3

AT122601, AT125102, AT121002, and AT121102

www.chpower.com

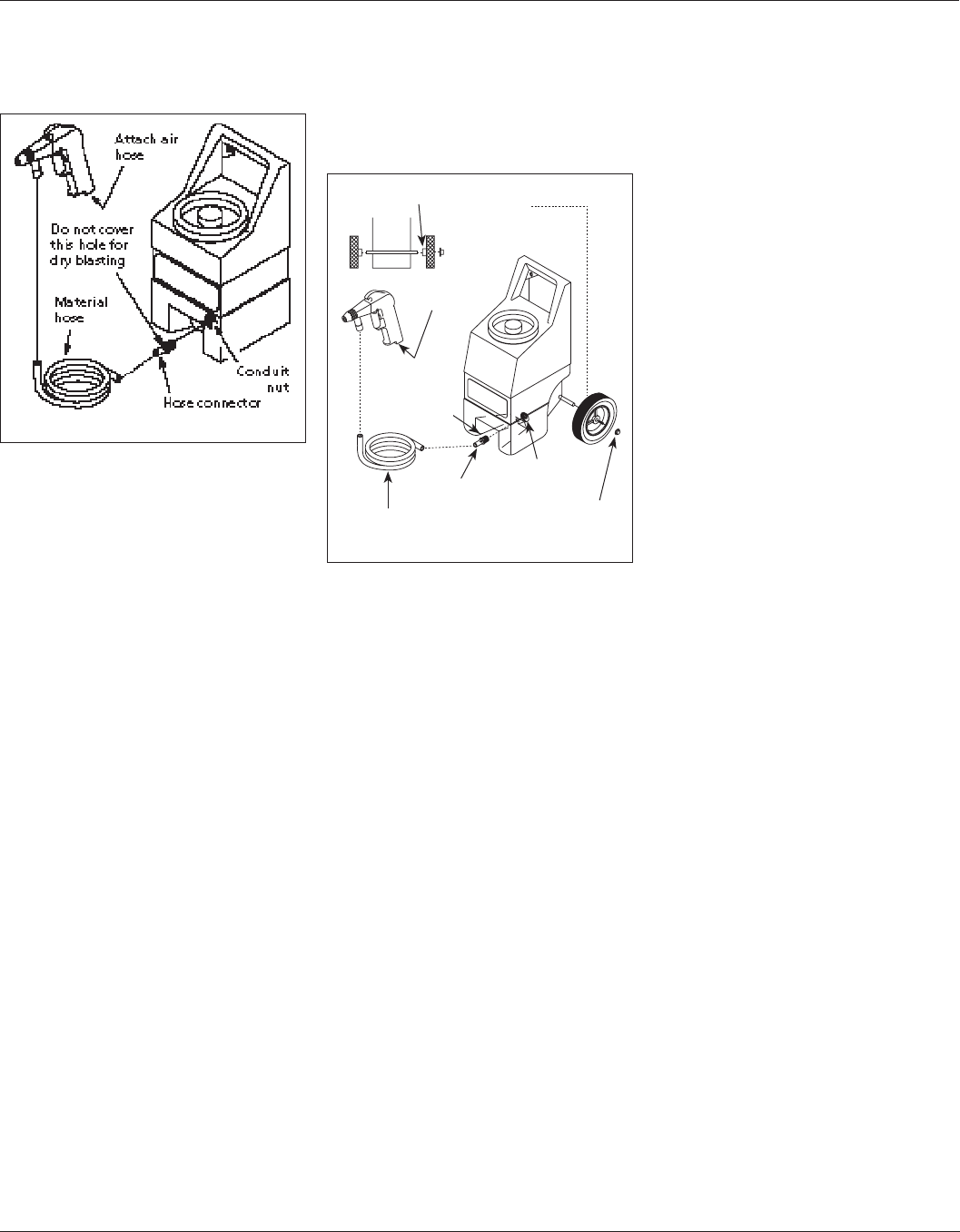

Assembly (Continued)

Figure 6). Never use hose clamps to

secure the hose.

NOTE: Do not cover the hole in the

hose connector for dry blasting. For

spraying liquids, slip the material hose

fully on to the hose connector covering

the hole.

3. Attach the air compressor hose

to the air inlet (1/4 inch NPT(F))

at the bottom of the gun handle.

An optional quick coupler and

connector can be used to attach the

hose to the gun.

ASSEMBLY FOR MODEL AT121102

1. Slide the wheel onto the axle. (See

Figure 7). Lightly hammer on the

wheel cap to secure, making sure

the protruding hub on the wheel is

facing the hopper. Repeat for the

opposite side.

2. Attach the hose connector to the

hopper using the supplied conduit

nut.

3. Attach the material hose to the hose

connector. Attach the opposite end

of the material hose to the gun (See

Figure 7). Never use hose clamps to

secure the hose.

NOTE: Do not cover the hole in the

hose connector for dry blasting. For

spraying liquids, slip the material hose

fully on to the hose connector covering

the hole.

4. Attach the air compressor hose

to the air inlet (1/4 inch NPT(F))

at the bottom of the gun handle.

An optional quick coupler and

connector can be used to attach the

hose to the gun.

Operation

1. Locate the compressor as far away

as possible from the sandblasting

area to minimize the dust in the

compressor intake.

2. The air supply must be clean and

free of moisture and oil.

3. Use a compressor that can supply

enough air (See Specifications). A

compressor too small will cause air

pressure to drop and the sandblaster

will not operate satisfactorily.

4. Always trial test the sandblaster to

make sure the job is done without

damage by testing on a hidden

surface.

5. Always filter (screen) the abrasive

material to remove any caked

material and debris to prevent

clogging.

6. Do not try to spray thick liquids or

large grain size abrasives.

7. Use the lowest effective pressure on

soft surfaces to prevent pitting the

surface.

8. Liquids, such as soap and water, can

be sprayed for cleaning purposes on

automobiles, lawn chairs, etc.

9. Fill the hopper with abrasive to

about 3/4 full.

10. With air hose and material hose

connected, and wearing proper

safety equipment, aim sandblast gun

at surface and pull trigger.

11. Whenever the nozzle is removed

and cleaned or replaced, use a brush

to clean the threads and replace the

o-ring.

Technical Service

For information regarding the

operation or repair of this product,

please call 1-800-543-6400.

Figure 6 - Model AT121002

Figure 7 - Model AT121102

Protruding Hub

Attach Air

Hose

Material Hose

Hose

Connector

Conduit

Nut

Wheel Cap

Do not

cover this

hole when

dry blasting