12

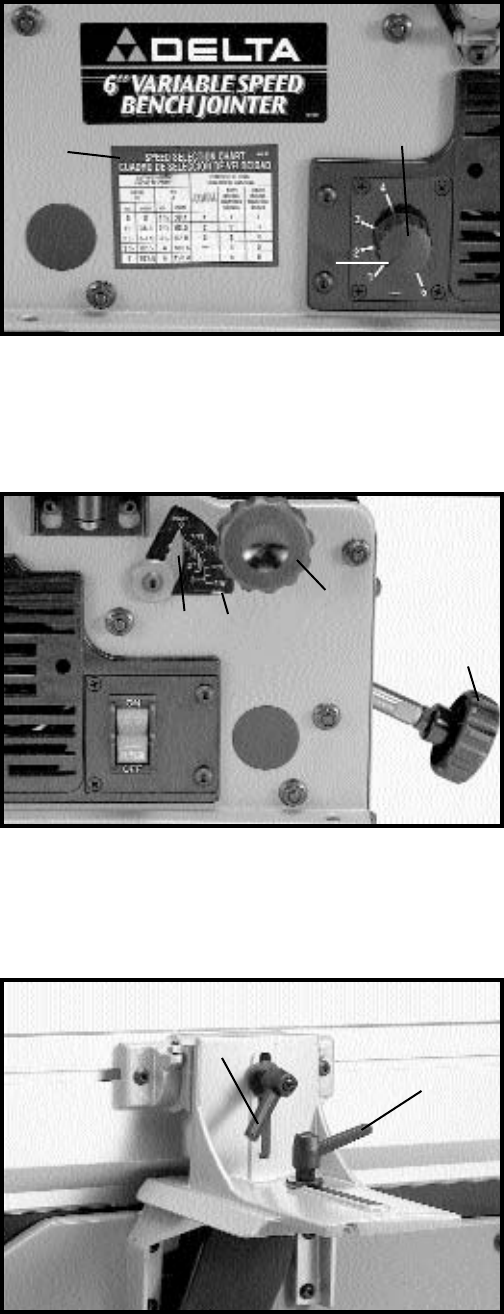

VARIABLE SPEED CONTROL

Your jointer is supplied with a variable speed control

knob (A) Fig. 23, that enables you to operate the machine

at cutterhead speeds between 6000 and 11,000 RPM.

Speed indicators of 1-2-3-4 and 5 are provided on the

speed dial as shown. When the pointer (B) is pointing to

1, the cutterhead speed will be 6000 RPM; 2 – 7250

RPM; 3 – 8800 RPM; 4 – 9750 RPM; and 5 – 11,000

RPM.

SPEED CONTROL CHART

A speed control chart (C) Fig. 23, indicates the recom-

mended cutterhead speed setting when jointing plastics,

soft woods and hard woods from 1-1/2" to 6" wide.

DEPTH OF

CUT ADJUSTMENT

The jointer can be set to cut any depth from a very thin

shaving to 1/8" deep. A dual English/Metric scale (A)

Fig. 24, and pointer (B) are provided to indicate the depth

of cut. To adjust for depth of cut, loosen lock knob (C)

and turn adjusting knob (D) clockwise to lower and coun-

terclockwise to raise the infeed table. After the infeed

table is at the desired setting, tighten lock knob (C).

NOTE: For best results, final positioning of the infeed

table should always be made from the bottom to the up

position.

FENCE ADJUSTMENTS

The fence can be moved across the table and can be

tilted up to 45 degrees to the right, as follows:

1. To move the fence across the table, loosen lock lever

(A) Fig. 25, slide the fence to the desired position on the

table and tighten lever (A). NOTE: Lock lever (A) is spring

loaded and can be repositioned by pulling up on the

lever and repositioning it on the nut located underneath

the lever.

2. To tilt the fence, loosen lever (B) Fig. 25, and tilt the

fence to the desired angle. Then tighten lever (B). NOTE:

Lever (B) is spring loaded and can be repositioned by

pulling out on the lever and repositioning it on the nut

located underneath the lever.

Fig. 23

Fig. 24

Fig. 25

C

A

B

D

C

A

B

A

B