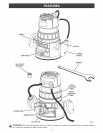

DIRECTION(INTERNAL)

Wheneveryouareroutingagroove,yourtravel

shouldbeina directionthatplaceswhateverguide

youareusingattheright-handside.Inshort,when

theguideispositionedasshowninthefirstpartof

Figure13,tooltravelshouldbeleftto rightand

counterclockwisearoundcurves.Whentheguideis

positionedasshowninthesecondpartof Figure13,

tooltravelshouldberighttoleftandclockwisearound

curves.Rfthereisachoice,thefirstsetupisgenerally

theeasiesttouse.Ineithercase,thesidewaysthrust

youuseisagainsttheguide.

GUIDEOUTSIDE

ROTATION

THRUST

ROTATION

FEED

GUIDE

GUIDEINSIDE

ROTATIONC_

GUIDE@ ÷

ROTAT OH /

FEED

THRUST

Fig. 13

DETERMINING DEPTH OF CUT

As previously mentioned, the depth of cut is important

because it affects the rate of feed that, in turn, affects

the quality of the cut (and, also, the possibility of

damage to your router motor and bit). A deep cut

requires a slower feed than a shallow one, and a too

deep cut will cause you to slow the feed so much that

the bit is no longer cutting, it is scraping, instead.

Making a deep cut is never advisable. The smaller

bits -- especially those only 1/16 inch (1.6 mm) in

diameter -- are easily broken off when subjected to

too much side thrust. A large enough bit may not be

broken, but if the cut is too deep a rough cut will result

-- and it may be very difficult to guide and control the

bit as desired. For these reasons, we recommend that

you do not exceed 1/8 in. depth of cut in a single

pass, regardless of the bit size or the softness or

condition of the workpiece. See FiXTure14.

To make deeper cuts it is therefore necessary to

make as many successive passes as required,

lowering the bit 1/8 in. for each new pass. In order to

save time, do all the cutting necessary at one depth

setting, before lowering the bit for the next pass. This

will also assure a uniform depth when the final pass is

completed. See FiXTure 15.

DEPTH

OFCUT

__ WIDTH

Fig. 14

1ST.

2HD. [7 PASS

PASS _U m

2ND.PASS

Fig. 15

15