17 - ENG

N014212

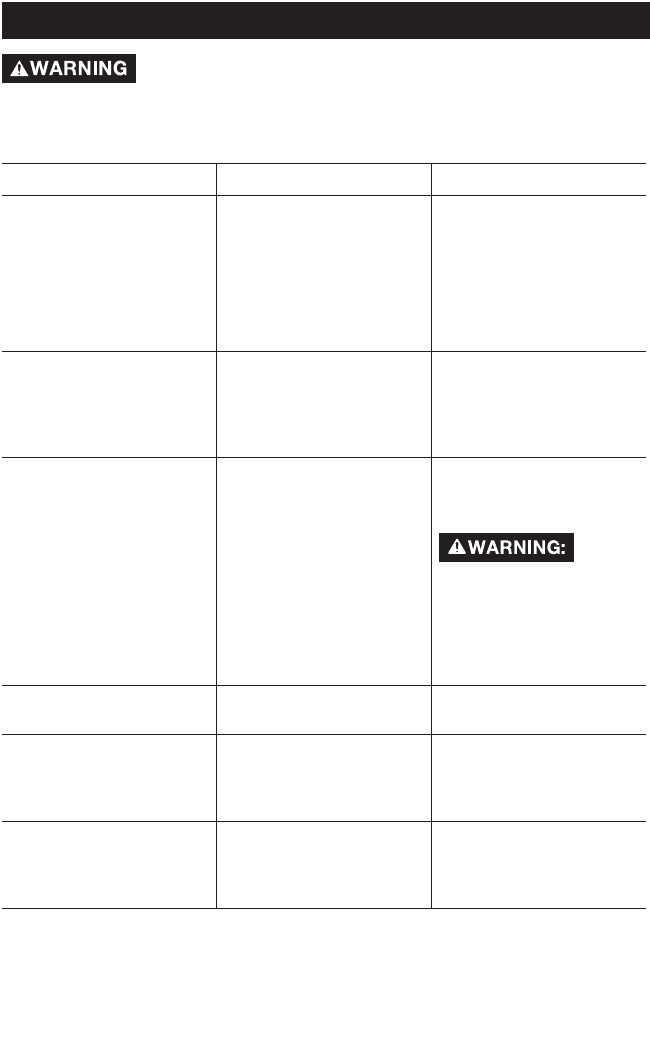

PROBLEM CORRECTION

Excessive tank pressure

- safety valve pops off.

Pressure switch does

not shut off motor when

compressor reaches

"cut-out" pressure.

Move On/Off lever to

the "Off" position, if

the outfit does not shut

off contact a Trained

Service Technician.

Pressure switch "cut-

out" too high.

Contact a Trained

Service Technician.

Air leaks at fittings. Tube fittings are not tight

enough.

Tighten fittings where air

can be heard escaping.

Check fittings with

soapy water solution. Do

Air leaks in air tank or at

air tank welds.

Defective air tank. Air tank must be

replaced. Do not repair

the leak.

not drill into, weld or

tank or it will weaken.

Air leaks between head

and valve plate.

Leaking seal. Contact a Trained

Service Technician.

Air leak from safety

valve.

Possible defect in safety

valve.

Operate safety valve

manually by pulling on

ring. If valve still leaks, it

should be replaced.

KnockingNoise. Possible defect in safety

valve.

Operate safety valve

manually by pulling on

ring. If valve still leaks, it

should be replaced.