24

25

This saw has two scale indicators, one on the bevel scale

and one on the miter scale. After squaring adjustments

have been made, it may be necessary to loosen the indi-

cator screws and reset them to zero.

Fig. 31

VIEW OF BLADE NOT SQUARE WITH MITER

TABLE, ADJUSTMENTS ARE REQUIRED

ASSEMBLY

OPERATION

WARNING: Do not allow familiarity with tools to

make you careless. Remember that a careless frac-

tion of a second is sufficient to inflict severe injury.

WARNING: Always wear safety goggles or safety

glasses with side shields when operating tools. Fail-

ure to do so could result in objects being thrown into

your eyes resulting in possible serious injury.

WARNING: Do not use any attachments or acces-

sories not recommended by the manufacturer of

this tool. The use of attachments or accessories not

recommended can result in serious personal injury.

APPLICATIONS

This product has been designed only for the purposes

listed below:

n Cross cutting wood and plastic

n Cross cutting miters, joints, etc. for picture frames

moldings, door casings, and fine joinery

n Bevel cutting and compound cutting

NOTE: The blade provided is fine for most wood cutting

operations, but for fine joinery cuts or cutting plastic, use

one of the accessory blades available from your nearest

Sears retail store.

WARNING: Before starting any cutting operation,

clamp or bolt the compound miter saw to a work-

bench. Never operate the miter saw on the floor or in

a crouched position. Failure to heed this warning can

result in serious personal injury.

CUTTING WITH THE COMPOUND MITER

SAW

WARNING: When using a work clamp or C-clamp

to secure the workpiece, clamp workpiece on one

side of the blade only. The workpiece must remain

free on one side of the blade to prevent the blade

from binding in workpiece. The workpiece binding

the blade will cause motor stalling and kickback.

This situation could cause an accident resulting in

possible serious personal injury.

CROSSCUTTING

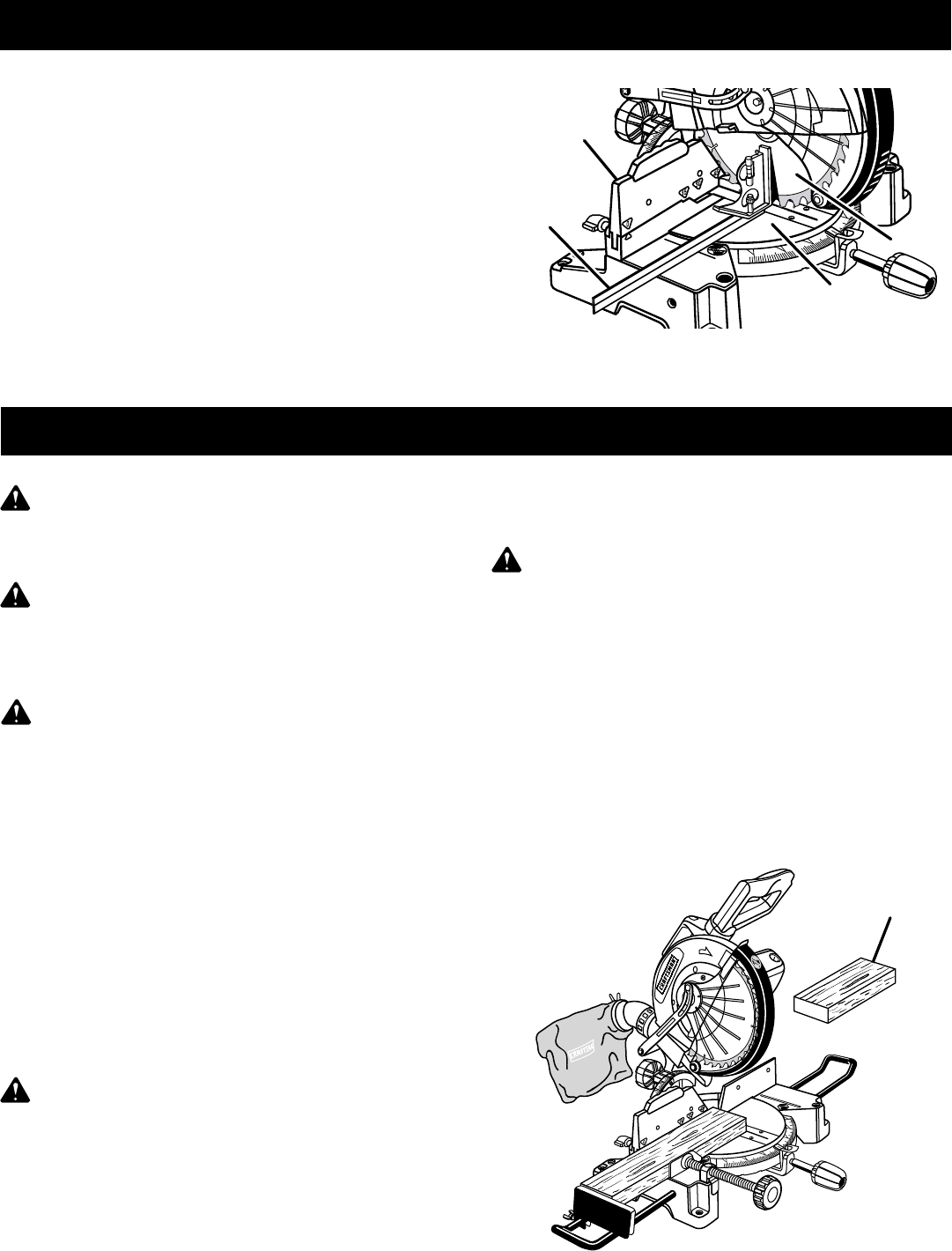

See Figure 32.

A crosscut is made by cutting across the grain of the

workpiece. A straight crosscut is made with the miter

table set at the 0

°

position. Miter crosscuts are made with

the miter table set at some angle other than zero.

STRAIGHT

CROSSCUT

Fig. 32

FENCE

MITER

TABLE

BLADE

COMBINATION

SQUARE