18

CHANGING SPEEDS AND ADJUSTING BELT

TENSION

To reduce the risk of injury, turn unit off

and disconnect it from power source before installing

and removing accessories, before adjusting or when

making repairs. An accidental start-up can cause injury.

NOTE: Sixteen spindle speeds are available on the drill

press. A belt-positioning speed chart is located on the

inside top cover of the drill press.

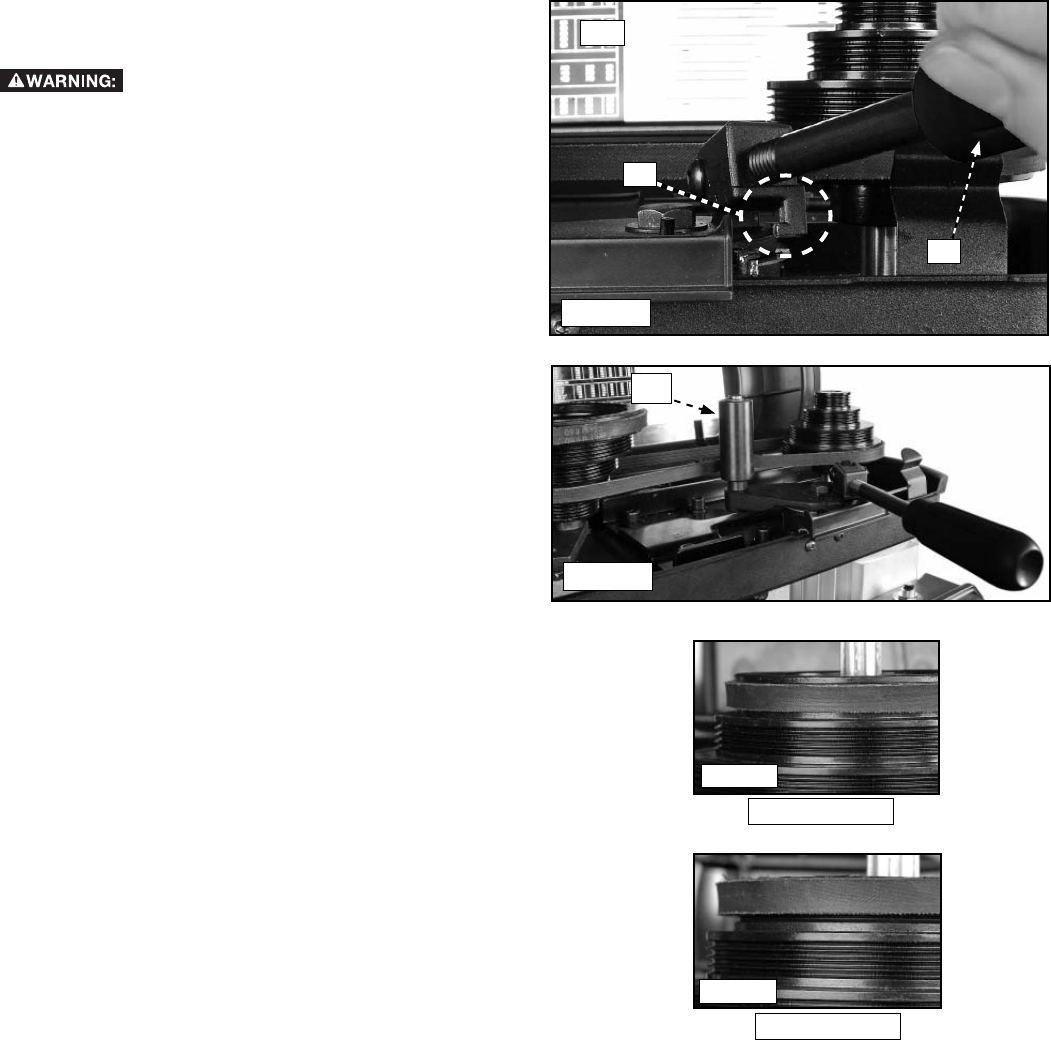

1. Lift cover (H1) Fig. 39.

2. Move belt tension lever handle (I1) Fig. 39 up and to

the right and engage the hook (J1) Fig. 39 (inset) to

hold the tensioner arm in place.

3. Choose the appropriate speed for the tool you

are using and position the belts on the pulleys

accordingly. See chart (Fig. 38) on the inside cover

of the drill press head.

4. NOTE: The belts are ribbed with grooves, so make

sure the belt grooves match up with the pulley

grooves.

5. Lift handle and move to left (as shown in Fig. 40)

until the belt tensioner arm (K1) rests against the

belts.

NOTE: Don't force the handle any further to the left. It is

set with the proper tension for the belts.

NOTE: Fig. 41 shows the proper seating for the top belt,

with the small bit of metal showing above the black belt.

Fig. 42 shows improper seating for the top belt with no

metal showing above the black belt.

Fig. 40

Fig. 39

H1

I1

Fig. 42

Fig. 41

K1

CORRECT

INCORRECT

J1