13

4. Raise the blade tension lever to the “up” position

and turn it clockwise to increase tension or counter-

clockwise to relieve the tension.

5. After the first turn, lower the blade tension lever and

check the tension scale. If the tension is still not

correct, repeat the procedure.

The tension scale is correct for standard blades

used on average work. Although you may rely on the

feel or tone of the blade, Delta recommends that

you use the tension scale to avoid blade breakage

by applying too much or too little tension.

NOTE: When the machine is not in use, relax the

tension on the blade by lifting the blade tension lever

to the “UP” position. Remember to lower the

blade tension lever before using the machine

again.

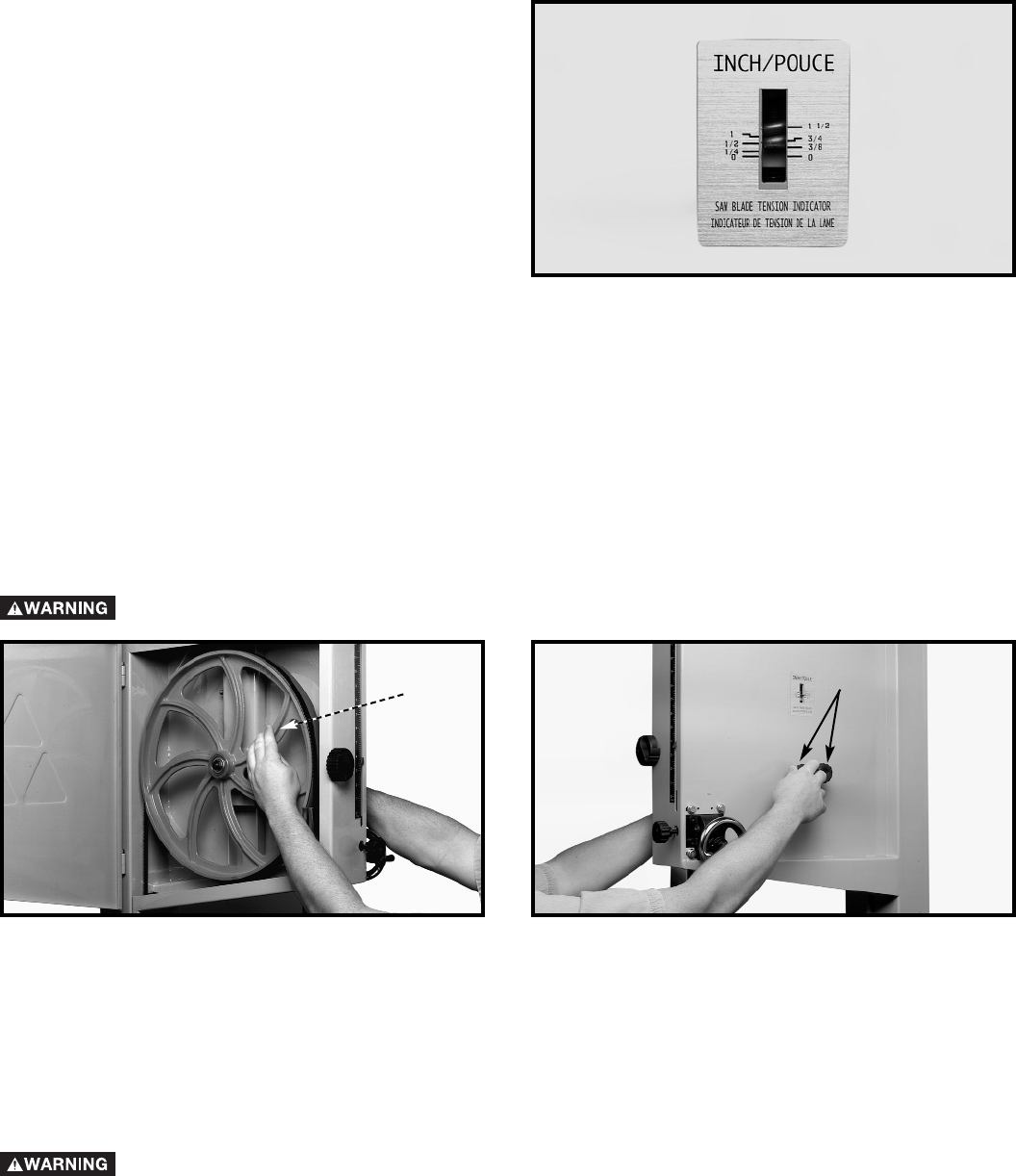

Fig. 18

TRACKING THE BLADE

For accurate work and maximum blade life, center the blade on the upper wheel. With proper tracking adjustment, the

blade will run steadily in the same line. Before adjusting the tracking, move the upper and lower blade guides and blade

support bearings away from the sides and back of the blade (See “ADJUSTING UPPER BLADE GUIDES AND BLADE

SUPPORT BEARING” and “ADJUSTING LOWER BLADE GUIDES AND BLADE SUPPORT BEARING” in this

manual. Also, tension the blade properly by following the instructions under “ADJUSTING BLADE TENSION”.

DISCONNECT MACHINE FROM POWER SOURCE.

Fig. 19

To adjust:

1. Rotate the upper wheel (A) Fig. 19 forward by hand and turn the tracking adjustment hand knobs (B) Fig. 20 until

the blade travels in the center of the upper wheel’s tire. Be sure the knobs (B) Fig. 20 are always turned equal

amounts.

NOTE: Before turning the hand knobs (B) Fig. 20, loosen the locknuts located under the knobs.

2. Connect the machine to the power source and turn the switch “ON” and “OFF” to be certain that proper tracking

is maintained.

To avoid possible injury and/or damage to the blade, do not make the initial tracking adjustment

while the machine is under power. The blade may run off the wheel instantly at high speed.

Adjust the tracking knobs (B) Fig. 20 only a fraction of a turn at a time. Each blade has its own

tendencies, especially after welding or brazing. Repeat the blade tracking adjustment each time

a new or repaired blade is installed, regardless of prior adjustments.

Fig. 20

3. Make any necessary final adjustments at operating speed and tighten the locknuts located under the knobs (B)

Fig. 20.

A

B