6-Sp

Manual de Instrucciones

Modelo CHN201

Clavos

Estos clavos para acabado de Campbell Hausfeld los puede comprar en su tienda más cercana. Si necesita ayuda para encon-

trar un artículo, comuníquese al 1-800-543-6400. Los clavos de Campbell Hausfeld cumplen o exceden el estándar ASTM F1667

Calibre Clavos por Clavos por

Modelo # Longitud

del cuerpo

Acabado Cabeza Unión

línea Caja

FB003060 3,18cm (1

1

⁄

4”) 16 Galvanizado De puntilla Adhesivo 50 2500

FB004060 3,81cm (1

1

⁄

2”) 16 Galvanizado De puntilla Adhesivo 50 2500

FB004560 4,45cm (1

3

⁄

4”) 16 Galvanizado De puntilla Adhesivo 50 2500

FB005060 5,08cm (2”) 16 Galvanizado De puntilla Adhesivo 50 2500

FB006560 6,35 cm (2-1/2”) 16 Galvanizado De puntilla Adhesivo 50 2500

FB160025 1" 16 Galvanizado De puntilla Adhesivo 50 1000

FB160040 1-1/2” 16 Galvanizado De puntilla Adhesivo 50 1000

FB160050 2" 16 Galvanizado De puntilla Adhesivo 50 1000

FB160065 2-1/2” 16 Galvanizado De puntilla Adhesivo 50 1000

Información de intercambio

Los clavos usados con la clavadora para acabado CHN201 de Campbell Hausfeld también se pueden usar con las clavadoras

Hitachi NT65A, Paslode 3250-F16, IM250F, Duo Fast LFN-764, Sears 18321, Porter Cable FN200 y FN250.

Cómo usar la

Clavadora (Continuación)

8. Cierre el pestillo

empujándolo hacia

adentro hasta que

ajuste en su posición.

Servicio Técnico

Si desea hacer alguna pregunta refer-

ente a la reparación u operación de las

clavadoras, o para solicitar copias adi-

cionales de este manual, sírvase llamar

a nuestro número especial, 1-800-543-

6400.

Clavos y Refacciones

Use solamente clavos Campbell

Hausfeld originales calibre 16 (o su

equivalente) - (vea la información sobre

intercambio de clavos). El desempeño

!

ADVERTENCIA

de las herramientas, la seguridad y la

duración pueden disminuir si no se

utilizan los clavos adecuados. Cuando

ordene partes de repuesto o clavos,

especifique el número de la parte.

Para reparar la clavadora

La herramienta deberá ser reparada

únicamente por personal calificado, y

deberán usar piezas de repuesto y

accesorios originales Campbell

Hausfeld, o piezas y accesorios que

funcionen de manera equivalente.

Para colocarle los sellos

Cada vez que repare una clavadora

deberá limpiarle y lubricarle las partes

internas. Le recomendamos que use

Parker O-lube o un lubricante equiva-

lente en todos los anillos en O. A cada

anillo en O se le debe dar un baño de

lubricante para anillos antes de insta-

larlos. Igualmente, deberá ponerle un

poco de aceite a todas las piezas que se

mueven y muñones. Finalmente,

después de haberla ensamblado y antes

de probar la herramienta deberá pon-

erle unas cuantas gotas de aceite sin

detergente 30W u otro aceite similar,

en las líneas de aire.

