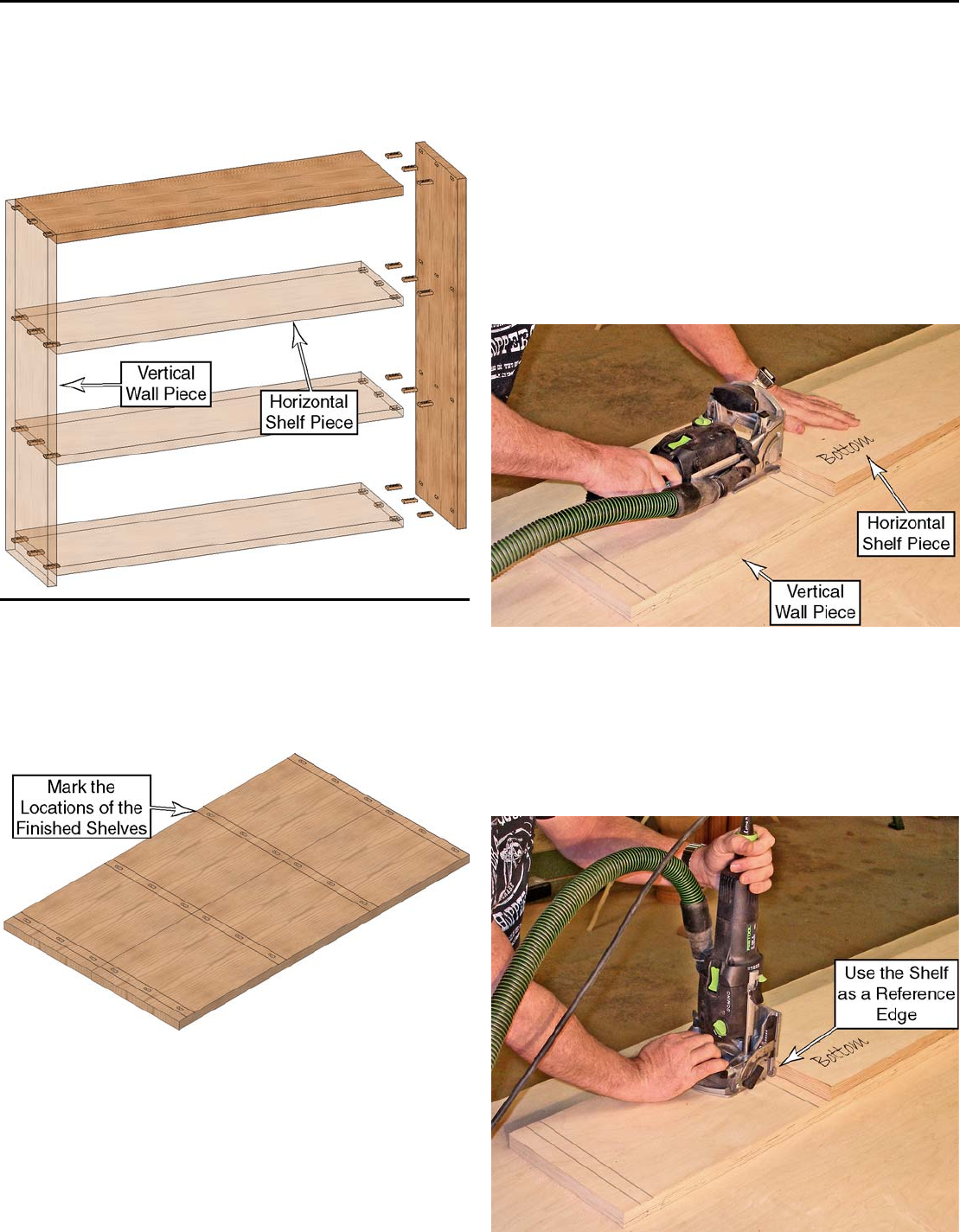

Making Carcase Butt Joints

Using tenoned butt joints is an effective method for

constructing a cabinet carcase. The tenons provide a strong

support for each of the horizontal partitions of the cabinet.

The simplicity of this method is that you use the carcase

components for aligning the joiner.

Instruction Manual 17

Setup and Machining

1. Lay the vertical wall pieces on your workbench, and

draw lines across both pieces to indicate where the

shelves will be located. Note that it is easier to avoid

mistakes later on by drawing double lines, with one line

above the shelf and one line below the shelf as shown.

2. For reference, label the top and bottom face of each

shelf. This is so your left- and right-hand mortises are

referenced from the same face of each shelf.

3. Working with one shelf at a time, lay the horizontal

shelf on top of the vertical wall so its edge lines up with

the outside pencil line for that shelf location.

Hint: Stand the shelf vertical on the side wall piece and

in the position it will eventually be secured (between the

double pencil lines), and carefully tip the shelf flat, into

the position shown in the photographs below. For

greater shelf-strength, keep the tenons closer to the

bottom-side of the shelf:

► If the shelf is thick (greater than 20mm), tip it down

with the top-side facing up.

► If the shelf is thin (less than 20mm), tip it down with

the bottom-side facing up.

4. Clamp the two pieces together to prevent them from

moving.

5. With the Domino baseplate resting on the face of the

wall-piece, plunge the joiner into the edge of the shelf.

Do not use the fence for height positioning.

6. With the joiner standing upright and its baseplate

against the edge of the shelf, plunge downward into the

side wall of the cabinet.

7. Repeat these steps for each of the shelves.

8. When you repeat this process for the other side wall,

make sure you keep the same side of the shelf facing up.