Maintenance

NOTE: Any service procedure not covered in the maintenance schedule below should be performed by qualified service

)ersonnel.

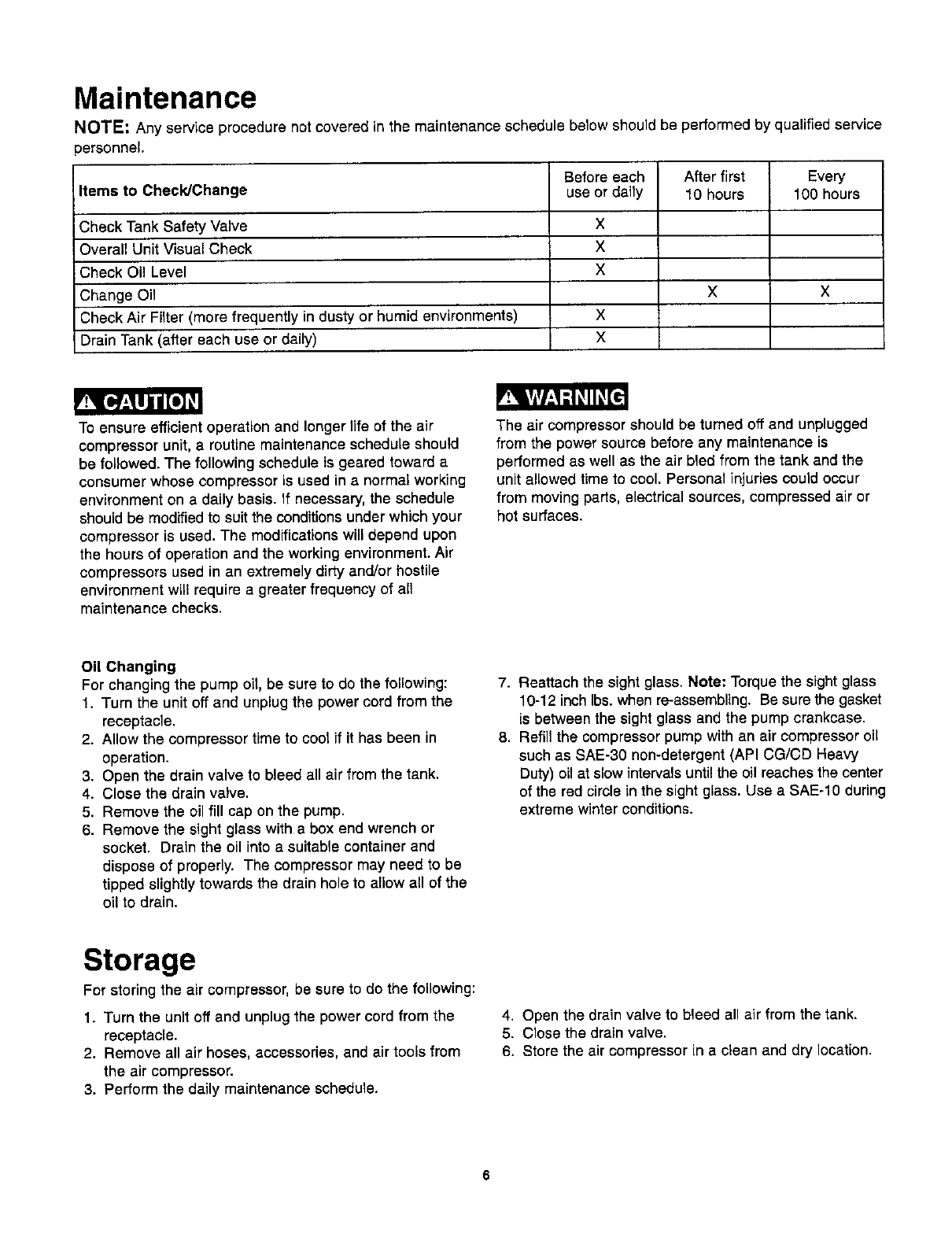

Items to Check/Change

Check Tank Safety Valve

Overall Unit Visual Check

Check Oil Level

Change Oil

Check Air Filter (more frequently in dusty or humid environments)

Drain Tank (after each use or daily)

Before each

use or daily

X

X

X

X

X

After first

10 hours

X

Every

100 hours

To ensure efficient operation and longer life of the air

compressor unit, a routine maintenance schedule should

be followed. The following schedule is geared toward a

consumer whose compressor is used in a normal working

environment on a daily basis. If necessary, the schedule

should be modified to suit the conditions under which your

compressor is used. The modifications will depend upon

the hours of operation and the working environment. Air

compressors used in an extremely dirty and/or hostile

environment will require a greater frequency of all

maintenance checks.

The air compressor should be turned off and unplugged

from the power source before any maintenance is

performed as well as the air bled from the tank and the

unit allowed time to cool. Personal injuries could occur

from moving parts, electrical sources, compressed air or

hot surfaces.

Oil Changing

For changing the pump 0il, be sure to do the following:

1. Turn the unit off and unplug the power cord from the

receptacle.

2. Allow the compressor time to cool if it has been in

operation.

3. Open the drain valve to bleed all air from the tank.

4. Close the drain valve.

5. Remove the oil fill cap on the pump.

6. Remove the sight glass with a box end wrench or

socket. Drain the oil into a suitable container and

dispose of properly. The compressor may need to be

tipped slightly towards the drain hole to allow all of the

oil to drain.

7. Reattach the sight glass. Note: Torque the sight glass

10-12 inch Ibs. when re-assembling. Be sure the gasket

is between the sight glass and the pump crankcase.

8. Refill the compressor pump with an air compressor oil

such as SAE-30 non-detergent (API CG/CD Heavy

Duty) oil at slow intervals until the oil reaches the center

of the red circle in the sight glass. Use a SAE-10 during

extreme winter conditions.

Storage

For storingthe air compressor, be sure to do the following:

1. Turn the unit off and unplug the power cord from the

receptacle.

2. Remove all air hoses, accessories, and air tools from

the air compressor.

3. Perform the daily maintenance schedule.

4. Open the drain valve to bleed all air from the tank.

5. Close the drain valve.

6. Store the air compressor in a clean and dry location.