SKU 94734 For technical questions, please call 1-800-444-3353. Page 7

SETUP

Dipstick

Warning: Fill compressor with oil before using; running with NO OIL or with LOW

OIL will void the warranty. The optimal capacity of the oil reservoir is 7.8 ounces of

oil.

The Dipstick is used to determine if oil is needed. Never operate the compressor with-

out sufcient oil. Use a 30 weight, non-detergent compressor oil. To check the oil:

1. Unscrew the Dipstick.

2. Check the level of the oil. There are two lines on the bottom of the Dipstick. The oil

level should be somewhere between the two lines, as high as possible.

3. Add oil through the Dipstick’s hole as necessary, but do not overll. Always use a high

grade oil specially designed for air compressors. Never mix oils of different types.

Never use a low quality oil which may not afford adequate lubrication.

4. Replace the Dipstick.

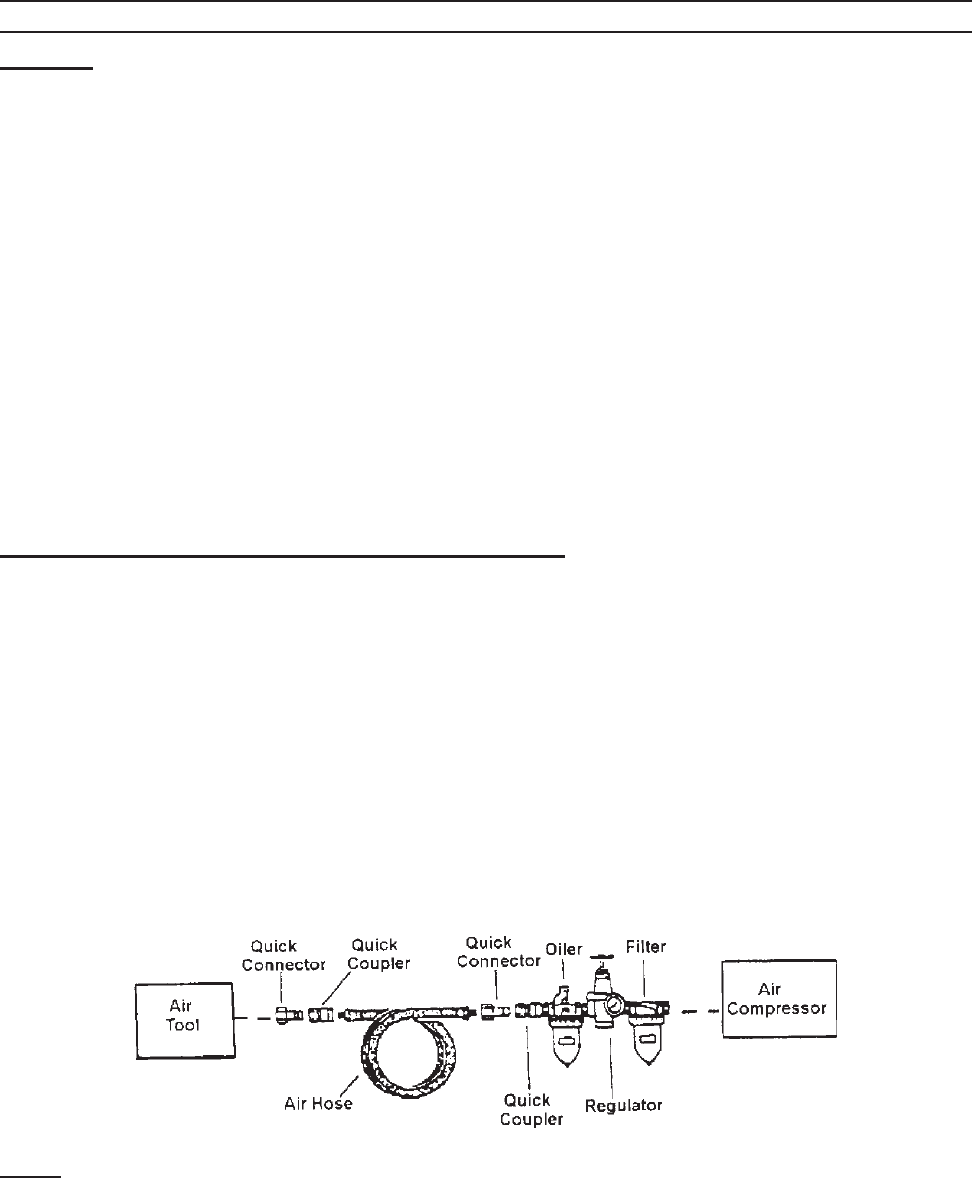

Install an Air Intake Filter and Hose (not included)

The lter and oiler (not supplied) are recommended but not mandatory for operation.

1. Remove and discard the plastic cap which covers the threaded hole at the top of the

Cylinder Case (B-6).

2. Screw the threaded part of the air lter assembly into the Cylinder Case until it is rmly

seated.

3. Connect the air tool, air hoses, lter, and oiler to the Compressor Air Output as

illustrated on the next page.

If the lter and oiler are not used, connect the air hose directly to the 1/4 inch NPT

barbed connector located at the Air Flow Valve (A-8). For easy connection or removal,

a quick coupler should be installed on the end of the air output.

Note: Use pipe thread seal tape on all threaded connections.