10

WARNING: To reduce the risk of

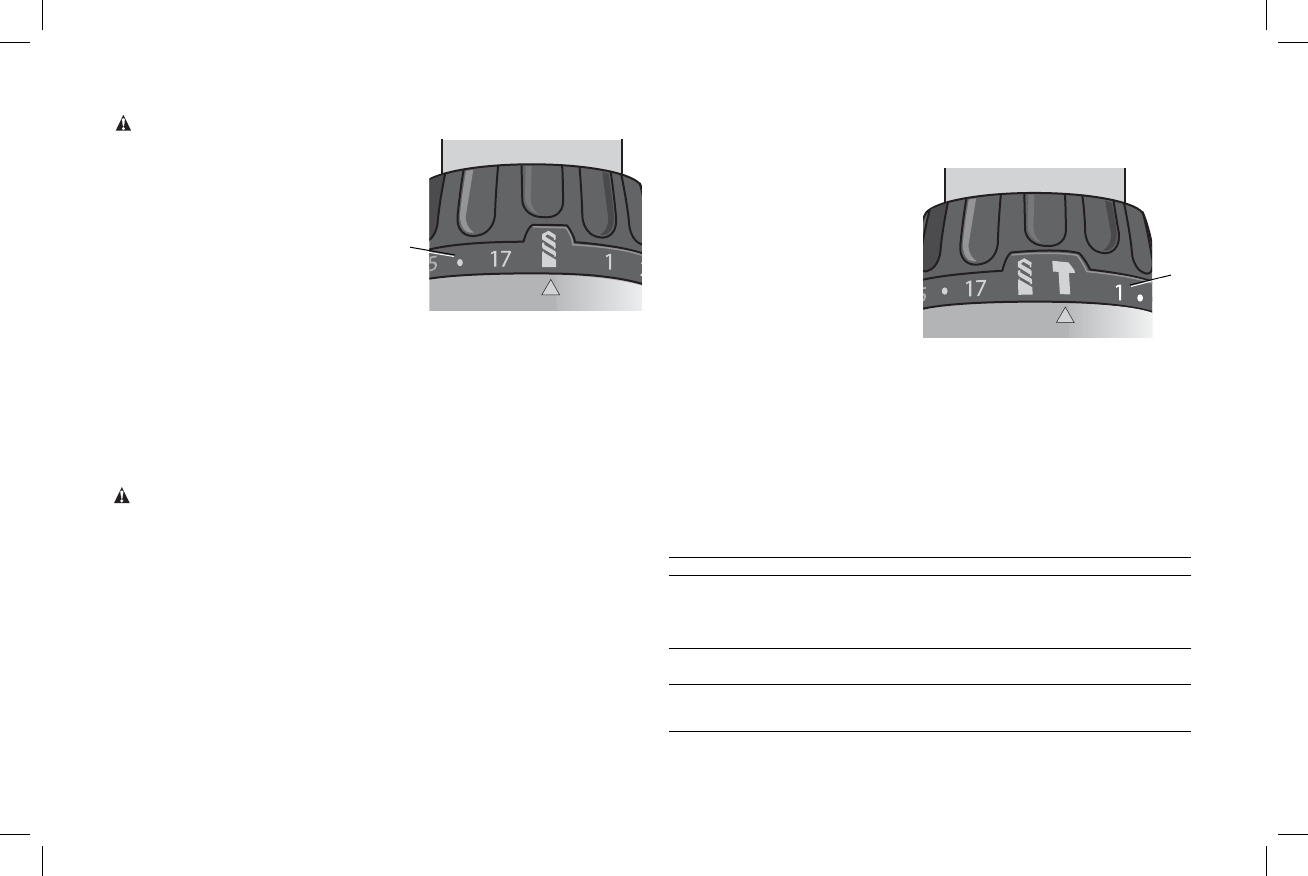

FIG. 4

DRILLING

C

personal injury, ALWAYS ensure

workpiece is anchored or clamped firmly.

If drilling thin material, use a wood

“back-up” block to prevent damage to

the material.

1. Use sharp drill bits only. For WOOD,

use the low speed setting and twist

drill bits, spade bits, power auger

bits, or hole saws. For METAL, use

the low speed setting and steel

twist drill bits or hole saws. For

MASONRY, such as brick, cement,

cinder block, etc., use carbide-tipped bits rated for percussion drilling. Use low

speed for bits greater than 10 mm (3/8").

2. Always apply pressure in a straight line with the bit. Use enough pressure to keep

drill biting, but do not push hard enough to stall the motor or deflect the bit.

3. Hold tool firmly with both hands to control the twisting action of the drill. If model

is not equipped with side handle, grip drill with one hand on the handle and one hand

on the battery pack.

CAUTION: Drill may stall if overloaded causing a sudden twist. Always expect the

stall. Grip the drill firmly to control the twisting action and avoid injury.

4. IF DRILL STALLS, it is usually because it is being overloaded or improperly used.

RELEASE TRIGGER IMMEDIATELY, remove drill bit from work, and determine

cause of stalling. DO NOT CLICK TRIGGER ON AND OFF IN AN ATTEMPT TO

START A STALLED DRILL — THIS CAN DAMAGE THE DRILL.

5. To minimize stalling or breaking through the material, reduce pressure on drill and

ease the bit through the last fractional part of the hole.

6. Keep the motor running when pulling the bit back out of a drilled hole. This will

help prevent jamming.

7. With variable speed drills there is no need to center punch the point to be drilled.

Use a slow speed to start the hole and accelerate by squeezing the trigger harder

when the hole is deep enough to drill without the bit skipping out.

Hammerdrill Operation (Fig. 5)

1. Turn the collar (C) to the

HAMMERDRILLING

FIG. 5

C

hammerdrill symbol.

2. Select the high speed setting by

sliding the selector back (away

from the chuck).

IMPORTANT: Use carbide-tipped

or masonry bits only.

3. Drill with just enough force on the

hammer to keep it from bouncing

excessively or "rising" off the bit.

Too much force will cause slower

drilling speeds, overheating and

lower drilling rate.

4. Drill straight, keeping the bit at a right angle to the work. Do not exert side

pressure on the bit when drillling as this will cause clogging of the bit flutes and a

slower drilling speed.

5. When drilling deep holes, if the hammer speed starts to drop off, pull the bit

partially out of the hole with tool still running to help clear debris from the hole.

NOTE: A smooth, even flow of dust from the hole indicates proper drilling rate.

MAXIMUM RECOMMENDED CAPACITIES

DC725-XE, DCD775-XE,

DC727-XE, DC737-XE

DC720 DC730, DC743

Size Speed Size Speed Size Speed

WOOD

Auger 22 mm (7/8") 1 22 mm (7/8") 1 10 mm (3/8") 1

Paddle 25 mm (1") 2 25 mm (1") 2 38 mm (1") 2

Twist 13 mm (1/2") 1–2 13 mm (1/2") 1–2 10 mm (3/8") 1–2

METAL

Twist 13 mm (1/2") 1–2 13 mm (1/2") 1–2 10 mm (3/8") 1–2

MASONRY

Carbide 6.35 mm (1/4") 2 – – – –