PAGE 4 SB-2-628-K

OPERATION

1. Mix, prepare and strain the material to be sprayed according to the

paint manufacturer’s instructions. Use a lint free mesh to strain the

material.

2. Turn on the cylinder air at source of supply. Supply air should be a

minimum of 50 PSI (3.5 bar). For consistant operation the pressure

should be regulated. If 50 psi (3.5 bar) cylinder air pressure is not

available, the red inner spring (31) can be removed. This allows a

minimum cylinder pressure of approximately 37 psi (2.6 bar).

Note

If the red inner spring (31) is removed, atomization pressure

should not exceed 70 psi (4.8 bar) (will result in gun not shutting

off).

3. Turn the needle adjustment knob (25) counterclockwise several turns.

With the cylinder air on, turn the adjustment knob (25) clockwise until

it contacts piston (19) (for maximum fluid flow). Back knob out 1/2 turn.

Note

Due to close part tolerances, actuate the gun on and off 7 or 8

times to "break-in" the packings. Do this with the material

supply off.

4. Adjust the atomization air pressure to 50 PSI (3.5 bars) or less. Aways

attempt to keep the pressure as low as possible to minimize overspray.

The fluid pressure should be between 10 to 15 PSI (0.7 to 1.0 bar).

5. Open the hand valve and/or trip the automatic valve if installed in the

system and observe the spray pattern. Adjust the air and fluid

pressures until the desired pattern is obtained. Control the fluid

pressure at the source of supply. If the desired regulation is not

practical at this point, restrict the flow by turning the adjustment knob

(25) clockwise.

Back Pressure – 46MP and 83MP "Maximum Performer"

Due to the unique cone shape of the MP fluid tips (nozzle), a slight back

pressure is created against the fluid column. This will reduce the amount

of fluid output. To compensate, increase the fluid regulator pressure

slightly if necessary. With 10 PSI (0.7 bar) cap pressure, back pressures are

approximately 3.5 PSI (0.24 bar) with the 46MP and 2.0 PSI (0.14 bar) with

the 83MP.

6. The width of the spray pattern is controlled by the adjusting valve (23)

marked “FAN” . With the “FAN” valve screwed fully clockwise, the

spreader air will be closed off causing a round pattern. By gradually

opening this valve, the pattern changes to a fan spray. The width is

determined by the amount the valve is opened. Atomization air is

adjusted by regulating the supply air to the gun.

