12

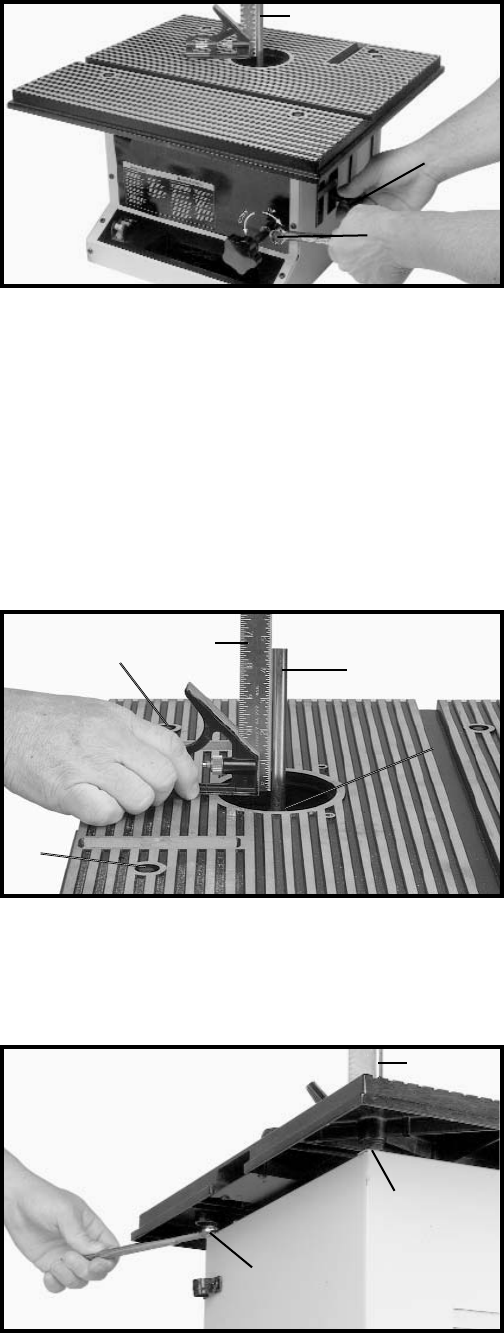

5. Loosen adjustment bolt (D) Fig. 24, and

corresponding bolt at the rear of the machine (not

shown.).

6. Carefully move the spindle height lock knob (E) Fig.

24, up or down until the metal rod (A) is 90 degrees to

the table surface. Then tighten adjustment bolts (D)

which were loosened in STEP 5.

Fig. 24

A

E

D

Fig. 25

Fig. 26

E

E

C

A

B

A

G

F

ADJUSTING TABLE 90

DEGREES (FRONT AND

BACK) TO THE SPINDLE

The table has been adjusted at the factory so the table

surface is 90 degrees, front and back, to the spindle and

further adjustment should not be necessary. However,

rough handling during shipment or repair or replacement

of certain components might disturb this setting. To

check and adjust the table surface 90 degrees (front and

back) to the spindle, proceed as follows:

1. DISCONNECT MACHINE FROM POWER SOURCE.

2. Tighten the spindle height lock knob.

3. Insert a “straight” section of 1/2 inch diameter metal

rod (A) Fig. 25, which is at least 6 inches in length, into

router collet (B), and tighten collet (B) as you would a

router bit.

4. Using a square (C) Fig. 25, either on the front or rear

of the table, place one end of the square against the

metal rod (A) as shown. Check to see if the table surface

is 90 degrees to metal rod (A) (front to back). If an

adjustment is necessary, proceed as follows:

5. Loosen two screws (E) Fig. 25, that fasten the rear of

the table to the cabinet.

6. Rotate leveling nut (F) Fig. 26, which is located at the

rear of the machine and under the table

counterclockwise as far it it will go up into the table.

7. Rotate leveling nut (G) Fig. 26, right or left until table

surface (front and back) is 90 degrees to metal rod (A).

8. Turn leveling nut (F) Fig. 26, clockwise until it just

contacts top of cabinet.

9. Tighten two screws that were loosened in STEP 5.