English

14

making any adjustments or removing/installing attachments

or accessories.

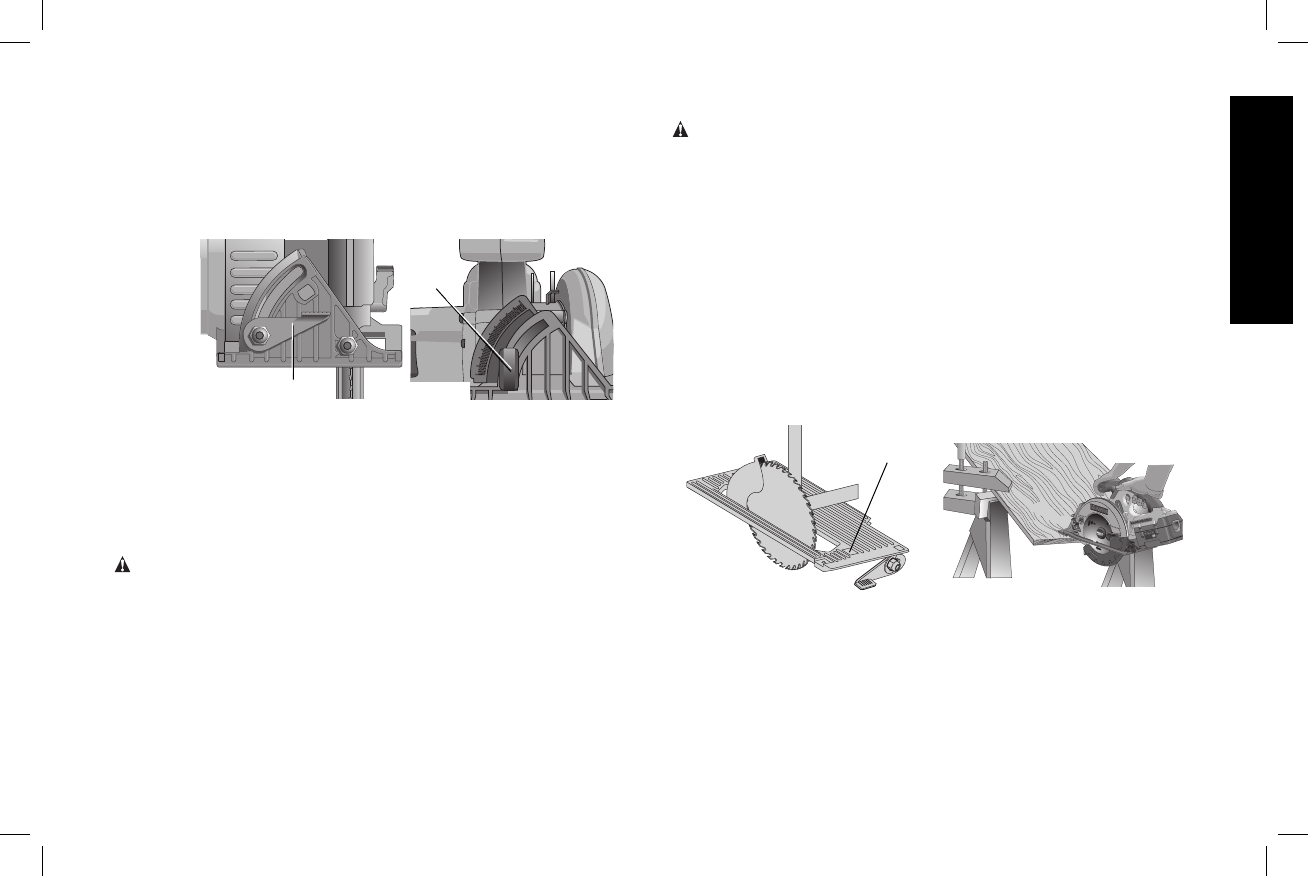

The full range of the bevel adjustment is from 0˚ to 50˚.

The pivot bracket is graduated in increments of 1˚. On the

front of the saw is a bevel angle adjustment mechanism

(Fig. 11) consisting of a calibrated pivot bracket and a bevel

adjustment lever (DC300) or knob (DC310).

J

DC300

J

DC310

FIG. 11

TO SET THE SAW FOR A BEVEL CUT (FIG.11)

1. Raise the lever or knob (J) to loosen the bevel adjustment and

tilt shoe to the desired angle by aligning the pointer with the

desired angle mark.

2. Retighten the bevel adjustment by lowering the lever.

Bevel Detent (DC300 only)

WARNING: To reduce the risk of serious personal injury,

turn tool off and disconnect tool from battery pack before

making any adjustments or removing/installing attachments

or accessories.

The saw is equipped with a bevel detent feature. As you tilt the

shoe you will hear a click and feel the shoe stop at both 22.5 and

45 degrees. If either of these is the desired angle, retighten the

lever (J) by lowering it. If you desire another angle, continue tilting

the shoe until the pointer aligns with the desired mark. Retighten

lever (J) by lowering it.

Shoe Adjustment for 90˚ Cuts

WARNING: To reduce the risk of serious personal injury,

turn tool off and disconnect tool from battery pack before

making any adjustments or removing/installing attachments

or accessories.

IF ADDITIONAL ADJUSTMENT IS NEEDED (FIG. 12)

1. Adjust the saw to 0˚ bevel.

2. Retract blade guard. Place the saw on blade side.

3. Loosen bevel adjustment lever or knob (J). Place a square

against the blade and shoe to adjust the 90˚ setting.

4. Turn the adjustment screw (K) on the underside of the shoe

until the blade and the shoe are both in flush contact with the

square. Retighten the bevel adjust lever or knob.

5. Confirm the accuracy of the setting by checking the squareness

of an actual cut on a scrap piece of material.

FIG. 12

K

FIG. 13

Kerf Indicator

The front of the saw shoe has a kerf indicator for vertical and bevel

cutting. This indicator enables you to guide the saw along cutting

lines penciled on the material being cut. The indicator lines up

with the left (outer) side of the saw blade, which makes the slot or

“kerf” cut by the moving blade fall to the right of the indicator. Guide

along the penciled cutting line so that the kerf falls into the waste

or surplus material.