2

Operating Instructions

www.chpower.com

General Safety Information

(Continued)

17. When spraying or cleaning with

solvents or toxic chemicals, follow

the instructions provided by the

chemical manufacturer.

Assembly

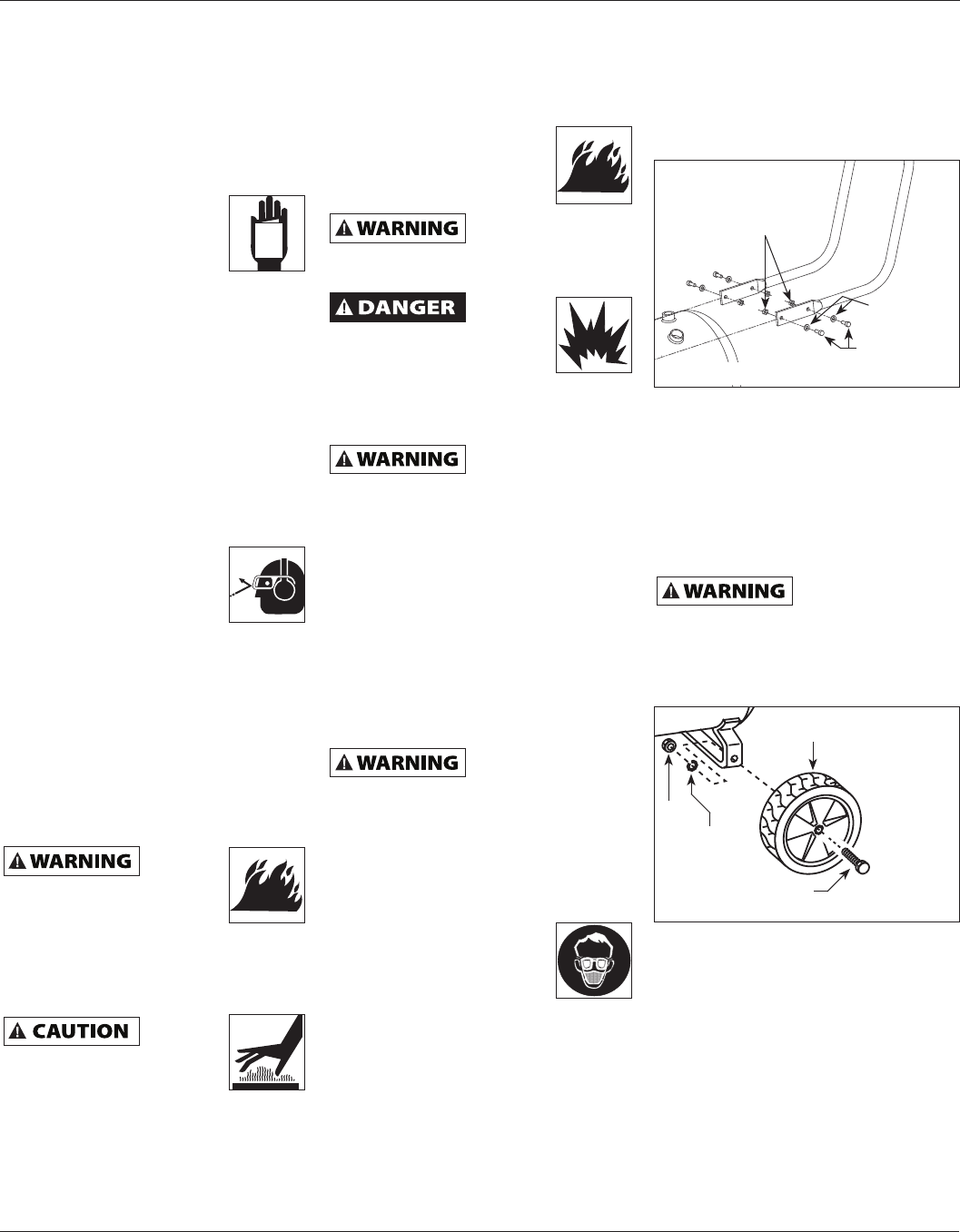

HANDLE ASSEMBLY (Figure 1)

Screws

Washers

Lock Nuts

Figure 1 - Handle Assembly

1. Place ends of handle around tank,

behind the mounting plate. Align

holes in handle to holes in mounting

plate.

2. Assemble four (4) screws and

washers (from parts package)

through holes in mounting plate

and handle. Secure with lock nuts.

Never use the

handle to lift the

unit completely off the ground. Only

use the handle to lift one end so the

wheels may be used to move the unit.

WHEEL ASSEMBLY (Figure 2)

Wheel

Nuts

Lock washer

Screws

Figure 2 - Wheel Assembly

Wheel assembly kit includes:

- 2 wheels*

- 2 axle bolts*

- 2 lock washers*

- 2 nuts*

The items marked with an asterisk (*)

were shipped loose with the unit.

1. Wheel has an offset hub. With offset

hub facing axle iron, assemble axle

bolt through holes in wheel and axle

iron.

Since the air compressor and other

components (filters, lubricators, hoses,

etc.) used, make up a high pressure

pumping system, the following safety

precautions must be observed at all

times:

1. Read all manuals included

with this product carefully.

Be thoroughly familiar

with the controls and the

proper use of the equipment.

2. Follow all local electrical and

safety codes as well as in the US,

National Electrical Code (NEC) and

Occupational Safety and Health Act

(OSHA).

3. Only persons well acquainted with

these rules of safe operation should

be allowed to use the compressor.

4. Keep visitors away and NEVER allow

children in the work area.

5. Wear safety glasses and

use hearing protection

when operating the pump

or unit.

6. Do not stand on or use the pump or

unit as a handhold.

7. Before each use, inspect compressed

air system and electrical components

for signs of damage, deterioration,

weakness or leakage. Repair or

replace defective items before using.

8. Check all fasteners at frequent

intervals for proper tightness.

Motors,

electrical

equipment and controls can

cause electrical arcs that will

ignite a flammable gas or

vapor. Never operate or repair the unit

near a flammable gas or vapor. Never

store flammable liquids or gases in the

vicinity of the compressor.

Com-

pressor

parts may be hot even if the

unit is stopped.

9. Keep fingers away from

a running compressor; fast moving

and hot parts will cause injury and/

or burns.

10. If the equipment should start

to abnormally vibrate, STOP

the engine/motor and check

immediately for the cause. Vibration

is generally a warning of trouble.

11. To reduce fire hazard,

keep engine/motor

exterior free of oil,

solvent, or grease.

Never remove or

attempt to adjust

safety valve. Keep safety valve free

from paint and other accumulations.

Never

attempt

to repair or modify a tank!

Welding, drilling or any other

modification will weaken the

tank resulting in damage from rupture

or explosion. Always replace worn or

damaged tanks.

Drain liquid from

tank daily.

12. Tanks rust from moisture build-up,

which weakens the tank. Make

sure to drain tank daily and inspect

periodically for unsafe conditions

such as rust formation and corrosion.

13. Fast moving air will stir up dust

and debris which may be harmful.

Release air slowly when draining

moisture or depressurizing the

compressor system.

SPRAYING PRECAUTIONS

Do not spray

flammable

materials in vicinity of open flame or

near ignition sources including the

compressor unit.

14. Do not smoke when spraying paint,

insecticides, or other flammable

substances.

15. Use a face mask/

respirator when spraying

and spray in a well

ventilated area to prevent

health and fire hazards.

16. Do not direct paint or other sprayed

material at the compressor. Locate

compressor as far away from

the spraying area as possible to

minimize overspray accumulation on

the compressor.

MANUAL