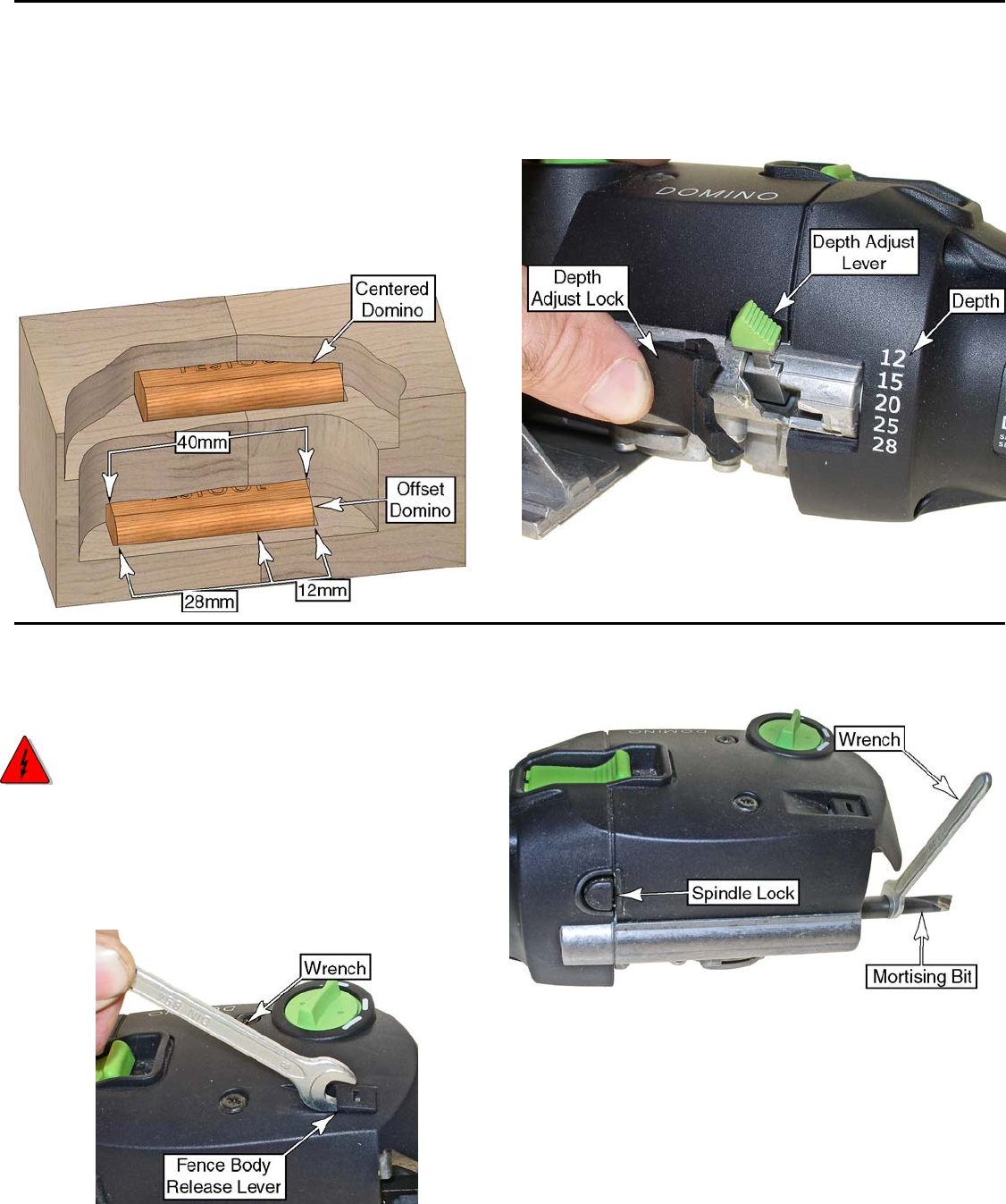

Setting the Mortise Depth

The mortising depth determines how deep into the

workpiece the mortising bit penetrates. This needs to be

adjusted for different sized tenons. In most cases, the tenon

should be centered across the joint, and the depth of the

mortise should be ½ the length of the tenon. However, in

some cases you may want to have more of the tenon in one

piece than the other (lower Domino tenon pictured below).

In this case, the sum of the two depths must equal the length

of the tenon. (In the offset tenon example below, the Domino

tenon is 40 mm long, the left mortise is 28 mm deep, and the

right mortise is 12 mm deep.)

1. Press in on the depth adjust lock.

2. Move the depth adjust lever to the stepped position of

the desired depth.

3. Release the depth adjust lock.

Changing the Mortising Bit

Different mortising bits are available for a variety of Domino

tenon sizes. The DF500 comes equipped with a 5mm bit, and

6, 8, and 10 mm bits are available as an option.

WARNING: Always unplug the tool before changing

mortising bits, or removing the fence body from the

motor housing.

1. Using the provided 8mm wrench, pry up on the fence

body release lever, and slide the fence body off the

motor housing. (The inset photograph on page 6 shows

the fence body and motor housing when separated.)

2. Press and hold the spindle lock button. This stops the

spindle from turning while you loosen the mortising bit.

3. Loosen the mortising bit by turning it counterclockwise

(standard right-hand thread).

4. Insert a new mortising bit, and start the threads by hand

to avoid cross-threading.

5. Press in on the spindle lock while tightening the bit. Do

not over tighten the bit.

6. Carefully reinstall the fence body onto the motor housing,

and push the fence body in until the latch clicks.

► Make sure there is no sawdust inside the guide tubes

before inserting the fence body.

► Be careful not to damage the linear bearings (hollow

tubes) when reinstalling the fence body. If it does not

slide on easy, it means the fence is skewed with respect to

the bearings.

Instruction Manual 9