10

Saw Table Tilt

- For bevel cuts the table can be tilted up to 45°. Loosen

the wing nut (135) of the table trunnion assembly, tilt

the table to the required position and retighten the wing

nut. Make trial cut in a piece of scrap wood to verify

setting to desired angle.

- Hand guards:

Prior to tilting the two hand guards on the underside of

the table must be moved towards the fence guide

extrusion to clear the blade when the table is tilted.

7 Additional Information

For this band saw a range of optional accessories is

available. Both the band saw and the accessories are

only to be used for operations as described in this

manual or in the instructions supplied with the

accessories. Please contact your supplier or local agent

if you require additional technical information.

6 Safety Rules

1. Always disconnect from power when changing blades

or servicing the machine.

2. Before switching machine on be sure that all guards

are in place and securely locked.

3. Do not use cracked or bent saw blades.

4. Replace table inserts (24/79) if slot has enlarged.

5. For cutting operations with tilted table the rip fence

must be placed to the right of the blade.

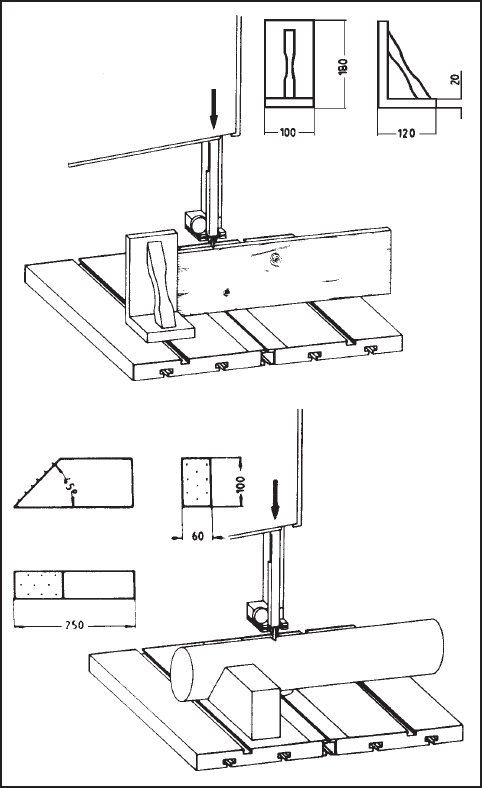

6. When cutting round stock use a suitable jig to prevent

the work from turning.

7. When cutting boards in an upright position use a

suitable push block to prevent kickback.

8. Before tilting the table for bevel cuts replace the table

insert (79) with the wide slot table insert (24).

9. For safe operation and to keep dust emission within

the legal limits a dust collector with a minimum air flow

rate of 20 m/s must be connected to this band saw.

9 Optional Accessories

Circular Cutting Attachment

Stock-no. 090 903 1249

For cutting radii from 30 to 260 mm.

Belt Sanding Attachment

Stock-no. 090 903 1087

Quick and simple adaption of the belt sanding attachment

to the saw. For finishing the cut edge or deburring.

Because of the many different plastics available the

proper sanding belt speed must be found by testing.

Wheel Set

Stock-no. 090 900 0505

Fitting the wheel set to the machine makes the saw

mobile.

Precision Blade Guide

Stock-no. 090 901 0896

- Higher precision and better performance of the saw.

- TCT guide bearing for longer service life.

- Requires no tools for setting and replacing the guide

and thrust bearings.

8 Connection to Power Mains

Damaged power cables must be replaced immediately

by a qualified electrician. Risk of electric shock if

operated with a damaged power cable.

Children and juveniles should not to operate this machine.

This band saw is equipped with a 1.1 kW 230 V single-

phase motor. For connection to power mains the power

cable is fitted with an earthed plug.

All models are equipped with an electronic brake. A light

humming sound emitted from the switch for a short

period after connection to power is normal and does not

indicate a fault. If the brake fails have the fine-wire fuse

inside the switch checked. The max. permissible number

of 20 switching actuations per hour should not be

exceeded.

The electrical installation must ensure that a dust collector

starts up when this band saw is switched on (e.g. with an

induction coil in the supply lines).