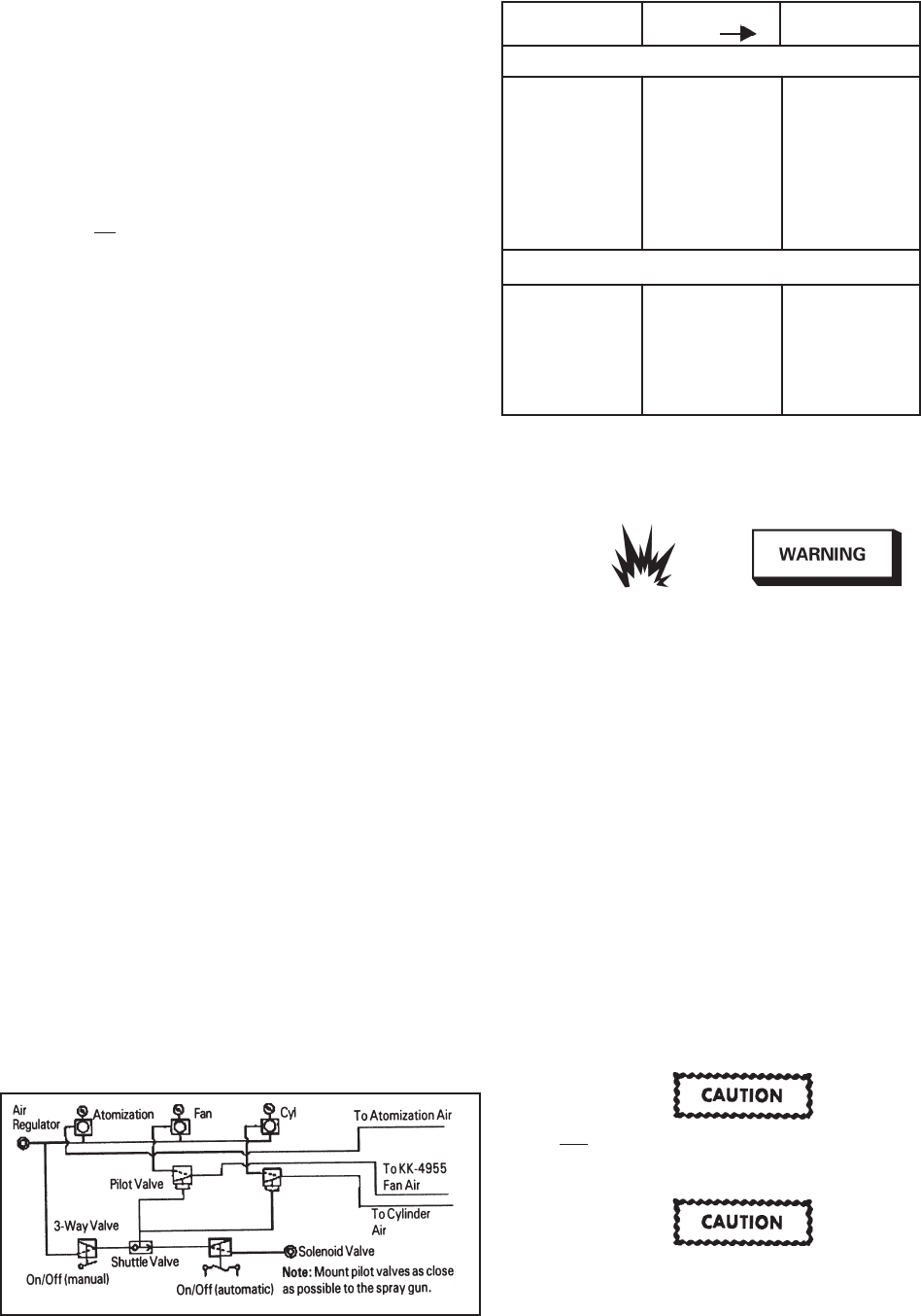

Adjustments to fan may be controlled remotely by using the optional

KK-4955 fan control adapter to replace the AGG-403 control valve (23).

A separate solenoid valve is required to control on/off function. See

Figure 2A.

7. Close the automatic valves and begin operation.

FIGURE 2A AIR CIRCUIT EXAMPLE WITH

OPTIONAL KK-4955 REMOTE FAN CONTROL

PREVENTIVE MAINTENANCE

Risk of Injury. Equipment and fluid may be under pressure.

Pressure in the system must be relieved before beginning

the cleaning procedure and before replacing any parts.

Follow the procedures in the literature provided with the

system.

Cleaning

1. Relieve air pressure from the pressure feed tank. Carefully

follow the instructions in the bulletin sent with the tank.

2. Replace material in the container with a suitable solvent.

3. Repressurize the system.

4. Trigger the gun and repeat the procedure until the gun and hose

are thoroughly clean (solvent is clean when it looks the same as

when you first opened solvent container). A SolventSaver™

type hose and gun cleaner which supplies a mixture of air and

solvent can be used to most effectiverly clean the gun and hose

internal passages. See "Accessories" on back page. Wipe the

exterior of the gun with a solvent dampened cloth.

5. If a recirculating system is used, it may be necessary to fit a shut

off valve in the return line to ensure the fluid tip and forward

portion of the sprayhead passage are properly cleaned when

flushed with solvent.

Do not totally submerge the gun in solvent. It is possible

to wash solids into the air operating sections of the gun

which could damage piston "O" ring seals.

The air cap can be immersed in solvent for cleaning. If the

orifices are clogged, use a broom straw or toothpick to

remove the obstruction. Never use a steel wire or hard

instrument. This will damage the air cap and result in a

distorted spray pattern.

If this No. on Tip Fluid Tip &

Tip Size ORDER Needle Set

400 Gr. Stainless Steel

In mm

E .070" 1.8 AV-2115-E AGX-4402-E

FF .055" 1.4 AV-2115-FF AGX-4402-FF

FX .042" 1.1 AV-2115-FX AGX-4402-FX

G .028" 0.8 AV-2115-G AGX-4402-G

FF .055" 1.4 AV-2120-FF AGX-4600-FF*

FX .042" 1.1 AV-2120-FX AGX-4600-FX*

D .086" 2.2 AV-2120-D AGX-4483-D**

E .070" 1.8 AV-2120-E AGX-4483-E**

303 Gr. Stainless Steel, U.H.M.W. Poly.

E .070" 1.8 AV-4915-E AGX-4300-E

FF .055" 1.4 AV-4915-FF AGX-4300-FF

FX .042" 1.1 AV-4915-FX AGX-4300-FX

FF .055" 1.4 AV-4920-FF AGX-4613-FF*

FX .042" 1.1 AV-4920-FX AGX-4613-FX*

E .070" 1.8 AV-4920-E AGX-4613-E

D .086" 2.2 AV-4920-D AGX-4613-D

* For use with 46MP air cap.

** For use with 83MP air cap.

CHART 3 FLUID TIPS (NOZZLE) AND NEEDLES