5

4.1

In this case, the extraction pipe (Ø 27 mm)

(4.1) of the extraction unit is connected to

the suction nozzle.

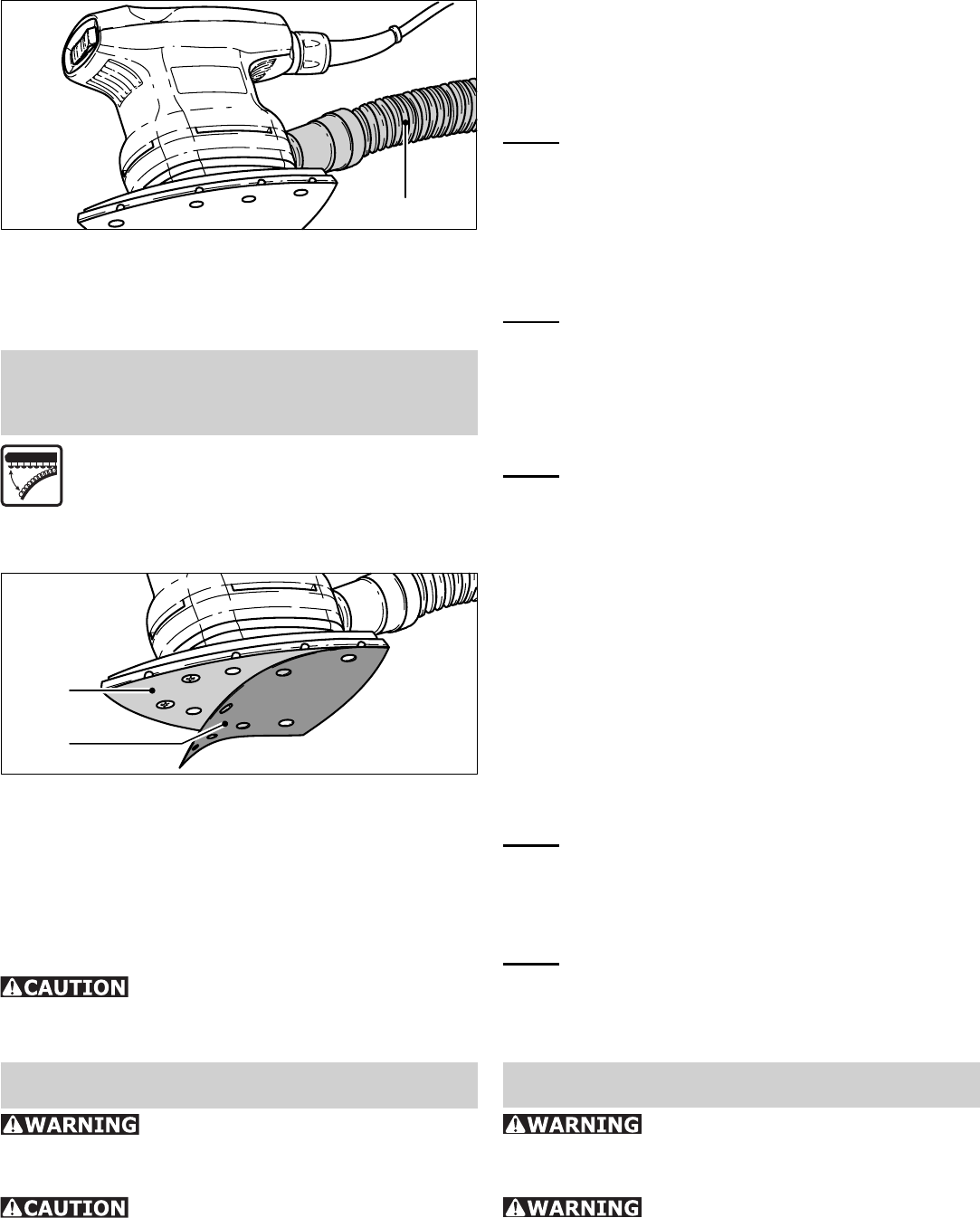

Attaching sand-

ing material

Stickfi x is a hook-and-loop fastening

system. Stickfi x sanding pads allow

the use of self-adhesive hook-and-loop

abrasives such as Stickfi x sandpapers

and sanding cloths.

5.2

5.1

Simply press the abrasive (5.1) onto the sand-

ing pad (5.2) and pull it off again after use.

Please note: Use only abrasives with an

undamaged Stickfi x hook-and-loop coating.

Before use, check that the coating has not

been damaged by improper use (such as

over heating).

Always use original Festool sand-

ing materials!

Working with the tool

Always secure the workpiece

in such a manner that it cannot move while

being sanded.

Never overload the tool by using

too much pressure! The best sanding results

are achieved when applying moderate pres-

sure.

The sanding performance and quality depend

mainly on the choice of the right sanding

material. Festool offers the appropriate sand-

ing material for all applications (see Festool

catalogue).

We recommend the following settings on the

rotary control (2.1) for electronic machines:

5 - 6

sanding with max. drive

sanding old paint

sanding wood and veneer prior to paint-

ing

interim sanding of paint on surfaces

4 - 5

sanding of thinly applied primer

sanding of wood with sanding vlies

sanding edges on wooden parts

smoothing primed wooden surfaces.

3 - 4

sanding full wooden and veneer edges

sanding in the grooves/rebates of windows

and doors

interim paint sanding on edges

pre-sanding natural wood windows with

sanding vlies

smoothing wood surfaces with sanding felt

prior to staining

rubbing down stained surfaces with sand-

ing vlies

rubbing down or removing excess lime

paste with sanding vlies

2 - 3

interim paint sanding on stained surfaces

cleaning natural wood window grooves with

sanding felt

1 - 2

sanding stained edges

sanding thermoplastic synthetics

Maintenance and care

Always remove the plug from

the mains supply socket before carrying out

any work on the machine!

Any maintenance or repair work

requiring the motor housing to be opened may

only be carried out by an authorised service

workshop.

The cooling air vents on the motor housing

must always be free of blockages and clean

to ensure air circulation.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•