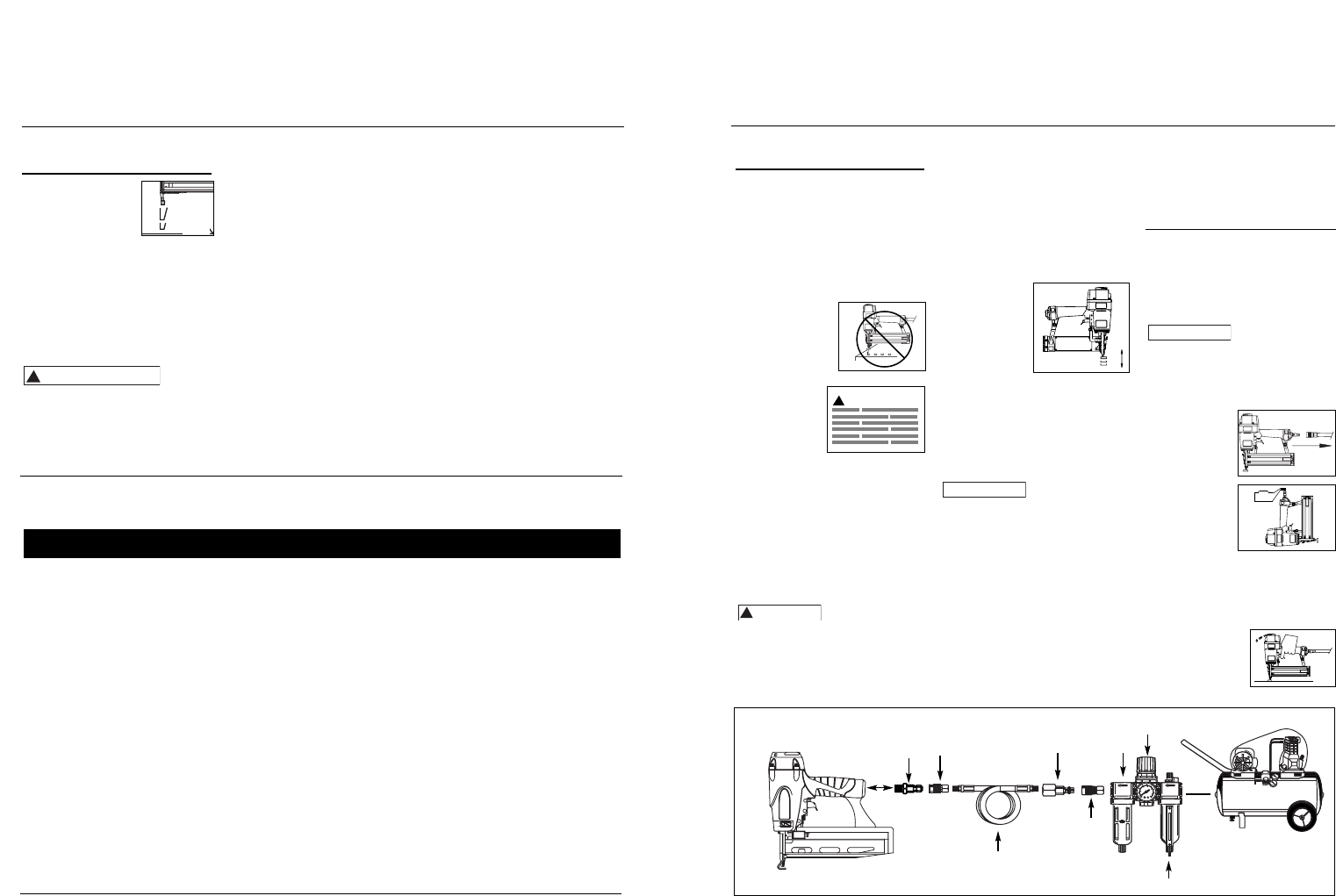

Recommended Hookup

Quick

Plug

Quick

Coupler

Air

Hose

Quick Plug

(Optional)

Quick

Coupler

(Optional)

Oiler

Regulator

Filter

3

General Safety

Information (Continued)

● Always assume the nailer contains

nails. Respect the tool as a working

implement; no horseplay. Always

keep others at a safe distance from

the work area in case of accidental

discharge of nails. Do not point the

tool toward yourself or anyone

whether it contains fasteners or not.

Accidental triggering of the nailer

could result in death or serious per-

sonal injury.

● Do not drive a

nail on top of

other nails. The

nail could glance

and cause death

or a serious punc-

ture wound.

● Do not operate

or allow anyone

else to operate

the nailer if any

warnings or

warning labels

are not legible. Warnings or warning

labels are located on the nailer maga-

zine and body.

● Do not drop or throw the tool.

Dropping or throwing the tool can

result in damage that will make the

tool unusable or unsafe. If the tool

has been dropped or thrown, exam-

ine the tool closely for bent, cracked

or broken parts and air leaks. STOP

and repair before using or serious

injury could occur.

Caution indicates

a potentially haz-

ardous situation which, if not avoided,

MAY result in minor or moderate

injury.

● Do not make any modifications to the

tool without first obtaining written

!

CAUTION

Standard B19.3-1991; Safety

Standard for Compressors for

Process Industries. Contact your air

compressor manufacturer for

information.

Operating The Nailer

LUBRICATION

This nailer requires lubrication before

using the nailer for the first time and

before each use. If an inline oiler is

used, manual lubrication through the

air inlet is not required on a daily basis.

The work surface

can become dam-

aged by excessive lubrication. Proper

lubrication is the owner’s responsibili-

ty. Failure to lubricate the nailer prop-

erly will dramatically shorten the life of

the nailer and void your warranty.

1. Disconnect the

air supply from

the nailer to

add lubricant.

2. Turn the nailer

so the air inlet

is facing up.

Place 4-5 drops

of 30 W non-

detergent oil into air inlet. Do not

use detergent oils, oil additives, or

air tool oils. Air tool oils contain sol-

vents which will damage the nailer's

internal components.

3. After adding oil,

run nailer briefly.

Wipe off any

excess oil from

the cap exhaust.

NOTICE

approval from Campbell Hausfeld. Do

not use the nailer if any shields or

guards are removed or altered. Do

not use the nailer as a hammer.

Personal injury or tool

damage may occur.

● Avoid long extended periods of

work with the nailer. Stop using the

nailer if you feel pain in hands or

arms.

● Always check that the Work Contact

Element (WCE)

is operating

properly. A nail

could acciden-

tally be driven

if the WCE is

not working

properly.

Personal injury

may occur (See "Checking the Work

Contact Element" Section).

● Disconnect air supply and release

tension from the pusher before

attempting to clear jams because

fasteners can be ejected from the

front of the nailer. Personal injury

may occur.

Notice indicates

important infor-

mation, that if not followed, MAY

cause damage to equipment.

● Avoid using the nailer when the

magazine is empty. Accelerated

wear on the nailer may occur.

● Clean and check all air supply hoses

and fittings before connecting the

nailer to an air supply. Replace any

damaged or worn hoses or fittings.

Tool performance or durability may

be reduced.

● Air compressors providing air to the

nailer should follow the require-

ments established by the American

National Standards Institute

NOTICE

Model CHN201

Operating Instructions

OIL

www.chpower.com

O I L

!

WARNING

movemiento