14

ENGLISH

Risk of injury by inhaling wood

dust!

Dust of certain timber species (e.g.

beech, oak, ash) can cause cancer

when inhaled: Use a suitable dust collec-

tor (see "Technical Specifications").

Hazard generated by electric

tool defects!

Keep electric tool and accessories in

good repair. Observe the maintenance

instructions.

Check electric tool for possible damage

before any use: Before operating the

electric tool all safety devices, protection

devices or slightly damaged parts must

be inspected for proper functioning as

specified. Check to see that all moving

parts work properly and do not jam. All

parts must be correctly installed and

meet all conditions necessary for the

proper operation of the electric tool.

Damaged protection devices or parts

must be repaired or replaced by an qual-

ified specialist. Have damaged switches

replaced by a service centre. Do not

operate electric tool if the switch can not

be turned ON or OFF.

Keep handles free of oil and grease.

3.3 Symbols shown on the

circular saw

Danger!

Disregard of the following

warnings can lead to severe personal

injury or material damage.

Read instructions.

Do not reach into the revolving

saw blade.

Wear hearing protection.

Use push stick if

distance between

saw blade and rip

fence is ≤ 120 mm.

Cut round stock

only with a suitable

holding device.

Use table exten-

sion, if otherwise

workpiece would

fall off the table

after cutting.

3.4 Symbols used through-

out these instructions

Danger!

Indicates risk of personal

injury or severe material

damage.

Risk of electric shock!

Risk of personal injury by elec-

tric shock.

Drawing-in/trapping hazard!

Risk of personal injury by body

parts or clothing being drawn

into the rotating saw blade.

Caution!

Risk of material damage

Note:

Supplementary information

3.5 Safety devices

Blade guard

The blade guard (13) protects against

unintentional contact with the saw blade

and from chips flying about.

Always have blade guard installed dur-

ing operation.

Riving knife

The riving knife (14) prevents the work-

piece from being caught by the rising

teeth of the saw blade and being thrown

against the operator.

Always have riving knife installed during

operation.

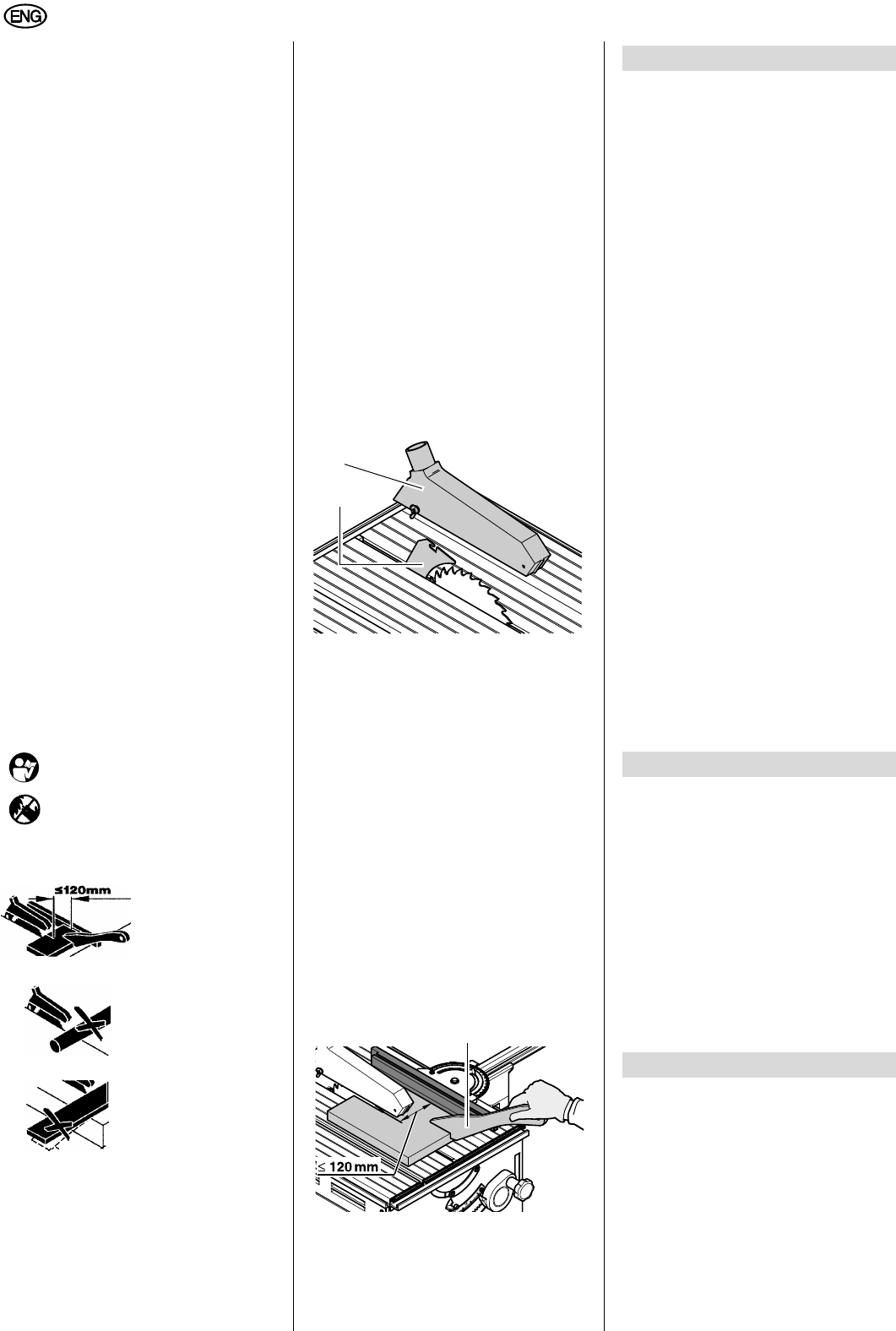

Push stick

The push stick (15) serves as an exten-

sion of the hand and protects against

accidental contact with the saw blade.

Use push stick if distance rip fence –

saw blade is ≤ 120 mm.

In order for the push stick to be always

at hand, it can be stored in a sheath

inside the machine's housing.

• Radial pull action for precision cuts.

• Precisely adjustable bevel tilt from

–1.5° through 46.5°.

• Steplessly adjustable depth of cut 0

– 65 mm.

• All operating elements are located

at the machine's front.

• Electronic speed control:

− motor soft start;

− low mains supply load;

− constant saw blade speed irre-

spective of load provides for con-

sistent cut quality;

− extended service life of the car-

bon brushes;

− low no-load speed results in less

annoyance by noise.

• An electronic motor protection by

overcurrent detection shuts the

motor off when it is locked (e.g. by a

blocked saw blade).

• An undervoltage relay prevents the

machine from starting up when

power is restored after a power fail-

ure.

• Compact design for quick and easy

transportation.

• Dustproof linear ball bearings, lubri-

cated for life, permanently maintain

guiding accuracy.

• Universal fence included in standard

delivery.

• Lower saw blade fully.

• Dismount add-on parts (fence, slid-

ing carriage, table side extension,

table rear extension).

• If possible use original carton for

shipping.

Caution!

For carrying use the handle

holes on the sides of the machine. Do

not carry the machine holding it by

any of the safety devices or operating

elements!

ON/OFF switch with emergency stop

• To switch ON = depress upper but-

ton (16).

• To switch OFF = push lower button

(17) or on switch cover.

13

14

15

4. Special Product Features

5. Transportation

6. Operating Elements