22

ENGLISH

8.1 Sawing

1. Choose and install a table insert

extrusion suitable for the type of cut

to be performed:

− table insert extrusion with a nar-

row slot for standard cross cuts

only;

− table insert extrusion with bevel-

led slot for bevel cuts also.

2. Adjust the band saw blade speed.

3. If necessary, adjust the table tilt.

4. Select rip fence and table tilt for the

type of cutting operation to be car-

ried out.

5. Set upper blade guide 3 mm above

the workpiece.

3

Note:

Always make a trial cut in a piece

of scrap to verify settings; correct if nec-

essary before cutting the workpiece.

6. Place workpiece on the saw table.

7. Plug in.

8. Start saw.

9. Cut workpiece in a single pass.

10. Switch off if no further cutting is to

be done immediately afterwards.

A

Danger!

Prior to all servicing:

− switch machine OFF.

− wait until the saw has come to a

complete stop.

− unplug power cable.

• Check that all safety devices are

operational again after each service.

• Replace defective parts, especially

of safety devices, only with genuine

replacement parts. Parts not tested

and approved by the equipment

manufacturer can cause unforeseen

damage.

• Repair and maintenance work other

than described in this section should

only be carried out by qualified spe-

cialists.

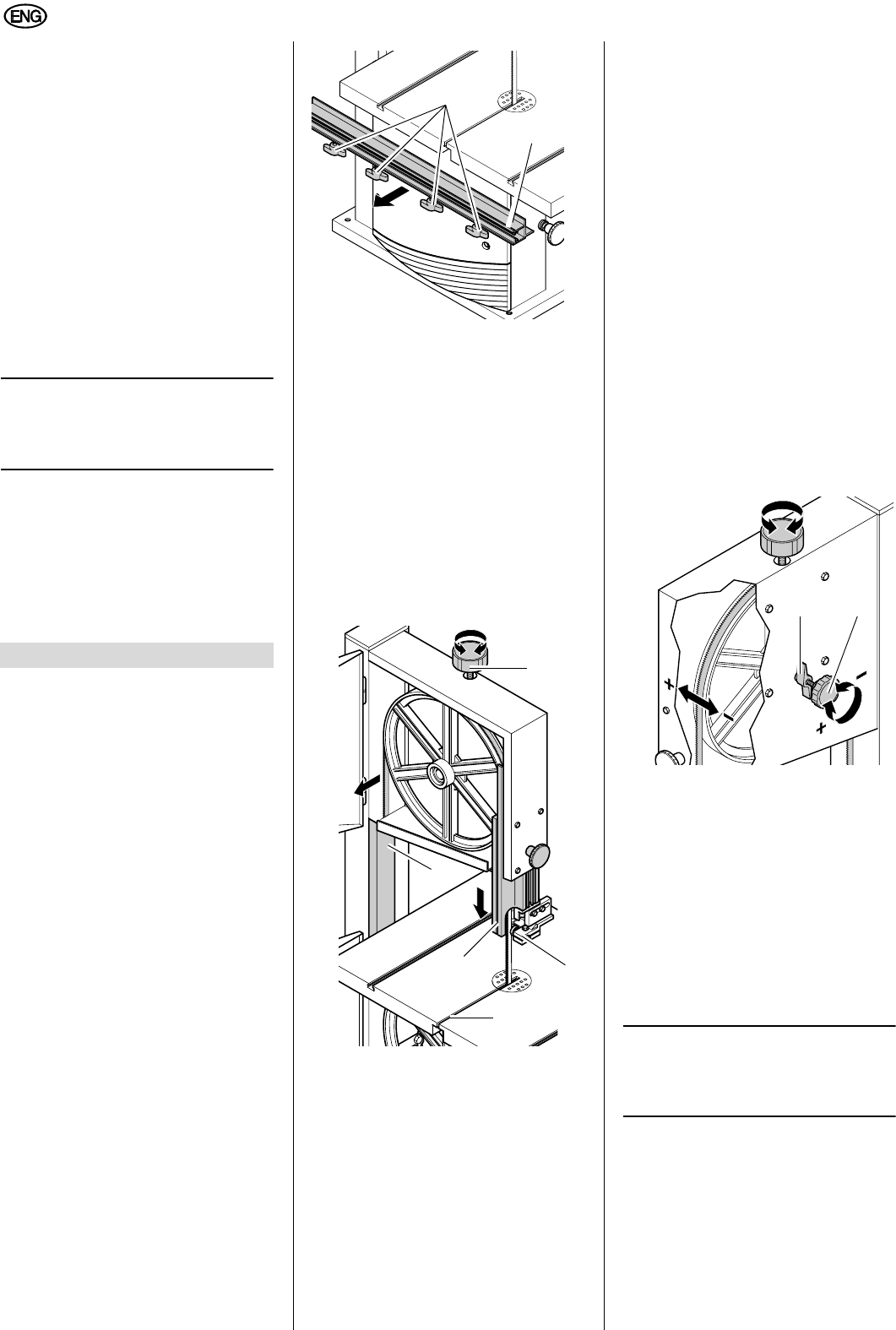

9.1 Band saw blade change

A

Danger!

Risk of injury, even with the

band saw blade at standstill. Wear

gloves when changing blades. Use

only suitable band saw blades (see

“Technical specifications”).

1. Loosen the four thumb screws (50)

and remove the fence guide extru-

sion (51).

2. Open both housing doors.

3. Adjust upper blade guide (52) to its

lowest position.

4. Loosen setting knob (53) until the

band saw blade has slackened.

5. To remove the band saw blade,

guide it through

− the slot in the saw table (54),

− the blade guard on the upper

blade guide (55),

− the blade cover on the saw hous-

ing (56) and

− the blade guides.

6. Fit fresh band saw blade. Observe

correct position: the teeth point

towards the front (door) side of the

saw.

7. Center band saw blade on the rub-

ber tyres of the band saw wheels.

8. Tighten setting knob until blade

does no longer slip off the band saw

wheels.

9. Close both housing doors.

10. Then:

− tension band saw blade (see “Ini-

tial operation”).

− align band saw blade (see “Care

and maintenance”);

− align blade guides (see “Care

and maintenance”);

− let saw test run for at least one

minute;

− stop saw, unplug and recheck

settings.

9.2 Band saw blade align-

ment

If the band saw blade does not run in the

centre of the rubber tyres, the tracking

needs to be corrected by adjusting the

tilt of the upper band saw wheel:

1. Loosen locking nut (57).

2. Turn setting knob (58):

− Turn setting knob (58) clockwise

if the band saw blade runs

towards the front of the saw.

− Turn setting knob (58) counter-

clockwise if the band saw blade

runs towards the rear of the saw.

3. Tighten locking nut (57).

9.3 Upper blade guide align-

ment

The upper blade guide consists of:

− a large thrust bearing (supports the

band saw blade from the rear),

− two smaller guide bearings (provid-

ing lateral support).

All bearings need to be readjusted after

every band saw blade change and/or

tracking.

3

Note:

Periodically check the guide

bearings for wear, if necessary replace

both guide bearings at the same time.

1. Turn the ratchet lock lever (59) to

loosen the thrust bearing (60), so it

will easily move in the direction of

arrows.

9. Care and Maintenance

50

51

52

53

54

55

56

57 58