23 Sp

Guía de diagnóstico de averías (Continuación)

Problema Posible(s) Causa(s) Acción a tomar

1. Conexiones flojas (conexiones,

tuberías, etc.)

2. La llave de drenaje está floja

3. Hay una fuga en la válvula de

chequeo

1. El filtro de entrada está obstruído

2. Hay fugas de aire en las tuberías (del

compresor o del sistema de conexión)

3. Las válvulas de entrada están

dañadas

4. El anillo del pistón está dañado

5. El cilindro o anillo del pistón está

desgastado o rayado

1. Exceso de agua en el tanque

2. Humedad alta

1. El presostato está dañado

2. Consumo excesivo de aire

1. Condensación excesiva en el tanque

2. Hay fugas de aire en las tuberías (del

compresor o del sistema de conexión)

3. Fuga en la válvula de chequeo del

tanque

La válvula de chequeo está atascada y

no se puede cerrar

1. Chequée todas las conexiones con agua enjabonada y

apriételas

2. Apriétela

3. Desmantele la válvula de chequeo, límpiela o

reemplácela

Antes de desmantelar

la válvula de

chequeo purgue el aire del tanque

1. Límpielo o reemplácelo

2. Reemplace las tuberías que tengan fugas o apriételas

según sea necessario

3. Un técnico especializado debe reparar el compresor

4. Reemplácelo

5. Reemplácelo

1. Drene el tanque

2. Mueva el compresor a una área menos húmeda; use

un filtro de aire incorporado a la línea

1. Reemplace el presostato

2. Disminuya el consumo de aire; el compresor es muy

pequeño para suministrar el aire requerido

1. Drénelo con más frecuencia

2. Reemplace las tuberías que tengan fugas o apriételas

según sea necessario

3. Reemplácela o repárela según sea necesario

Antes de desmantelar

la válvula de

chequeo purgue el aire del tanque

Desconecte y reemplace la válvula de chequeo

Antes de desmantelar

la válvula de

chequeo purgue el aire del tanque

!

PELIGRO

!

PELIGRO

!

PELIGRO

La presión del tanque

baja cuando el

compresor se apaga

La salida de aire es

inferior a la normal/la

presión de salida es baja

Exceseso de humedad

en el aire expulsado

El compresor funciona

continuamente

El compresor se

enciende y se apaga

automáticamente con

mucha frecueneia

Hay una fuga de aire en

el sistema de desfogue

del presostato

Serie WL

2

Oilless Compressors

3.Only persons well acquainted with

these rules of safe operation should

be allowed to use the compressor.

4.Keep visitors away and NEVER allow

children in the work area.

5.Wear safety glasses and use hearing

protection when operating the

pump or unit.

6.Do not stand on or use the pump or

unit as a handhold.

7.

Before each use, inspect compressed

air system and electrical components

for signs of damage, deterioration,

weakness or leakage. Repair or

replace defective items before using.

8. Check all fasteners at frequent

intervals for proper tightness.

Motors, electrical

equipment and controls

can cause electrical arcs

that will ignite a flammable gas or

vapor. Never operate or repair in or

near a flammable gas or vapor. Never

store flammable liquids or gases in the

vicinity of the compressor.

Compressor parts may

be hot even if the unit

is stopped.

9. Keep fingers away from a running

compressor; fast moving and hot

parts will cause injury and/or burns.

10.If the equipment should start to

abnormally vibrate, STOP the

engine/motor and check

immediately for the cause. Vibration

is generally a warning of trouble.

11.To reduce fire hazard, keep

engine/motor exterior free of oil,

solvent, or excessive grease.

Never remove or

attempt to adjust

safety valve. Keep safety valve free

from paint and other accumulations.

Never attempt to repair

or modify a tank!

!

DANGER

!

WARNING

!

CAUTION

!

WARNING

Welding, drilling or any other

modification will weaken the tank

resulting in damage from rupture or

explosion. Always replace worn or

damaged tanks.

Drain liquid from

tank daily.

13.

Tanks rust from moisture build-up,

which weakens the tank. Make sure

to drain tank regularly and inspect

periodically for unsafe conditions

such as rust formation and corrosion

.

14. Fast moving air will stir up dust and

debris which may be harmful. Release

air slowly when draining moisture or

depressurizing the compressor system.

SPRAYING PRECAUTIONS

Do not spray flammable

materials in vicinity of

open flame or near

ignition sources including the

compressor unit.

