18

ENGLISH

Danger!

Use only suitable saw blades

according to EN 847-1 (see"Technical

Specifications" – when using unsuita-

ble or damaged blades parts could be

explosive-like hurled from it by cen-

trifugal force.

Do not use:

− saw blades which permissible

maximum speed is below the

rated no-load speed of the saw

spindle (see "Technical Specifica-

tions");

− saw blades made of high speed

steel (HSS);

− saw blades with visible damage;

− cut-off wheel blades.

Danger!

− Mount saw blade only using

genuine parts.

− Do not use loose-fitting reducing

rings; the saw blade could work

loose.

− Saw blades have to be mounted

in such way that they do not

wobble or run out of balance, and

can not work loose during opera-

tion.

8. Slide outer blade collar onto blade

spindle (observe centring of blade

collar).

9. Screw in arbor bolt (L.H. thread!)

and tighten fingertight with the

Allen wrench supplied.

Danger!

− Do not extend arbor bolt tighte-

ning wrench.

− Do not tighten arbor bolt by hit-

ting the Allen key.

10. Fasten cover plate to chip case.

11. Fasten removable table section.

12. Attach blade guard.

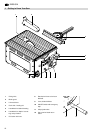

9.2 Scale setting

The scale can be set to correspond with

the saw blade thickness:

1. Loosen fixing screws and adjust

scale as required (38).

2. Tighten fixing screws and verify set-

ting by making a trial cut.

9.3 Blade tilt stop setting

1. Set the blade tilt limiter (39) to the

left (0° to 45° position).

2. Check blade bevel angle:

− 0° = square with the saw table

− 45° with separate mitre square.

If these angles are not exactly

matched:

3. Remove removable table section.

4. Adjust setting screws (40) of stops

until the blade tilt against the saw

table at the end positions is exactly

0° (= square) and 45° respectively.

5. After adjusting the stops the angle

scale at the machine front may need

readjustment.

6. Fasten removable table section.

9.4 Motorhead carriage com-

pensation setting

The compensation of the blade return

action has to be set so that the motor-

head carriage returns completely on its

own, without hitting the end position and

coming to a sudden stop.

• Turn clockwise = more damping

• Turn counter-clockwise = less

damping

9.5 Saw cleaning

1. Lay machine on its side.

2. Remove chips and saw dust with

vacuum cleaner or brush:

− from saw blade setting guide ele-

ments;

− from motor vent slots.

9.6 Machine storage

Danger!

Store saw so that

− it can not be started by unauthori-

zed persons and

− nobody can get hurt.

Caution!

Do not store saw unprotected

outdoors or in damp environment.

Note:

The ON/OFF buttons can be

blocked by a padlock.

9.7 Maintenance

Before switching on

Visual check if distance saw blade – riv-

ing knife is 3...8 mm.

Visual check of power cable and power

cable plug for damage; if necessary

have damaged parts replaced by a qual-

ified electrician.

Monthly (if used daily)

remove saw dust and chips with vacuum

or brush; apply light coat of oil to guide

elements:

− threaded rod and guide rods of

blade rise and fall mechanismn:

− connecting rods;

− swivel segments;

− damper.

Every 300 hours of operation

Check all screwed joints, retighten if

necessary.

38

0°-45°

-1,5°-46,5°

39

40