11

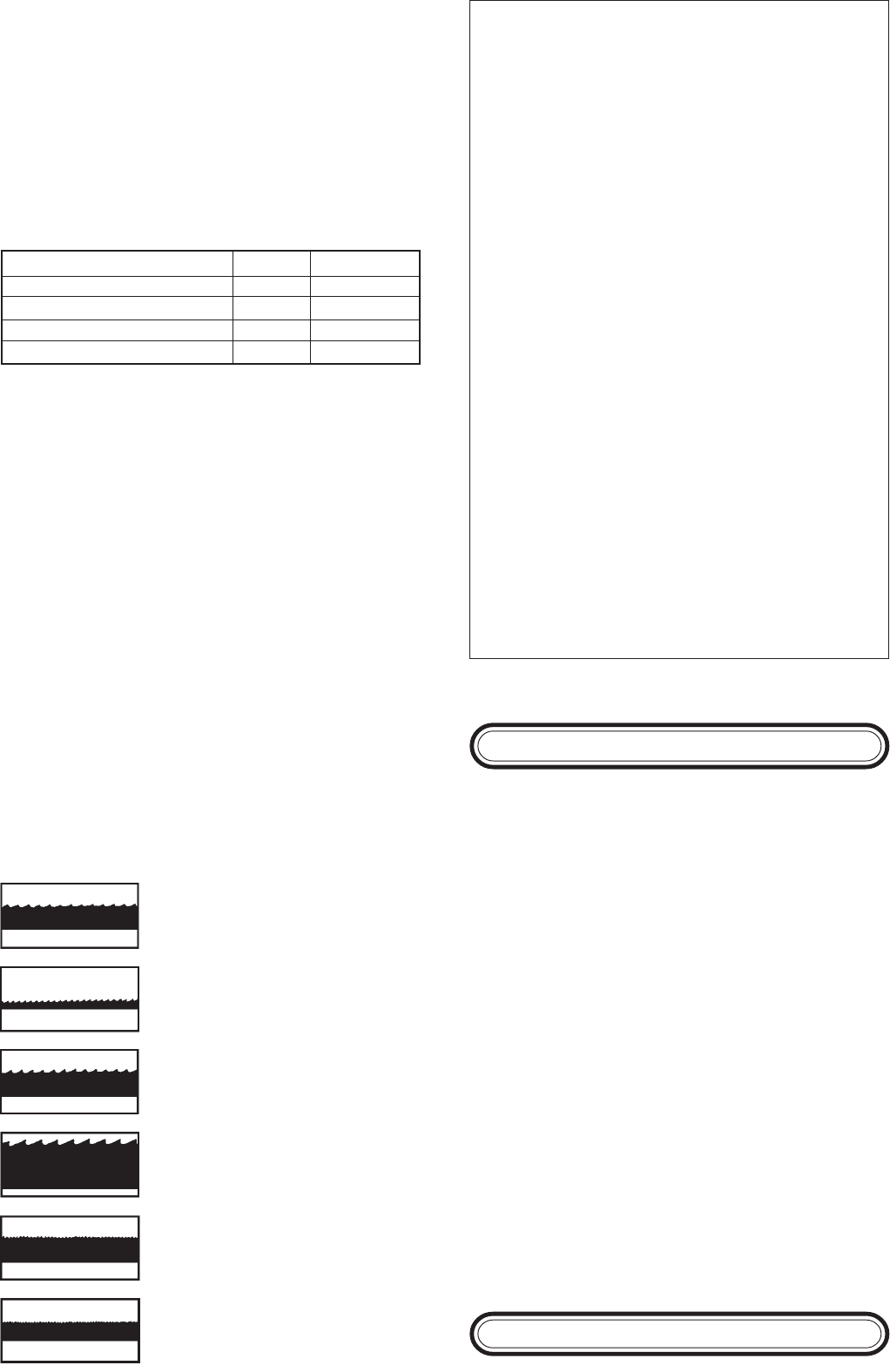

Blade for NF-metals

3380x15x0.5 mm

tooth spacing A 2 mm

Stock-no. 090 902 9210

Blade for carbon steel

3380x13x0.65 mm

tooth spacing 14 teeth/inch

Stock-no. 090 902 9229

Blade for cutting fire wood

3380x25x0.6 mm

tooth spacing A 8 mm

Stock-no. 090 900 0424

General purpose blade for straight and

contour cuts, 3380x15x0.5 mm

tooth spacing A 6 mm

Stock-no. 090 902 9171

Blade for wood contour cuts

3380x6x0.5 mm

tooth spacing A 4 mm

Stock-no. 090 902 9180

Blade for straight cuts

3380x25x0.6 mm

tooth spacing A 4 mm

Stock-no. 090 900 0416

11 Replacement Saw Blades

Standard delivery: blade with induction-hardened teeth

for a longer tool life.

10 Dust collection

Caution! Dust of certain wood spezies is carcinogenic.

➜ When operating your woodworking machine indoors

connect to a dust collector.

➜ If a woodworking machine is operated indoors for

more than 30 minutes, it is mandatory to connect it to a

dust collector.

Important information to consider when choosing a dust

collector:

Please note:

- The airflow at the suction port (of the woodworking

machine) should not be less than 20 m/s.

Check with your dealer on the different dust collectors

available from Elektra Beckum.

Unit Min. value

Port diameter mm 100

Mean air speed m/s 20

Vacuum Pa 1640

Volume flow rate m

3

/h 565

Caution! With extented daily use of your woodworking

machine an automatic start/stop device, which

automatically switches the dust collector on and off when

the woodworking machine is started/stopped, is required.

This automatic power relay is available in two different

versions from Elektra Beckum:

- Automatic Power Relay ALV 1 1~230 V

stock-no. 091 301 4626

12 U.K. Supplement to Operating

Instructions for Elektra Beckum Band

Saw BAS 500

Please note the following supplementary information

associated with this machine:

U.K. Legislation and Codes of Practice

When used industrially within the U.K. this machine

falls under the scope of

● Woodworking Machines Regulations 1974

and

● Use and Provisions of Work Equipment

Regulations 1992

We strongly advise you study and follow these

regulations.

Section 5.0 - Connection to Power Mains

230 V motor. Although the motors supplied with this

machine will run safely on a 13 A domestic ring main,

on starting the machine a high current of very short

duration is drawn, which could cause your 13 A fuse

to blow. If this persists we recommend to have the

machine connected to a 16 A separate radial circuit

using BS 4343 (CEE 17) plug and socket. Ensure the

installation is protected by a suitable fuse or miniature

circuit breaker.

This work should be undertaken only by a qualified

electrician!

Warning: This appliance must be earthed!

Wiring Instructions

If the plug, fitted to the power cable supplied with the

machine, has to be changed or replaced, connect the

mains lead conductors in accordance with the following

colour code.

Single-phase motors (110/115/220/230/240 volts):

Yellow/green - Earth

Blue - Neutral

Brown - Live

Three-phase motors (220/380/400/415/440 volts):

Machines with a 3-phase motor are connected to power

mains using a 5-pin industrial appliance-inlet/connector

according to VDE 0623/BS 4343/IEC 309.

4-wire mains lead Yellow/green - Earth

Brown - Phase (L1)

Black - Phase (L2)

Blue - Phase (L3)

5-wire mains lead Yellow/green - Earth

Brown - Phase (L1)

Black - Phase (L2)

Black - Phase (L3)

Blue - Neutral

IF IN DOUBT - CONSULT A QUALIFIED ELECTRICIAN!