4

DH 315

Installation and connection

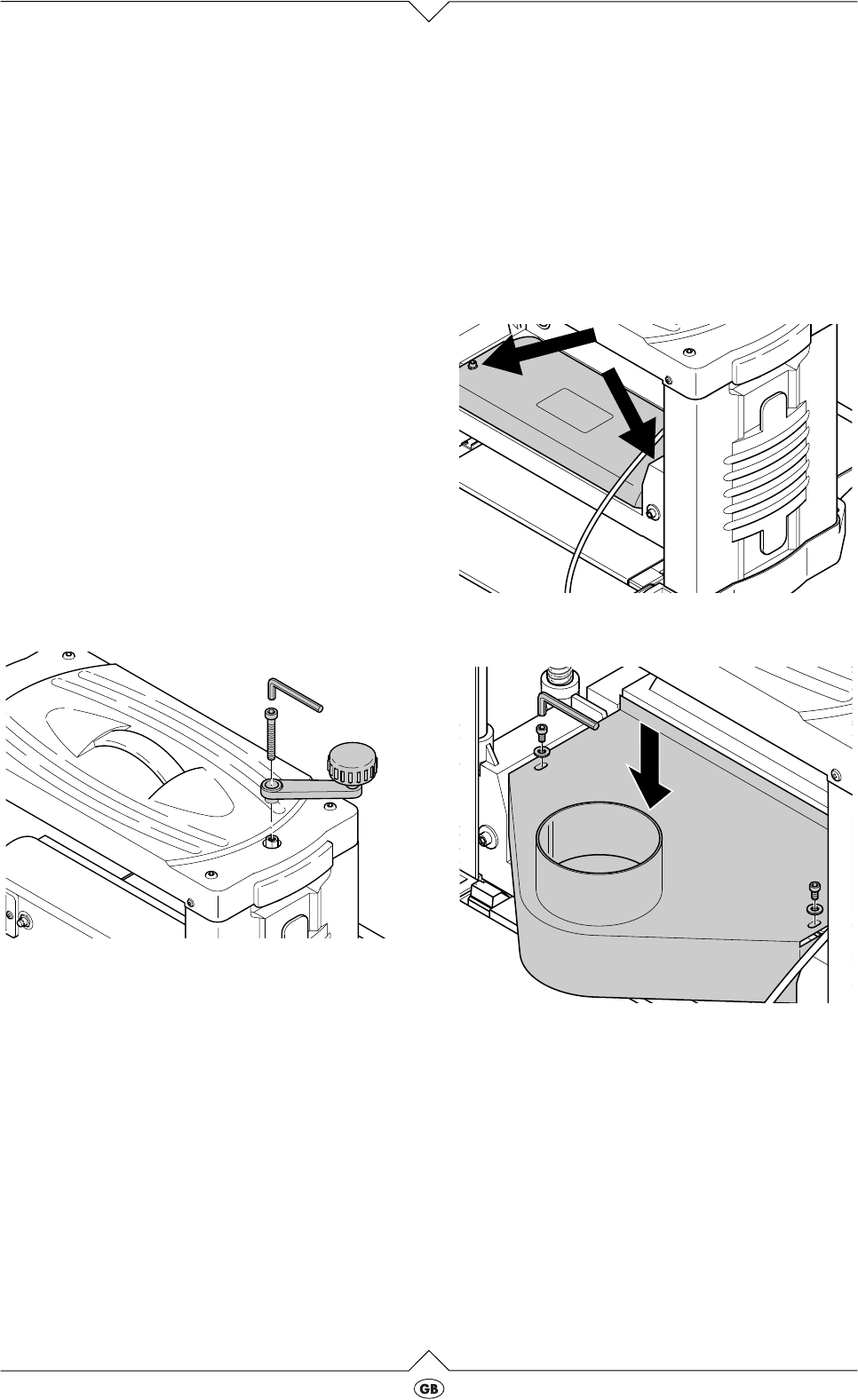

Fixing the planer

To keep the machine from „wandering” by vibra-

tions or from tipping over, it needs to be screwed to

a workbench, workstand or similar support:

1. Drill four holes into the support.

2. Fit screws through holes from the top and

secure from below with washers and nuts.

3

If the planer/thicknesser is to be used

mobile:

-

screw the planer to a sheet of 19 mm ply-

wood. This plywood sheet should on all

sides project approx. 100 mm over the

machine base. Make sure that the bolts do

not project from the underside of the ply-

wood sheet.

-

At the workplace, attach the plywood

sheet with G-clamps to a workbench,

workstand or similar support.

Installation of the rise and fall mecha-

nism crank

·

Place crank on the shaft and secure with a

screw.

Connection of a dust collector

A

Danger!

Some kinds of wooden dust (e.g. from oak

and ash) can be carcinogenic when inhaled.

Always connect to a suitable dust collector

(air speed at the planer's dust collection port

³

20 m/s) when working indoors.

A

Caution!

Operation without a dust collector

is only possible:

-

outdoors;

-

if only small amounts of chips are produ-

ced (with narrow stock and only slight chip

removal);

-

with a dust mask.

If no dust collector is used there is chip build-

up inside the housing, particularly at the cut-

ter knives. These remains cause a rough

surface. Therefore the chips need to be

removed regularly.

A

Danger!

Always unplug before removing the cutter-

block cover!

1. Unscrew both screws and remove the cutter-

block cover from the planer.

2. Fit dust extraction adaptor instead of the cutter-

block cover and secure with two screws.

3. Connect the suction port to a suitable dust col-

lector.

DO

WN

UP