15.Do not smoke when spraying paint,

insecticides, or other flammable

substances.

16.Use a face mask/

respirator when

spraying and spray in

a well ventilated area

to prevent health and

fire hazards.

17.Do not direct paint or other sprayed

material at the compressor. Locate

compressor as far away from the

spraying area as possible to

minimize overspray accumulation

on the compressor.

18.When spraying or cleaning with

solvents or toxic chemicals, follow

the instructions provided by the

chemical manufacturer.

Compressor handle has a notch (or

detent) at top of handle. This notch

provides a handy place to hang a spray

gun, sandblast gun, or other tool

equipped with a hook.

1. Insert handle into both sides of tank

baseplate at motor end. Handle must

fit into special openings in baseplate

and must be squeezed by hand to fit.

!

WARNING

NOTICE

2. Place a short piece of wood against

end of handle and tap it with a

mallet or hammer to drive handle

into baseplate until hole in handle

and baseplate line up (See Fig. 1).

3. Assemble and tighten screw (from

parts package) through hole in base-

plate ensuring it goes through handle.

Never use the

handle to lift the

unit completely off the ground. Only

use the handle to lift one end so the

wheels may be used to move the unit.

4. Spread openings in the rubber feet

and slip over ground iron. Position

the feet as shown in Fig. 1.

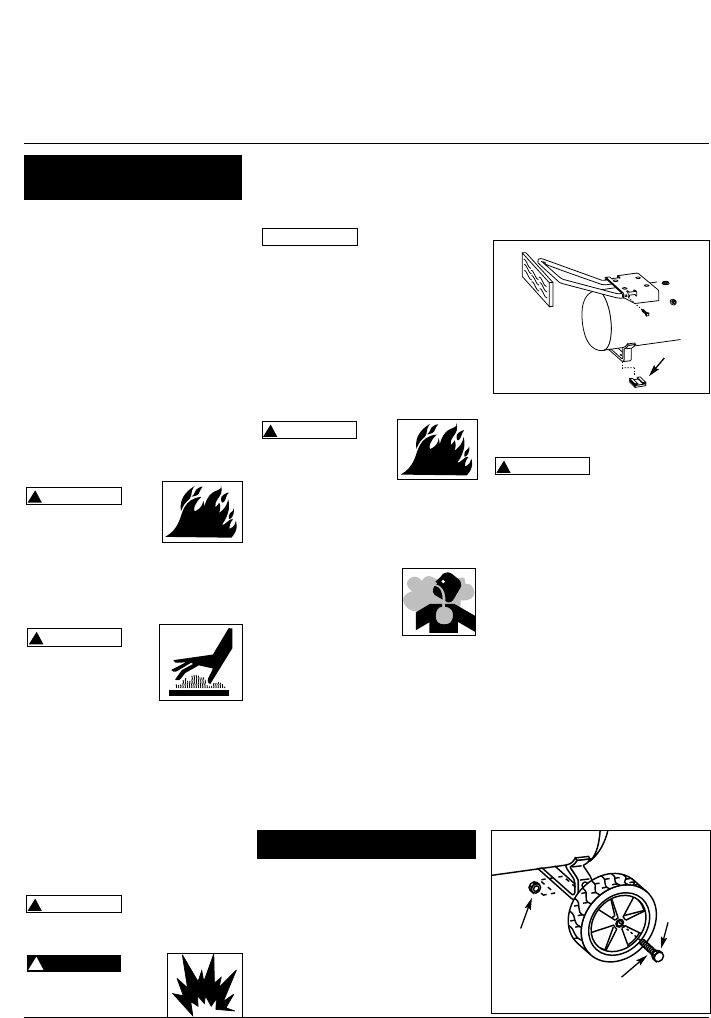

WHEEL ASSEMBLY

The items marked with an asterisk (*)

were shipped loose with the unit.

1. Insert shoulder bolt through wheel

hub. The bolt hex head should be

on the opposite side of protruding

hub center.

2. For 8 inch diameter wheels, feed

the shoulder bolt through the

bottom hole on the tank axle iron

and tightly secure with the locknut.

For 10 inch diameter wheels, feed

the shoulder bolt through the top

hole on the tank axle iron and

tightly secure with the locknut.

!

WARNING

Figure 1

Rubber

Foot

General Safety

Information (Continued)

Assembly

Shoulder

bolt

*

*

Figure 2 - Wheel Assembly

Lock nut

Wheel

www.chpower.com