11

Accessories can be damaged during handling,

and can fly apart as they come up to speed.

This is not common, but it does happen.

Practice on scrap materials first to see how the

Rotary Tool's high speed action performs.

Keep in mind that the work is done by the

speed of the tool and by the accessory in the

collet. You should not lean on or push the tool

during use.

Instead, lower the spinning accessory lightly to

the work and allow it to touch the point at

which you want cutting (or sanding or etching,

etc.) to begin. Con centrate on guiding the tool

over the work using very little pressure from

your hand. Allow the accessory to do the work.

Usually, it is best to make a series of passes

with the tool rather than attempt to do all the

work in one pass. To make a cut, for example,

pass the tool back and forth over the work,

much as you would a small paint brush. Cut a

little material on each pass until you reach the

desired depth. For most work, the gentle touch

is best. With it, you have the best control, are

less likely to make errors, and will get the most

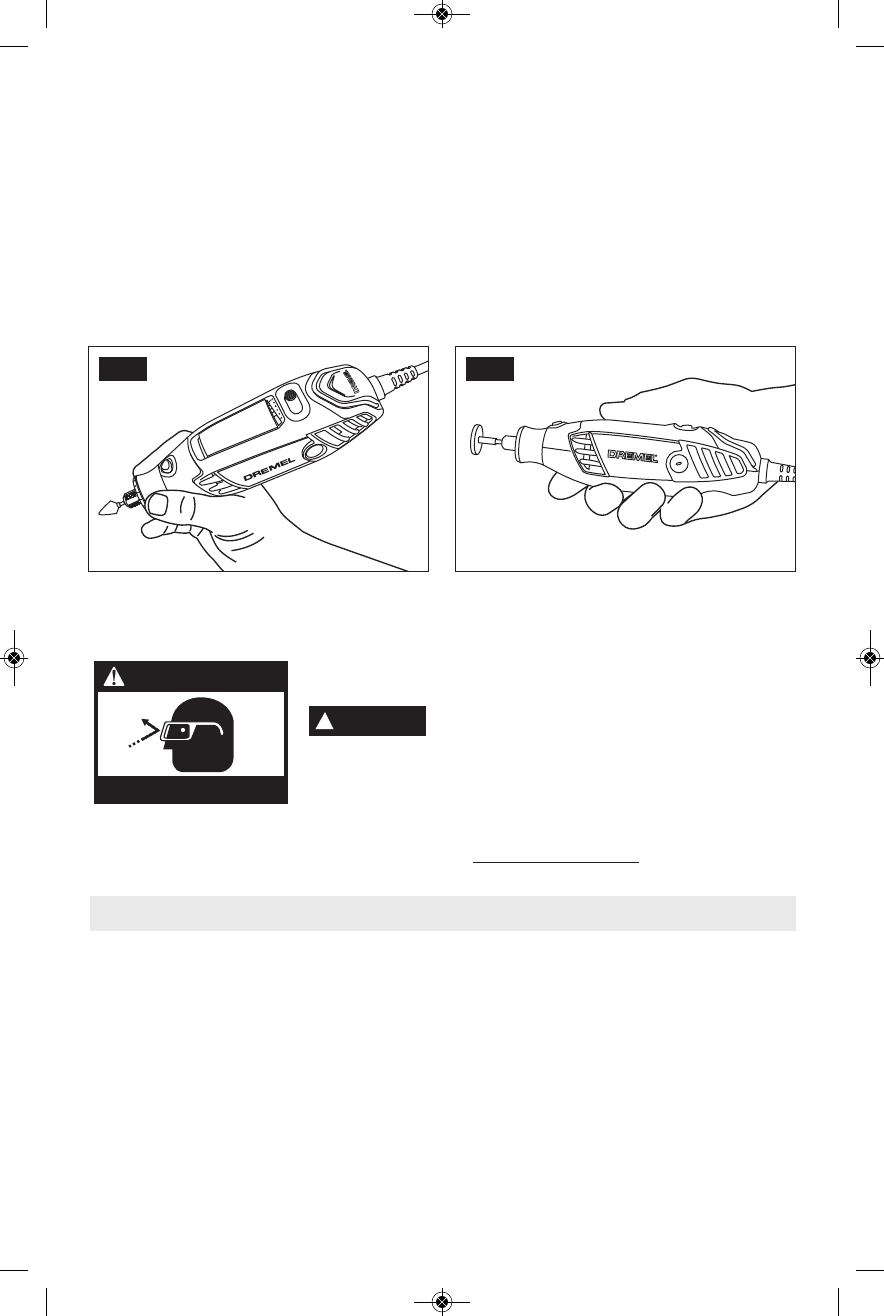

For best control in close work, grip the

Rotary Tool like a pencil between your

thumb and forefinger.

The “Golf Grip” method of holding the tool

is used for more aggressive operations

such as grinding a flat surface or using

cutoff wheels.

FIG. A FIG. B

WARNING

Wear Eye Protection

Whenever you hold the tool, be careful not to

cover the air vents with your hand. This

blocks the air flow and causes the motor to overheat.

CAUTION

!

Questions or Problems? Call 1-800-437-3635

or check our website at www.Dremel.com

Operating Speeds

To select the right speed for each job, use a

practice piece of material.

NOTE: Speed is affected by voltage

changes. A reduced incoming voltage will

slow the RPM of the tool.

(MODEL 100)

On the single speed model, there is an ON-

OFF switch. When the switch is on, the tool

runs at 35,000 RPM.

(MODEL 200)

On the two-speed model, there is a LO and HI

switch. When the switch indicator is on the low

setting, the tool runs at about 15,000 RPM.

When the switch indicator is on the high

setting, the tool runs at about 35,000 RPM.

(MODEL 3000)

On the vari able speed model, there are

switch setting in dicators marked with a line.

Slide to the number on the housing to select

the operating speed needed from 5,000 –

32,000 RPM. You can refer to the charts

on page 19, 20, 21 and 22 to determine the

proper speed, based on the materi al being

worked and the type of accessory being

used. These charts enable you to select

DM 2610015339 05-11:DM 2610015339 05-11.qxp 5/12/11 9:40 AM Page 11