1.

2.

3.

4.

16

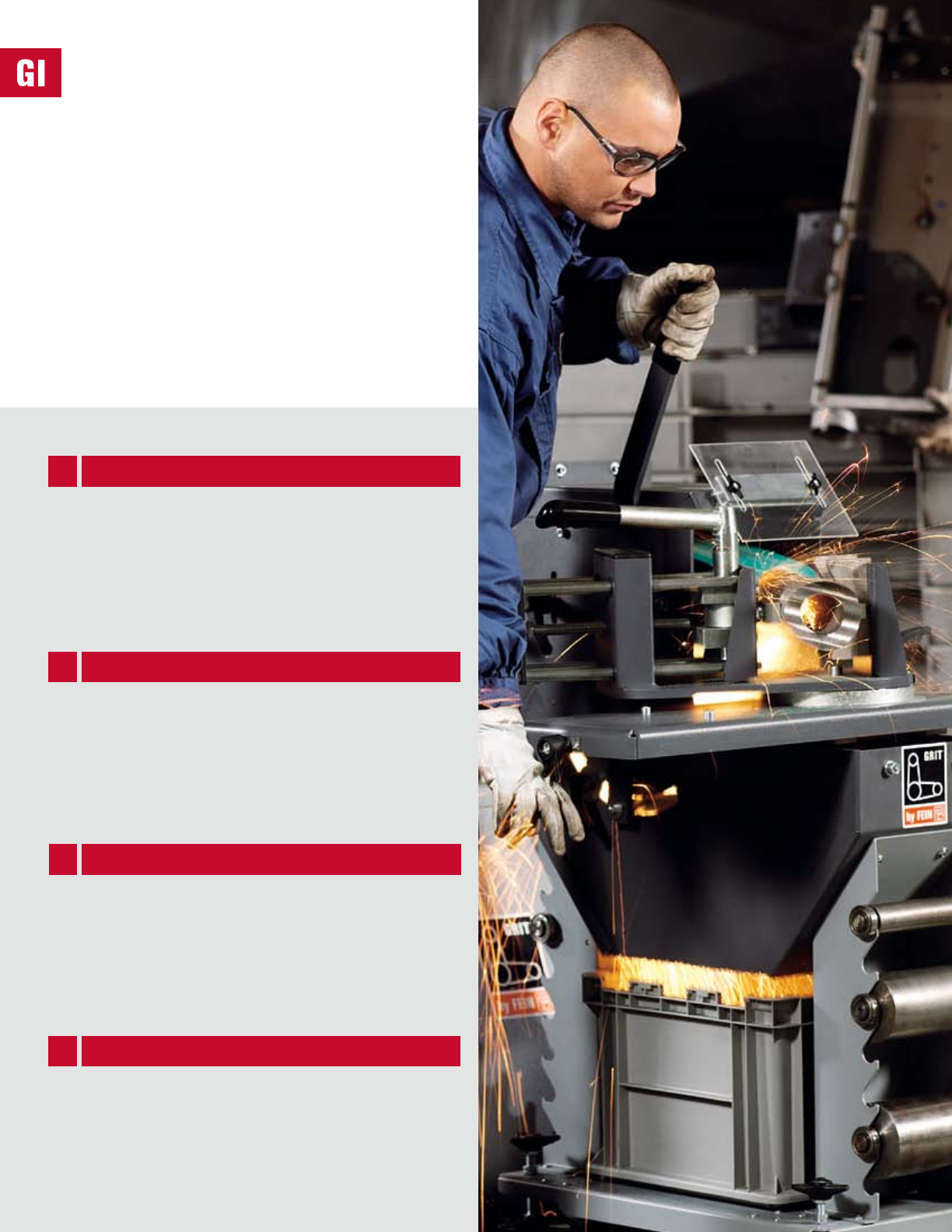

GRIT GI –

for use in industry

Developed especially for heavy-duty work in industry, the

GI program stands out because of its power and efciency.

All elements are extremely durable, high loads and long service

life are a standard feature of the GRIT GI machine – just as high

operational reliability and simple operation.

GRIT GI machines process all materials and applications that

are common in the metal industry: steel, stainless steel and

non-ferrous metals – in at, round or square proles. All

grinding applications are covered by the GI program: Flat,

cylindrical and abrasive grinding as well as sanding down,

radius grinding, chamfering and deburring.

Professional applications in industrial settings require high

demands – these demands are achieved throughout the

GI program. Durable construction and extremely powerful

motors; a GI machine runs reliably day in and day out.

Partially automated cycles make operations even easier.

The acquisition costs for GRIT GI machines are quickly

recovered. Work is done quickly and efciently with high

quality results.

The GRIT GI program is modularly designed: Depending

on the application you can assemble the ideal machine –

from the machine base with or without extraction and the

basic machine to the grinding module. If the job situation

changes, then a radius grinder for example is quickly con-

verted to a surface grinder.

Broadrangeofapplications

Constructedforindustrialuse

Quicklyamortised

Economic