7

English

A

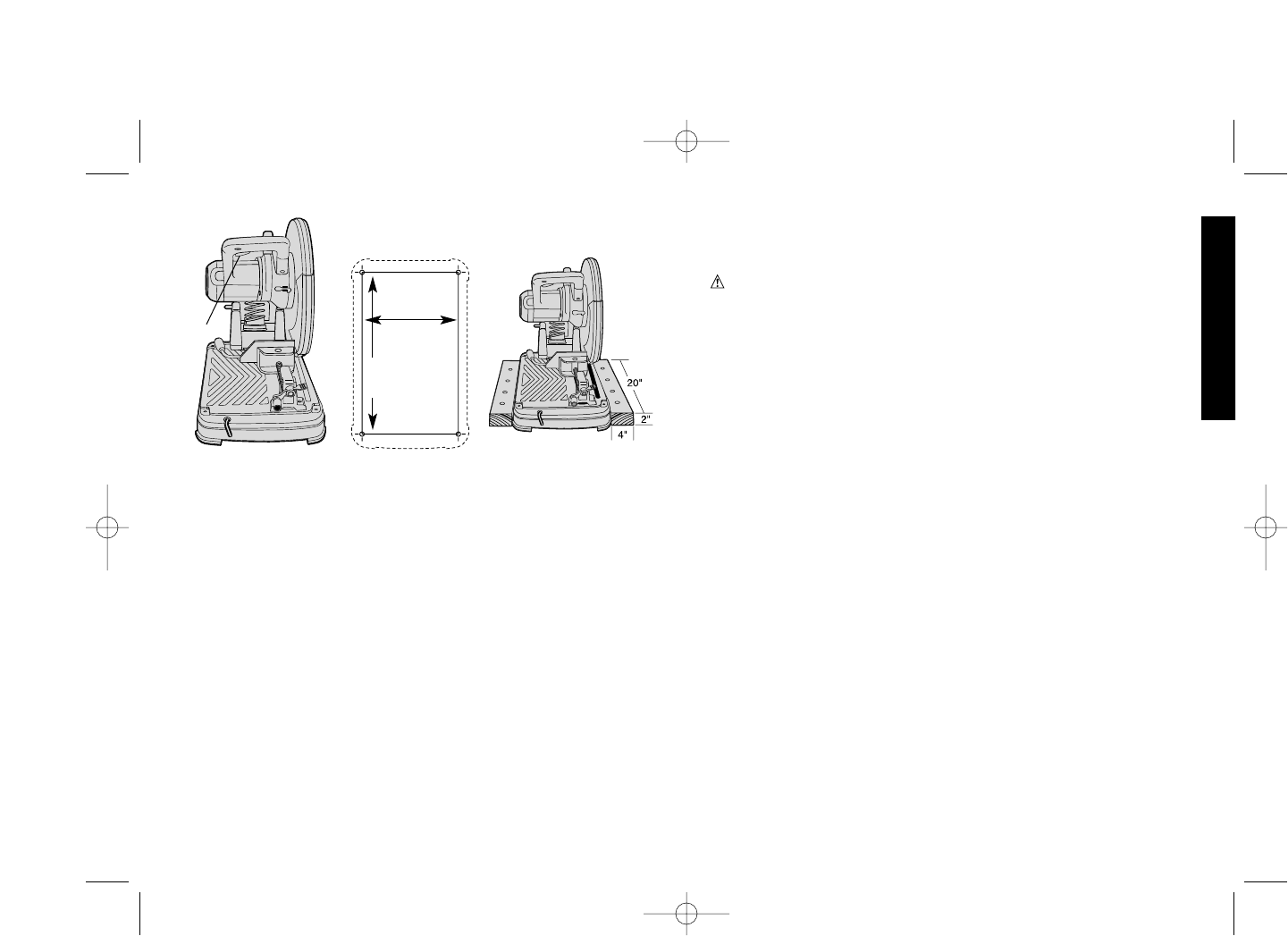

FIG. 13

FIG. 14

10-1/8"

(257 MM)

FIG. 15

17-3/8"

(441 MM)

blade extends into the base.

3. Place a square (C) against the blade (D), adjust the fence against

the square and then re-lock the fence.

4. Unlock and raise the arm.

5. Loosen the two angle plate screws (E). Align the 0˚ pointer with

the edge of the slot (B) and retighten the screws.

Chip Deflector Adjustment (Fig. 8)

To aim chips away from surrounding area or into a collection bin,

loosen the screw (A), adjust the chip deflector (B) angle and retighten

the screw.

Auxiliary Vertical Clamp (Fig. 9)

The auxiliary vertical clamp (A) MUST be used with the vise when

cutting wide or irregular shaped materials, when making angle cuts,

and when the fence is in the rear positions where the upstroke of the

blade tends to pull the workpiece up from the vise.

To use the clamp, insert it in one of the holes (Fig. 11,G) in the base

until the clamp rests on the workpiece. Press the lever down as

shown in Fig. 9 to lock the workpiece in place. Lift the lever to release

the clamp.

NOTE: When clamping thin stock, a shim of suitable thickness may

be required under the clamp pad.

WARNING: Failure to use vertical clamping when cutting on the

upstroke of the blade may result in serious damage to the tool and

possible personal injury.

Material Positioning and Clamping Tips

(Fig. 10, 11, 12)

• TURN OFF AND UNPLUG TOOL BEFORE MAKING ANY

ADJUSTMENT TO THE SAW OR REPOSITIONING A WORK-

PIECE.

• In general, position the workpiece so it will be cut on the down-

stroke of the blade. (Shaded area) Slot (A) indicates the best fence

position for general cutting at 90˚.

• Slots (A) and (B) indicate the best fence positions for general

cutting at 90˚ and 45˚. Slots (C) and (D) indicate the same for larger

pieces. (Fig. 11)

• When the fence is lined up with a slot in the base, the spring loaded

pin (E) will drop into the corresponding hole (F) in the base to

further secure the fence position. To move fence to another

position, pull up the pin.

• The fence can also be used in other angles and positions, as

needed.

• Long workpieces must be supported by a block so it will be level

with the saw table The cut off piece should be free to fall downward

to avoid blade binding.(Fig. 12)

• ALWAYS CLAMP THE WORKPIECE SECURELY, NO EXCEP-

TIONS.

• Always clamp the workpiece with the vise and auxiliary vertical

clamp as described.

• The auxiliary vertical clamp or other clamping aids such as spring,

bar or C-clamps will compliment the vise for holding certain sizes

and shapes of work pieces. Use care in selecting and placing these

392736-01,00,DW872 6/29/00 9:00 AM Page 7