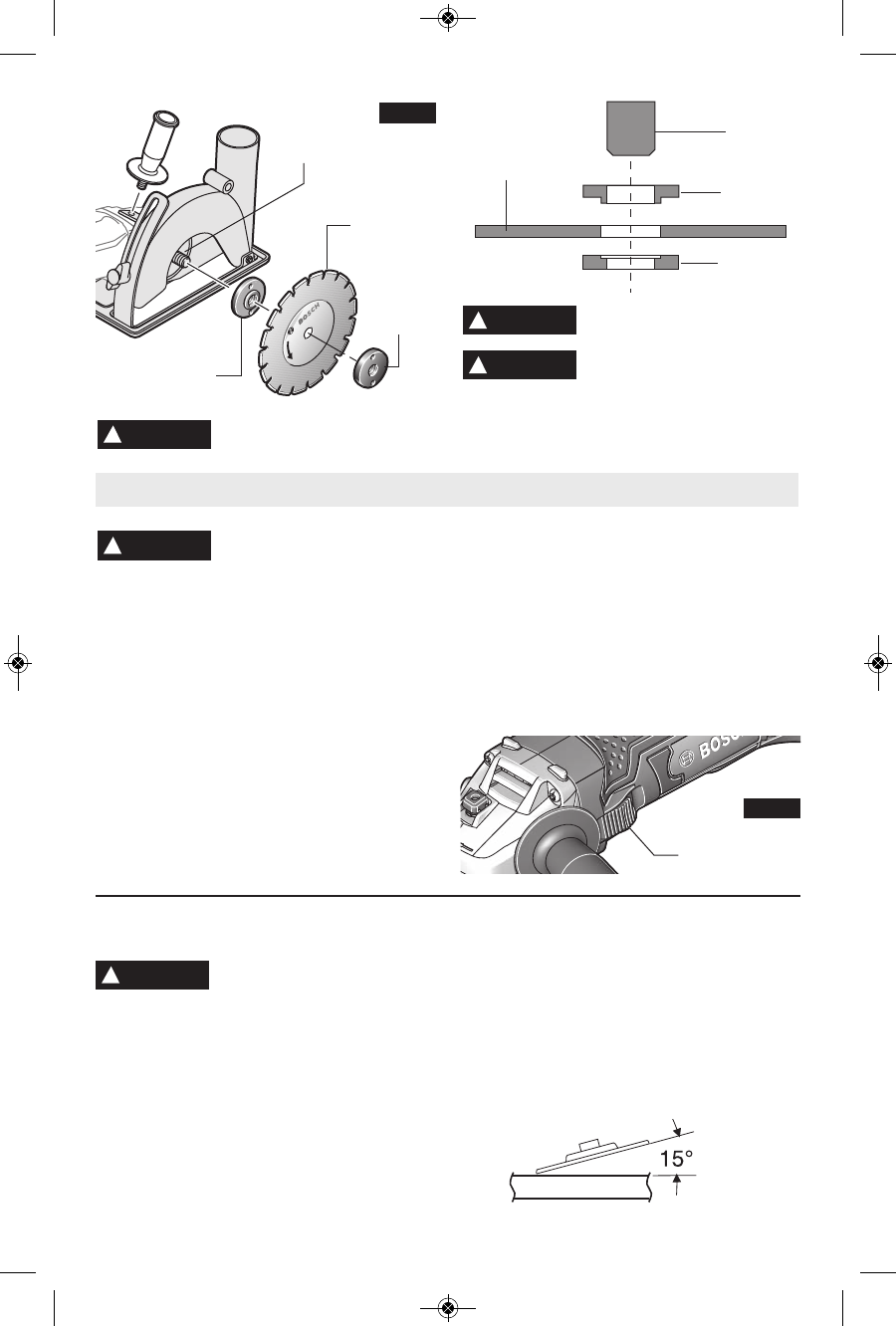

Use only lock nut and flange

with equal diameters.

Do not use water or other

cooling fluid with this tool for

cutting.

!

WARNING

!

WARNING

FIG. 7

SPINDLE

LOCK

NUT

BACKING

FLANGE

DRY

DIAMOND

WHEEL

LOCK NUT

BACKING

FLANGE

SPINDLE

DRY

DIAMOND

WHEEL

3*/%*/(1&3"5*0/4

Do not use dust extraction guards with metal. Use dust extraction guard only

with masonry materials.

!

WARNING

BM 2610034439 04-14_CAG180 4/1/14 7:26 AM Page 13