17

Remove

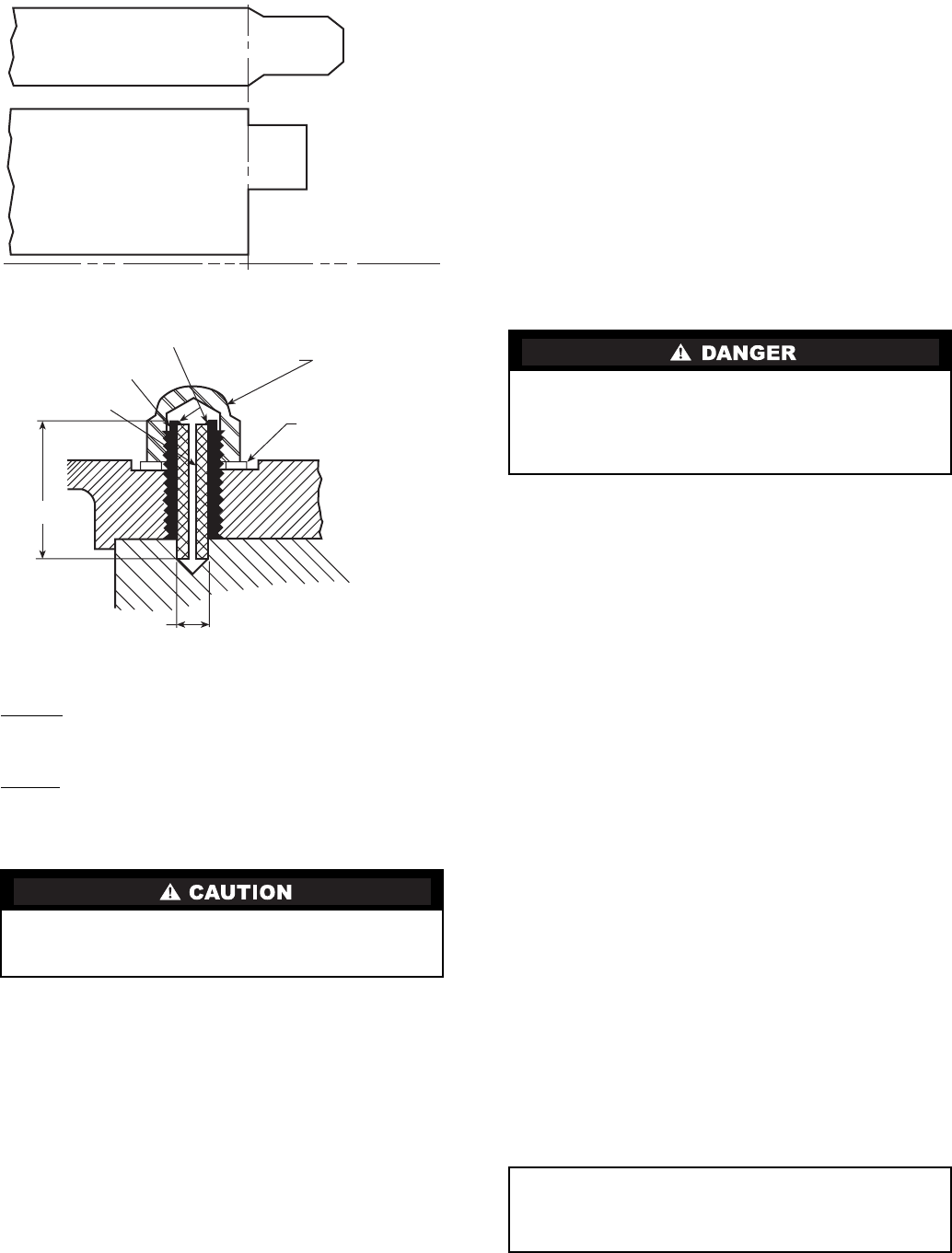

1. Acorn nut and washer.

2. Back out locking pin and bushing.

Replace

1. Screw in locking pin bushing until it rests on stator core.

2. Wrap a piece of tape around

3

/

8

-in. drill bit, 2

1

/

16

in. from

cutting edge.

