21

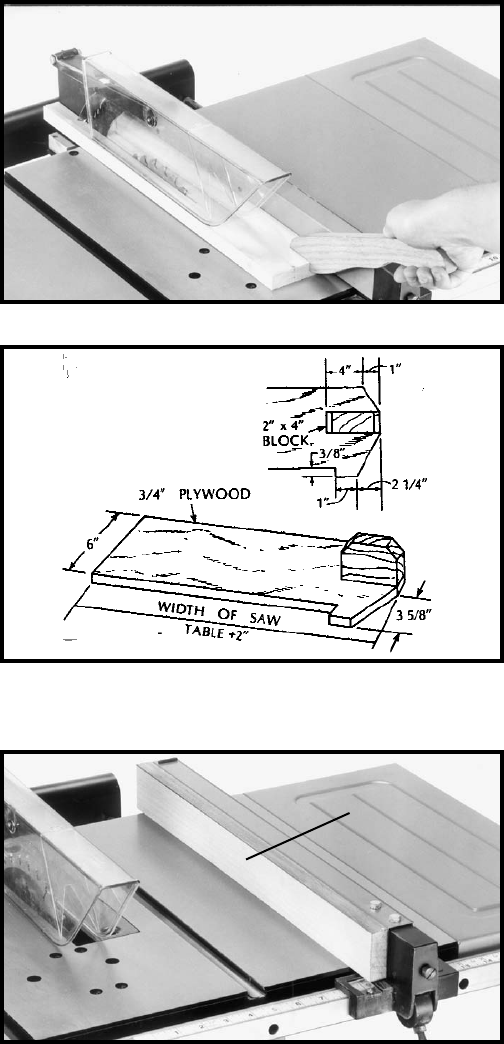

If the ripped work is less than 4 inches wide, a push stick

should always be used to complete the feed, as shown

in Fig. 124. The push stick can easily be made from scrap

material as explained in the section “CONSTRUCTING A

PUSH STICK.”

When ripping material under 2 inches in width, a flat

pushboard is a valuable accessory since ordinary type

sticks may interfere with the blade guard. That flat

pushboard can be made as shown in Fig. 58.

USING AUXILIARY WOOD

FACING ON RIP FENCE

It is necessary when performing some special

operations to add wood facing (A) Fig. 59, to one or both

sides of the rip fence, as shown. The wood facing is

attached to the fence with wood screws through the

holes in the fence. 3/4 inch stock is suitable for most

work although an occasional job may require 1 inch

facing.

A wood facing should be used when ripping material

such as thin paneling to prevent the material from

catching between the bottom of the rip fence and the

saw table surface.

Further information on the safe and proper operation of

table saws is available in the Delta “Getting the Most Out

of Your Table Saw” How-To-Book, Catalog No. 11-400.

Additional information on table saw safety is also

available by writing to:

NATIONAL SAFETY COUNCIL

1121 Spring Lake Drive

Itasca, IL 60143-3201

Fig. 57

Fig. 59

A

Fig. 58