13

OPERATIONAL CONTROLS AND

ADJUSTMENTS

OPERATION

Fig. 25

Fig. 24

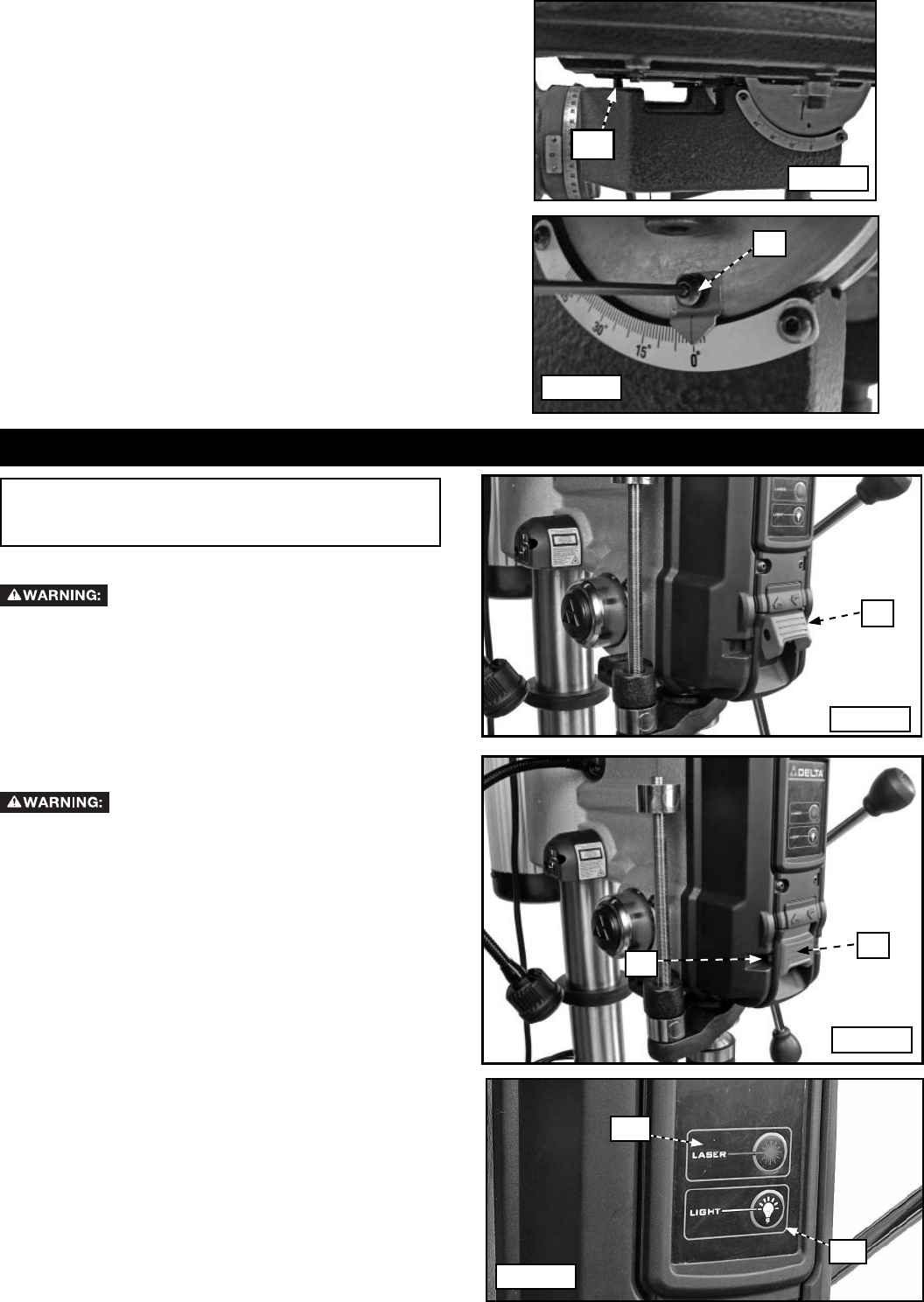

STARTING AND STOPPING 18-900L

To reduce the risk of injury, make sure

that the ON/OFF switch is in the "OFF" position before

plugging cord into outlet. Do not touch the plug’s metal

prongs when unplugging or plugging in the cord.

To turn drill press on, lift switch paddle (KK) Fig. 24 up

to the "ON" position. To turn drill press off, push switch

paddle (KK) Fig. 25 down to the "OFF" position, as

shown.

LL

KK

KK

LOCKING SWITCH IN THE "OFF" POSITION

To reduce the risk of injury, in the event

of a power outage (such as a breaker or fuse trip),

always move the switch to the “OFF” position until

the main power is restored.

IMPORTANT: When the machine is not in use, the

switch should be locked in the "OFF" position to prevent

unauthorized use, using a padlock through holes at (LL) Fig.

25. The minimum shackle diameter should be 1/5" (5 mm)

and minimum shackle length should be 7/8” (22.2 mm).

Fig. 26

MM

NN

TURNING ON WORK LIGHT AND LASERS

Push "LASER" button (MM) Fig. 26 to turn on or turn off

the crosshair lasers.

Push "LIGHT" button (NN) Fig. 26 to turn on or turn off

the LED work light.

TABLE TILT POINTER

Lock the forward tilt knobs with the table firmly against

the set screw (Y1) Fig. 23D.

Place the lockwasher under the screw head (Z1)

Fig. 23E and then the pointer. Align the indicator line

on the pointer with 0° mark on the scale and tighten

securely with supplied hex wrench.

Y1

Fig. 23D

Fig. 23E

Z1