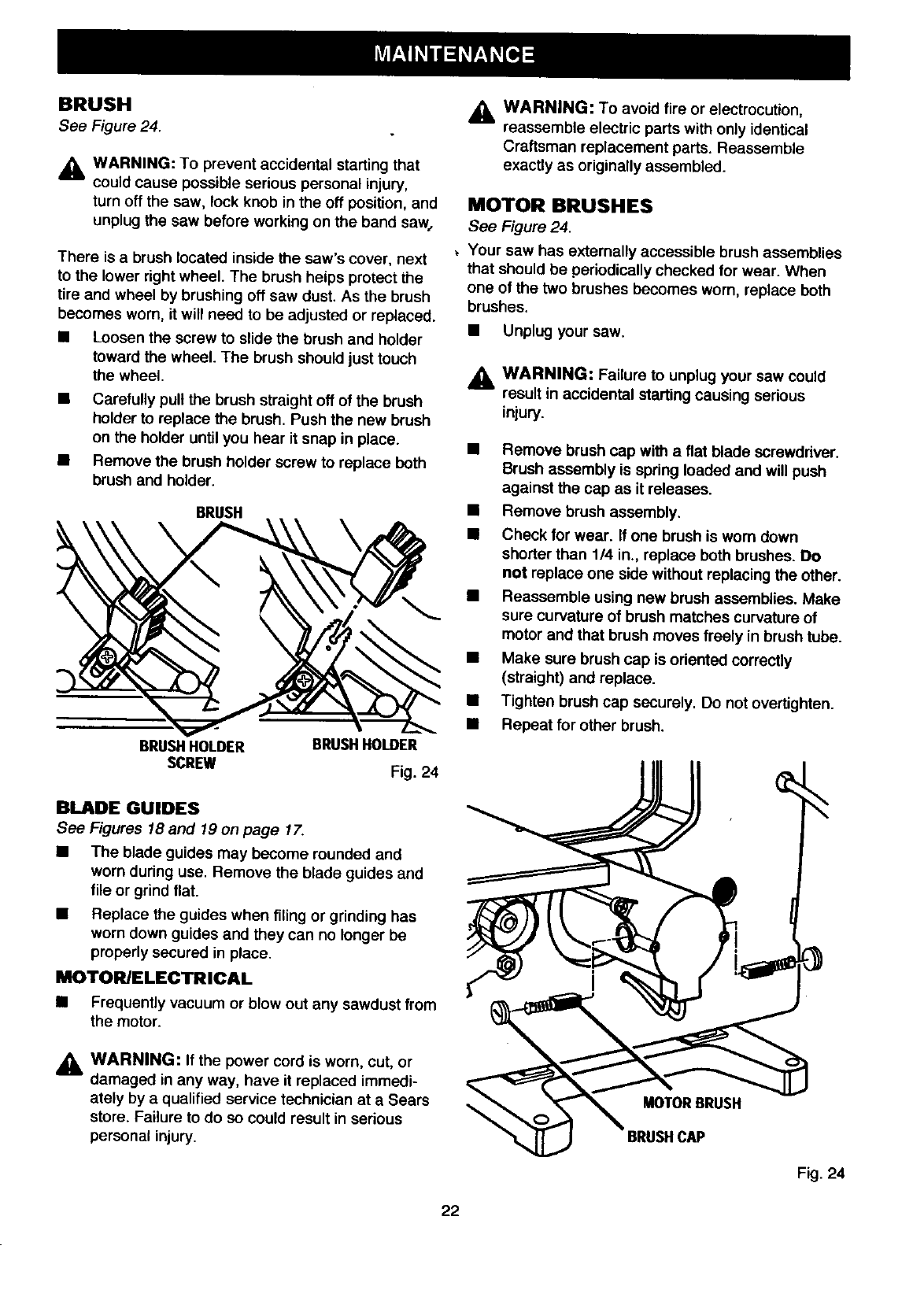

BRUSH

See Figure 24.

_k WARNING: To prevent accidental starting that

could cause possible serious personal injury,

turn off the saw, lock knob in the off position, and

unplug the saw before working on the band saw,

There is a brush located inside the saw's cover, next

to the lower right wheel. The brush helps protect the

tire and wheel by brushing off saw dust. As the brush

becomes worn, it will need to be adjusted or replaced.

• Loosen the screw to slide the brush and holder

toward the wheel. The brush should just touch

the wheel.

• Carefully pull the brush straight off of the brush

holder to replace the brush. Push the new brush

on the holder until you hear it snap in place.

• Remove the brush holder screw to replace both

brush and holder.

BRUSH

BRUSHHOLDER BRUSHHOLDER

SCREW Fig. 24

BLADE GUIDES

See Figures 18 and 19 on page 17.

• The blade guides may become rounded and

worn during use. Remove the blade guides and

file or grind flat.

• Replace the guides when filing or grinding has

worn down guides and they can no longer be

properly secured in place.

MOTOR/ELECTRICAL

• Frequently vacuum or blow out any sawdust from

the motor.

_1, WARNING: If the power cord is worn, cut, or

damaged in any way, have it replaced immedi-

ately by a qualified service technician at a Sears

store. Failure to do so could result in serious

personal injury.

,_, WARNING: To avoid fire or electrocution,

reassemble electric parts with only identical

Craftsman replacement parts. Reassemble

exactly as originally assembled.

MOTOR BRUSHES

See Figure 24.

Your saw has externally accessible brush assemblies

that should be periodically checked for wear. When

one of the two brushes becomes worn, replace both

brushes.

• Unplug your saw.

,_ WARNING: Failure to unplug your saw could

result in accidental starting causing serious

injury.

• Remove brush cap with a flat blade screwdriver.

Brush assembly is spring loaded and will push

against the cap as it releases.

• Remove brush assembly.

• Check for wear. If one brush is worn down

shorter than 1/4 in., replace both brushes. Do

not replace one side without replacing the other.

• Reassemble using new brush assemblies. Make

sure curvature of brush matches curvature of

motor and that brush moves freely in brush tube.

• Make sure brush cap is oriented correctly

(straight) and replace.

• Tighten brush cap securely. Do not overtighten.

• Repeat for other brush.

Fig. 24

22