AN2309

November 25, 2007 Document No. 001-17394 Rev. *B - 3 -

Temperature gradient across the battery pack.

Temperature mismatches of 15 degrees Celsius can

cause up to 5- percent capacity differential among cells.

Such a temperature gradient is relatively common in

densely packed products, where multiple heat sources

are located close to the battery pack. An example of

this is a laptop computer.

The main causes of variation in cell charge levels are:

Variations in self-discharge rates. Even at room

temperature, two similar cells self-discharge at different

rates, resulting in a mismatch. For example, one cell

could lose 3 percent per month, while another cell loses

a different amount.

Variations in internal cell impedance. These impedance

variations cause otherwise similar battery cells to have

different charge acceptance levels. This error is minute

(about 0.1 percent).

Cell balancing is achieved by connecting a parallel load to

each cell that must be balanced. Typically, a series

combination of a power transistor (MOSFET) and a current-

limiting resistor are connected in parallel to each cell. If a

cell has a higher voltage than the other cells, the bypass

load to the cell is connected by closing the MOSFET so that

a fraction of the charging current bypasses that cell. It is

possible to balance the cells during the discharge phase, the

charge phase, or both phases.

Balancing the charge levels among cells must be done

during the charge or discharge phase. This balancing

process is simple and has been well investigated. Balancing

the cells’ capacity variation must be done during both the

charge and discharge phases. Cells with different capacities

must be charged or discharged by using an absolute value

rather than a relative value. The process of balancing cell

capacity variation is difficult to implement in practice and is

not intuitively obvious.

The charge in dV/dQ for Li-Ion batteries has a maximum

level when the cells are nearly fully charged or discharged. It

takes less time to correct voltage mismatch during this

period of complete or nearly complete charge/discharge

than during the middle period of battery charge/discharge.

Thus, it is advisable to perform the balancing routine when

the cells are nearly fully charged or nearly fully discharged.

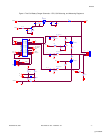

See also Cell-Balancing Algorithm on page 14. The cell-

balancing technique is shown in Figure 1.

Figure 1. Cell-Balancing Technique Schematic

Charger,

Monitor,

Safety,

Fuel Gauge,

Cell Balance

Software

Load

R1

R2

Q1

Q2

CELL1

CELL2

The balancing circuit is represented by (R1, Q1) and (R2,

Q2). These transistors and resistors dissipate energy and

control the amount of balancing current.

If cell balancing is performed during the charge phase, the

charge current on the balanced cells is reduced on the

shunted current value (Equation 7 and Equation 8) and

remains unchanged on other cells:

V

cellN

I

balN

RR

N QN

Equation 7

I I I

chargeN charge balN

Equation 8

The value

I

balN

is the current that flows through the

balancing circuit of the cell N, and

V

cellN

is the battery

electro chemical potential. The value

R

N

is the balancing

resistor, and

R

QN

is the transistor resistance. The value

I

chargeN

is the charge current of cell N, and

I

charg e

is

the battery pack charge current.

If cell balancing is performed during the discharge phase,

the current that flows through the balancing circuit depends

on the system load resistance. If the load resistance is high,

by comparison with a balancing circuit resistance, most of

the discharge current flows through the balancing circuit. But

if the load resistance is low, most of the discharge current

flows through the load, making the balancing operation less

efficient.

The current that flows through the balancing circuit is shown

in Equation 7 and the equivalent discharge resistance is

equated as:

()R R R

N QN load

R

dischargeN

R R R

N QN load

Equation 9

The value

R

dischargeN

is the equivalent discharge

resistance of the balanced cell N, and

R

load

is the load

resistance.

Components for the cell-balancing circuit are selected by

taking the following factors into account:

Amount of Imbalance: This factor is described earlier

in this section and consists of variations in capacity and

charge level. Typically, cell imbalance is about 1

percent. An imbalance as great as 5 percent to 15

percent can occur only with a high temperature gradient

or if a battery pack has been stored and not used for a

long period of time.

[+] Feedback