15

OPERATION

The following is an example of the setting-up and operational procedures when using the fence, collars and

starting pin. Please review this information carefully before turning on the power to avoid damage to the

machine or personal injury. WARNING: The use of accessories and attachments not recommended by Delta may

result in risk of injuries.

ROUTING OR SHAPING

WHEN USING THE FENCE

AS A GUIDE

Using the fence is the safest and most satisfactory

method of shaping and routing and this method should

always be used when the work permits. Almost all

straight work can be shaped using the fence as follows:

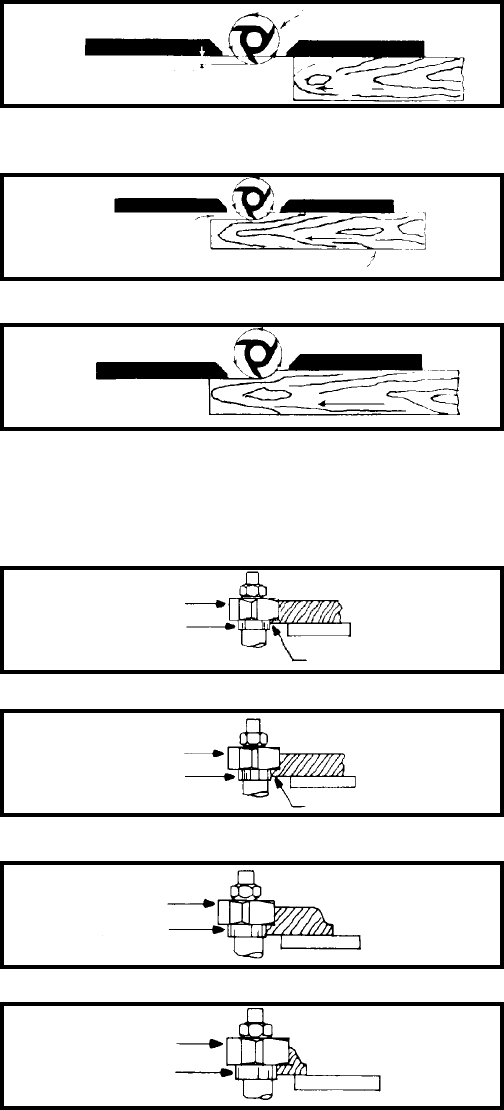

1. For average work, where a portion of the original

edge of the work is not touched by the cutter, both the

front and rear fences are in a straight line, as shown in

Fig. 36.

2. When the operation removes the entire edge of the

work, e.g., in jointing or making a full bead, the shaped

edge will not be supported by the rear fence when both

fences are in line, as shown in Fig. 37. In this case, the

work should be advanced to the position shown in Fig.

37 and stopped. Then turn the machine off.

3. The rear fence should then be advanced to contact

the work, as shown in Fig. 38. The rear fence will then be

in line with the cutting circle.

Fig. 36

Fig. 37

Fig. 38

ROUTING OR SHAPING WITH COLLARS AND STARTING PIN

When using collars and starting pin, the following rules must always be followed for good work and safety in operation.

Fig. 39

Fig. 40

1. Collars MUST be smooth and free of all gum or

other substances.

2. The edge of the work to be shaped MUST be

smooth, as any irregularity in the surface which rides

against the collar will be duplicated on the molded

surface.

3. A portion of the edge of the work MUST remain un-

touched by the cutters in order that the collar will have

sufficient bearing surface. Fig. 39, illustrates the wrong

way for the operation while Fig. 40 illustrates the right

way.

DEPTH OF CUT

CUTTING

CIRCLE

FEED

FRONT FENCE

REAR FENCE

NO SUPPORT

WORK

CUTTER

COLLAR

NOT SUFFICIENT

BEARING SURFACE

WRONG

CUTTER

COLLAR

SUFFICIENT

BEARING SURFACE

RIGHT

4. The work MUST be fairly heavy in proportion to the

cut being made as shown in Fig. 41. Under NO

circumstances should short work of light body be

shaped against the collars as shown in Fig. 42.

5. When shaping or routing with collars and starting

pin, the overhead guard, supplied with the machine,

should always be used.

Fig. 41

Fig. 42

RIGHT

CUTTER

COLLAR

WRONG

CUTTER

COLLAR