9

DH 315

Machine transportation

1. Fold both infeed and outfeed table up.

2. Wind power cable around cable holder on the

machine's side.

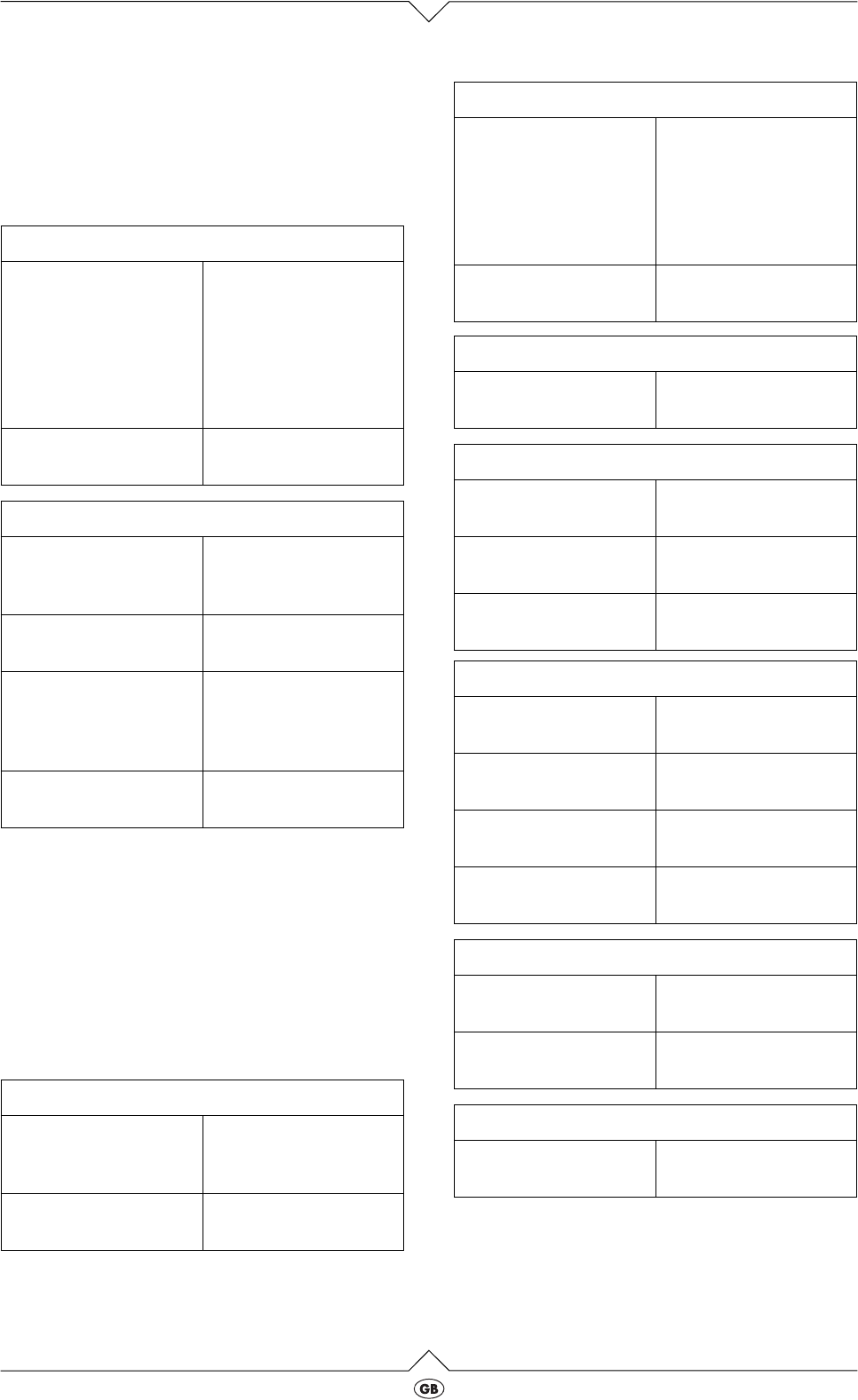

Service plan

Troubleshooting

A

Danger!

Before carrying out any fault service or

maintenance work always:

- Switch machine OFF.

- Unplug power cable.

- Wait until cutterblock is at standstill.

Check that all safety devices are operational again

after each service.

Prior to operation

- Inside of machine

- Threaded spindles of

rise and fall mecha-

nism

- Dust spout (when

working without dust

collection)

Remove chips and

dust

Infeed and outfeed

table

Apply a thin coat of sli-

ding wax.

Monthly (if used daily)

Threaded spindles of

rise and fall mecha-

nism

Saw blade change

Alignment of infeed

and outfeed table

Check, adjust if neces-

sary

Power supply cable Check for damage, if

necessary have repla-

ced by a qualified elec-

trician.

Carbon brushes of

motor

Check, replace if

necessary

Motor does not run

No-voltage relay trip-

ped by a temporary

power failure.

Switch on again.

No supply voltage Check cables, plug,

outlet and mains fuse.

Motor overheated,

e.g. by

- dull cutter knives

- overloading

- chip build-up in the

cutterblock cover

Remove cause for

overheating, let cool

down for a few minu-

tes, then depress the

reset button and

restart the planer.

Carbon brushes worn Replace carbon brus-

hes.

Power wanes

Cutter knives dull Replace with fresh cut-

ter knives.

Planed surface too rough

Cutter knives dull Replace with fresh cut-

ter knives.

Cutter knives blocked

by chips

Remove chips.

Stock contains still too

much moisture

Dry workpiece.

Planed surface cracked

Cutter knives dull Replace with fresh cut-

ter knives.

Cutter knives blocked

by chips

Remove chips.

Workpiece was pla-

ned against the grain

PLane workpiece with

the grain.

Too much material

removed in one pass

Make several passes

with less chip removal.

Feed rate too little

Support surface for

workpiece fouled

Clean support sur-

faces and wax slightly.

In- and outfeed rollers

binding

Have feed rollers ser-

viced.

Workpiece jammed

Too much material

removed in one pass

Make several passes

with less chip removal.

Motor does not run