3. Ream out bushing (

3

/

8

-in. drill) and drill into stator core

until tape is flush with top of bushing. (Remove drill

chips.) Back off locking pin bushing

1

/

8

of a turn.

4. Tap locking pin into position. (Top of bushing should be

approximately

1

/

16

in. above top of pin.)

5. Peen top of bushing over roll pin.

6. Replace washer and acorn nut.

Motor Burnout (Clean-Up Procedure) —

When a

hermetic motor burns out, the stator winding decomposes

forming carbon, water and acid which contaminate refrigerant

systems. Remove these contaminants from system to prevent

repeat motor failures.

1. Close compressor suction and discharge service valves,

and bleed refrigerant from compressor. Save remaining

refrigerant in system.

2. Remove burned motor from compressor, and drain com-

pressor oil. Clean crankcase and motor housing with

solvent. Ensure that all metal particles are wire-brushed

free and removed.

On severe burnouts, disassemble compressor heads and

valve plate assemblies. Clean them in same manner as

crankcase and motor housing.

3. Determine cause of burnout and remedy. Check control

box for welded starter contacts, welded overload contacts

or burned out heater elements. Check terminal plate for

burned or damaged terminals, insulation, and shorted or

grounded terminals.

4. Reassemble compressor with new stator and rotor. Install

new liquid line filter drier, and place new oil charge in

crankcase.

5. Evacuate and dehydrate compressor.

6. Place compressor in operation. After 2 to 4 hours of

operation, check compressor oil for discoloration and/or

acidity. If oil shows signs of contamination, replace oil

charge, filter driers, and clean suction strainer with

solvent.

7. Check oil daily for discoloration and acidity. If oil stays

clean and acid-free, the system is clean. If oil shows signs

of contamination, change oil, filter drier, and clean

suction strainer. If filter drier or suction strainer is dirty or

discolored, repeat this step until system is clean.

Condenser Maintenance (07E Units) —

To inspect

and clean condenser, drain water and remove condenser heads.

To drain condenser, shut off water supply and disconnect inlet

and outlet piping. Remove drain plugs and vent plug.

With condenser heads removed, inspect tubes for refrigerant

leaks. (Refer to Carrier Refrigerant Service Techniques Manual.)

Clean condenser tubes with nylon brush (available from

Carrier Service Department). Flush water through tubes while

cleaning. If hard scale has formed, clean tubes chemically. Do

not use brushes that will scrape or scratch tubes.

Because the condenser water circuit is usually an open

system, the condenser tubes may be subject to contamination

by foreign matter. Local water conditions may cause excessive

fouling or pitting of tubes. Condenser tubes, therefore, should

be cleaned at least once a year or more often if the water is

contaminated.

Proper water treatment can minimize tube fouling and

pitting. If such conditions are anticipated, water treatment

analysis is recommended. Refer to the Carrier System Design

Manual, Part 5, for general water conditioning information.

If hard scale has formed, clean the tubes chemically. Con-

sult an experienced and reliable water treatment firm in your

area for treatment recommendations. Clean the condenser by

gravity or by forced circulation as shown in Fig. 24 and 25.

Before drilling, be sure stator vent holes do not line up with

locking pin hole. Vent holes are drilled horizontally

through stator, and can be seen from end bell side.

Do not attempt start-up with terminal cover removed.

Bodily injury or death may result from explosion and/or

fire if power is supplied to compressor with the terminal

cover removed or unsecured. See warning label on termi-

nal cover.

IMPORTANT: If the ambient temperature is below 32 F

during a shutdown period, protect the condenser from

freezing by draining the water from the system or by add-

ing antifreeze to the water.

STATOR

END

TURN

ROTOR

END

RING

ROTOR CENTER LINE

PEENED ENDS

ACORN NUT

BUSHING

LOCKING PIN

WASHER

COMPRESSOR

CASTING

STATOR CORE

3/8"

2 1/16"

Fig. 22 — Motor Alignment

Fig. 23 — Stator Locking Assembly