15

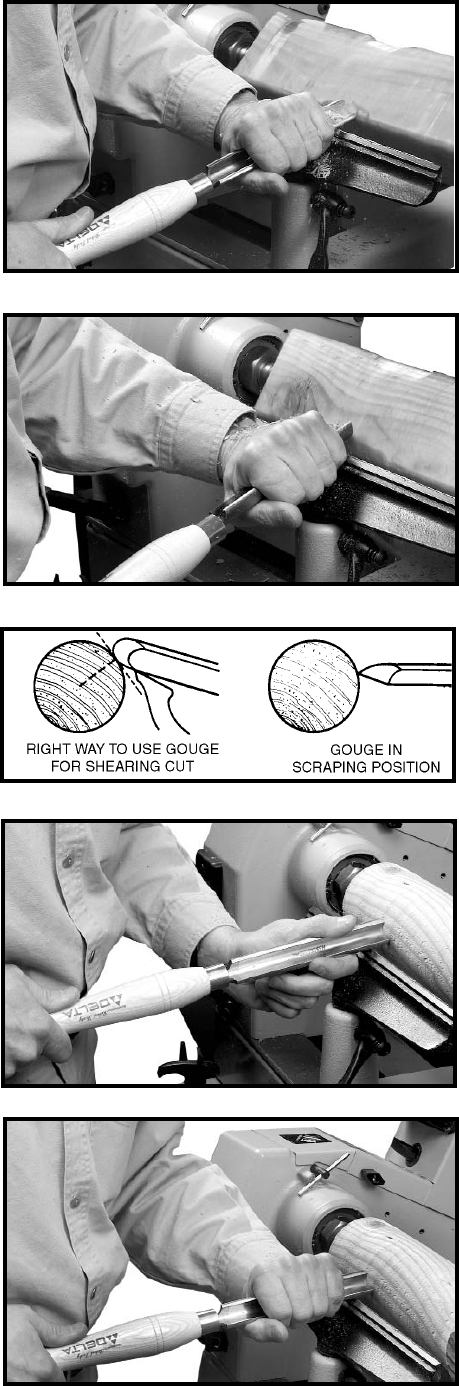

Fig. 33

Fig. 34

Fig. 35

ROUGHING A CYLINDER

The large gouge is used in the first turning operation by

smoothing the sharp corners of the work. Run the lathe at

low speed and hold the gouge in the manner shown in

Fig. 33 The cut starts about 2 inches from the tailstock

end and continues from this point to the end of the tail-

stock. Make the second pass beginning about 2” or 3” to

the left of the first cut. Advance again toward the tailstock,

and merge with the previous cut. Toward the end of the

live center, roll the gouge in the opposite direction

(Fig. 34) to carry the final cut off the live center end of the

work. The roughing cut should not be carried out with one

continuous movement, because this would tear long

slivers from the corners of the work. Neither should the

cut be started directly at the end of the stock for the

same reason. The cut can be safely carried from the

center of the stock toward and off either end once the first

roughing cuts have been made.

The position of the gouge involves two or three important

angles. (1) The tool may be advanced along the work

either from right to left or from left to right. Left to right

(from headstock to tailstock) is preferred since this action

throws chips clear of the operator. (2) The gouge is rolled

over slightly in the same direction it is advancing. (3) The

tool is held well up on the work, with the bevel or grind

tangent to the revolving surface (Fig. 35). This position will

give a clean shearing cut. When pushed straight into the

work (Fig. 35), the gouge has a scraping action, (normally

a poor practice in spindle turning). The roughing cut is

continued until the work approaches 1/8” of the required

diameter. Once a cylindrical form has been obtained, the

turning speed can be moved to the second or third speed

setting. NOTE: Continue to move the tool rest inward

toward the work piece to keep the safe distance between

the two.

POSITION OF HANDS

While turning, the hand that holds the tool handle

should be in a natural position. This hand provides the

leverage for the tool by either moving in toward the

chisel or moving out. The position of the tool rest hand is

more a matter of individual preference, rather than a “set”

or “proper” position. However, a palm-up grip (Fig. 36) is

generally considered best. In this position, the first finger

acts as a guide, sliding along the tool rest as the cut is

made. The alternate position is a palm-down grip (Fig.

37). In this position, the heel of the hand or the little finger

serves as a guide. The palm-down position is solid and

positive – excellent for roughing or heavy cutting. Most

beginners start with the palm-down grip, switching later

to the palm-up position for better manipulation of the

chisel.

Fig. 37

Fig. 36