Models WG3080, WG3090 and WG4130

9

www.chpower.com

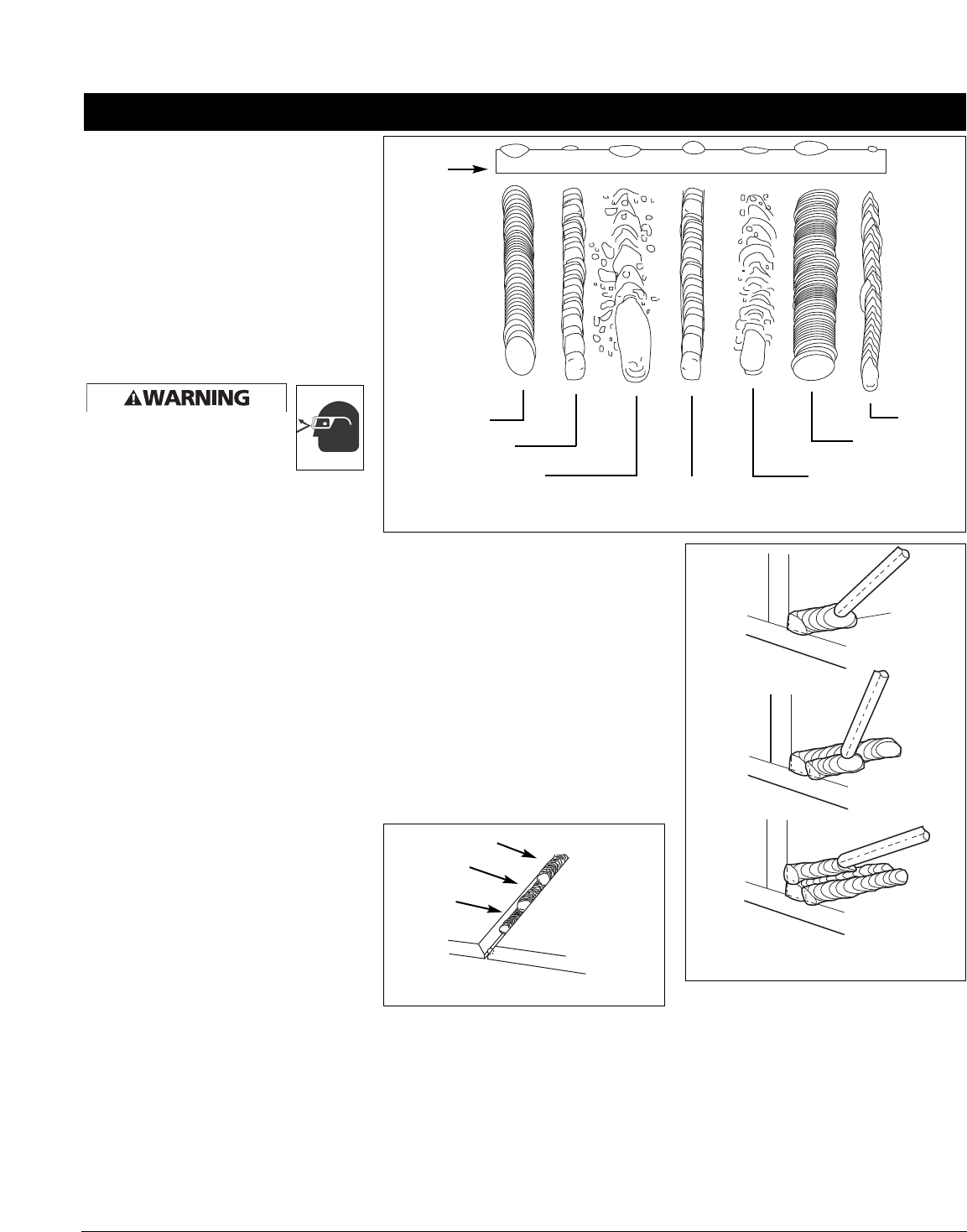

ELECTRODE EXTENSION

Electrode extension (or electrode stick-

out) is the distance between the end of

the contact tip and and the end of the

welding wire. The recommended

electrode extension is from 1/4 to 1/2 in

(6 to 13 mm). If the electrode extension

is too long, welding current will be

reduced and the bead will be high and

narrow with less penetration.

SLAG REMOVAL

(FLUX-CORED WIRE ONLY)

Wear ANSI approved safety

glasses (ANSI Standard Z87.1)

and protective clothing when

removing slag. Hot, flying

debris can cause personal injury to

anyone in the area.

After completing the weld, wait for the

welded sections to cool. A protective

coating called slag now covers the weld

bead which prevents contaminants in

the air from reacting with the molten

metal. Once the weld cools to the point

that it is no longer glowing red, the

slag can be removed. Removal is done

with a chipping hammer. Lightly tap

the slag with the hammer and break it

loose from the weld bead. The final

clean-up is done with a wire brush.

When making multiple weld passes,

remove the slag before each pass.

WELDING POSITIONS

Four basic welding positions can be used;

flat, horizontal, vertical, and overhead.

Welding in the flat position is easier than

any of the others because welding speed

can be increased, the molten metal has

less tendency to run, better penetration

can be achieved, and the work is less

fatiguing. Welding is performed with the

wire at a 45º travel angle and 45º work

angle.

Other positions require different

techniques such as a weaving pass,

circular pass, and jogging. A higher skill

level is required to complete these welds.

Overhead welding is the least desirable

position as it is the most difficult and

dangerous. Heat setting and wire selection

will vary depending upon the position.

All work should be performed in the

flat position if possible. For specific

applications, consult an arc welding

technical manual.

WELD PASSES

Sometimes more than one pass is

necessary to fill the joint. The root pass

is first, followed by filler passes and the

cover pass. If the pieces are thick, it

may be necessary to bevel the edges

that are joined at a 60º angle.

Remember to remove the slag before

each pass for the FCAW process.

Welding Guidelines (Continued)

Normal Heat,

Wire Speed,

Travel Speed

Heat Too Low

Heat Too High

Wire Speed

Too Fast

Wire Speed Too Slow

Travel Speed

Too Slow

Travel

Speed

Too Fast

Base

Metal

Figure 9 - Weld Appearance

Figure 10 - Weld Passes

Cover

Filler

Root

Figure 11 - Multiple Weld Passes