6

Changing the Fan Wheel Speed by Changing Pulleys

The horsepower rating of the belt is primarily di ctated by

the pitch diameter of the smaller pulley in the drive

system (typically the motor pulley in these units). Do not

install a replacement motor pulley with a smaller pitch

diameter than provided on the original factory pulley.

Change fan wheel speed by changing the fan pulley

(larger pitch diameter to reduce wheel speed, smaller

pitch diameter to increase wheel speed) or select a new

system (both pulleys and matching belt(s).)

Before changing pulleys to increase fan wheel speed,

check the fan performance at the target speed and airflow

rate to determine new motor loading (bhp). Use the fan

performance tables or use the Packaged Rooftop Builder

software program. Confirm that the motor in this unit is

capa ble of operating at the new operating condition. Fan

shaft loading increases dramatically as wheel speed is

increased.

To reduce vibration, replace the motor’s adjustable pitch

pulley with a fixed pitch pulley (after the final airflow

bala nce adjustment). This will reduce the amount of

vibration generated by the motor/belt--drive system.

COOLING

UNIT OPERATION AND SAFETY HAZARD

Failure to follow t his warning could cause personal

injury, death and/or equipment damage.

This system uses PuronR refrigerant which has higher

pressures than R--22 and other refrigerants. No other

refrigerant may be used in this system. Gauge set,

hoses, and recovery system must be designe d to

handle Puron refrigerant. If unsure about equipment,

consult the equipment manufacturer.

!

WARNING

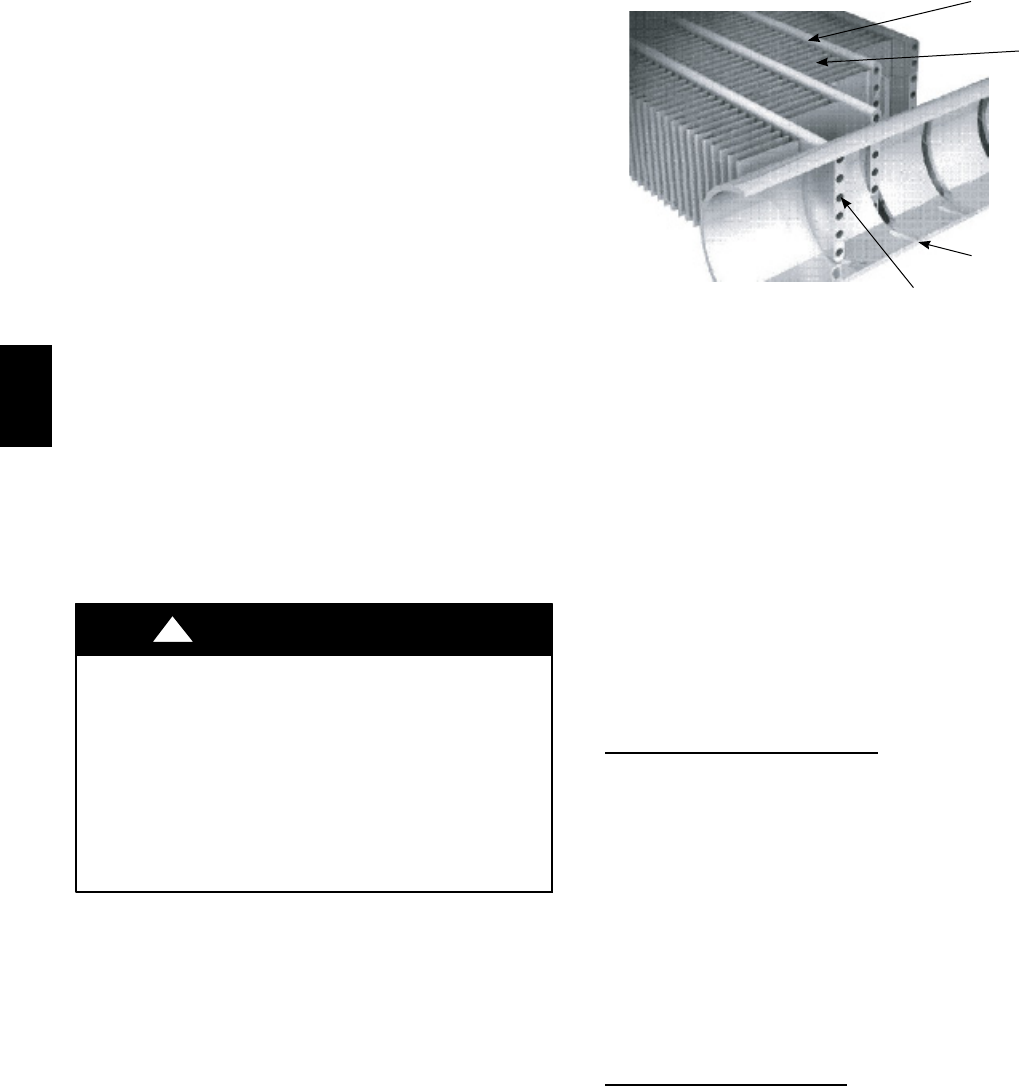

Condenser Coil

The condenser coil is new NOVATION Heat Exchanger

Technology. This is an all--aluminum construction with

louvere d fins over single--depth crosstubes. The

crosstubes have multiple small passages t hrough which

the refrigerant passes from header to header on each end.

Tubes and fins are both aluminum construction.

Connect ion tube joints are copper. The coil may be

one--row or two--row. Two-- row coils are spaced apart to

assist in cleaning. (See Fig. 8.)

TUBES

FINS

MANIFOLD

MICROCHANNELS

C07273

Fig. 8 -- NOVATION Heat Exchanger Coils

Evaporator Coil

The evaporator coil is traditional round--tube, plate--fin

tec hnology. Tube and fin construction is of various

optional materials and c oatings (see Model Number

Format). Coils are multiple -- row.

Coil Maintenance and Cleaning Recommendation

Routine cleaning of coil surfaces is essential to maintain

proper operation of the unit. Elimination of contamination

and removal of harmful residues will greatly increase the

life of the coil and extend the life of the unit. The

following maintenance and cleaning procedures are

recommended as part of the routine maintenance activities

to extend the life of the coil.

Remove Surface Loaded

Fibers

Surface loaded fibers or dirt should be removed with a

vacuum cleaner. If a vacuum cleaner is not available, a

soft non--metallic bristle brush may be used. In either

case, the tool should be applied in the direction of the fins.

Coil surfaces can be easily damaged (fin edges can be

easily bent over and damage to the coating of a protected

coil) if the tool is applied across the fins.

NOTE: Use of a water stream, such as a garden hose,

against a surface loaded coil will drive the fibers and dirt

into the coil. This will make cleaning efforts more

difficult. Surface loaded fibers must be completely

removed prior to using low velocity clean water rinse.

Periodic Clean Water

Rinse

A periodic clean water rinse is very beneficial for coils

that are applied in coastal or industrial environments.

However, it is very important that the water rinse is made

with very low velocity water stream to avoid damaging

the fin edges. Monthly cleaning as described below is

recommended.

580J