4

1.1

1.2

Push the switch (1.1) forwards to start the ma-

chine. A slight pressure on the rear of the switch

is enough to switch the machine off.

When cold the machine may take a few minutes

to reach maximum speed. This is due to its con-

struction and is not serious.

Electronics

ELECTRONIC

When processing different surfaces it is

helpful to adjust the sanding speed to the

respective material.

The fi gures on the speed regulator (1.2) roughly

correspond with the following idling speeds:

strokes per min

1 10 000 4 15 400

2 11 800 5 17 200

3 13 600 6 19 400

Metalworking

Observe the following safety precau-

tions when working on metals:

• Pre-connect a residual current circuit-breaker

(FI, PRCD).

• Connect the tool to a suitable dust extractor.

• Regularly clear out any dust accumulations in

the motor housing.

• Wear protective goggles.

Tool settings

Always remove the power plug from

the socket before carrying out any work on the

power tool.

Dust extraction

2.1

In order to draw off the dust produced during

sanding the hose (Ø 27 mm) of a Festool dust

extractor is attached to the suction adapter (1.2)

at the end of the motor casing. The sanding dust

is then drawn off directly through the extractor

channel in the sanding pad.

When working with wood or if materials are used

which may produce harmful dusts the electrical

tool should be connected to a suitable extractor.

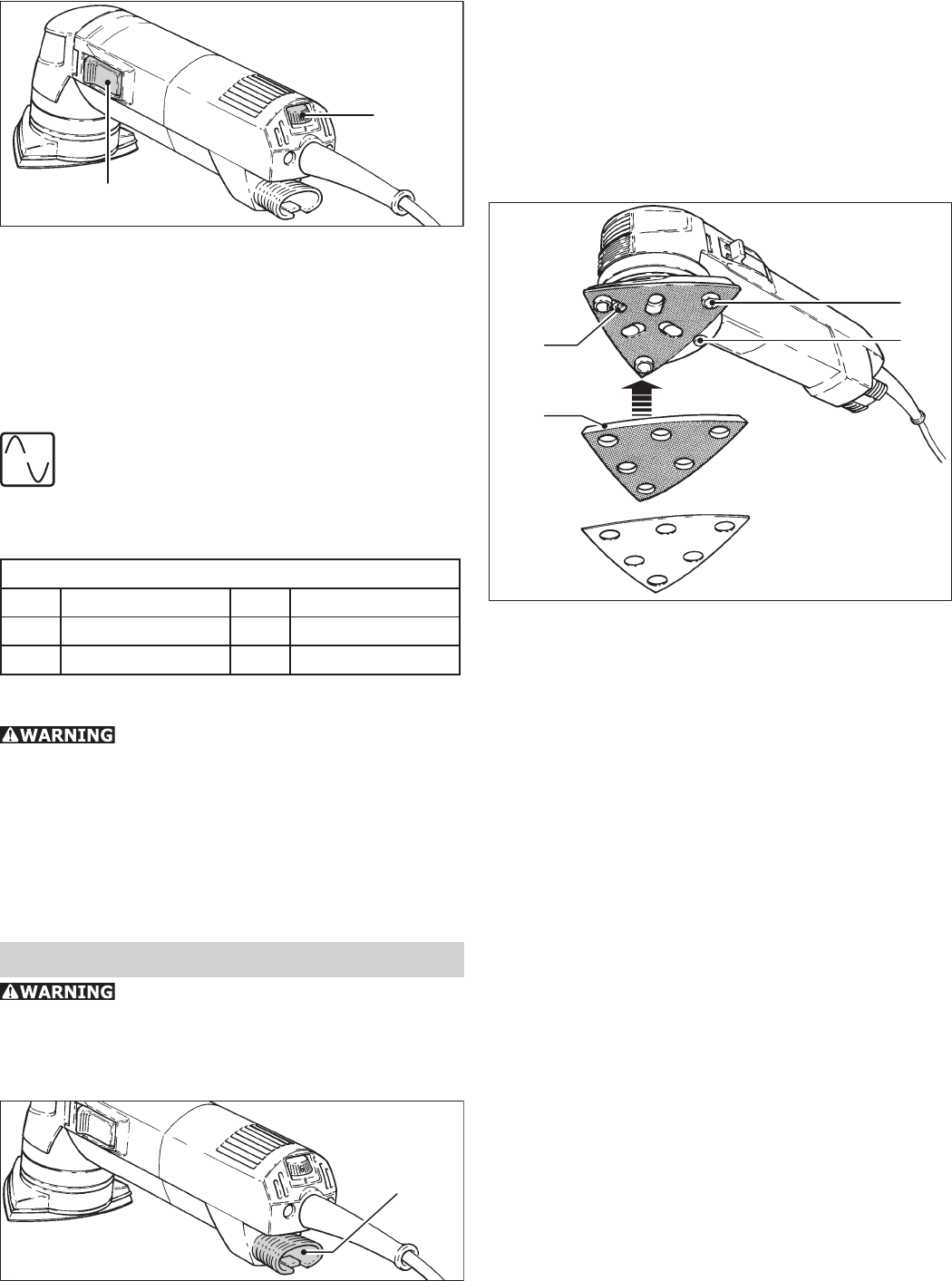

Sanding pad

3.1

3.2

3.3

3.4

3.5

The sanding pad is made of MPE foam (micro-cel-

lular polyurethane elastomer) and has bevelled

edges (3.3). It has a velour fabric on its top

surface and a Stickfi x covering on its underside.

The velour side of the sanding pad is pressed

against the Stickfi x covering of the sanding base

(3.4) The tool’s sanding base has three centring

protuberances (3.1) at its corners enabling easy

adjustment.

Please note:

The device has been specially developed for work

in corners and on edges. Experience has shown

that this leads to a more point-focal load on the

tip of the sanding base. The heat generated is

naturally higher than when working on the whole

surface since the same pressure is applied to

a smaller surface. Do not apply as much pres-

sure since otherwise the Stickfi x covering of the

sanding pad and the abrasive quickly become

damaged. If the Stickfi x covering on the front tip

of the sanding pad should become worn simply

remove the sanding pad, rotate around 120° and

replace.

If the Stickfi x covering of the sanding base should

become worn the complete base (487406) can

be replaced. Simply loosen the two screws (3.2

and 3.5).

Abrasive

Festool can offer perforated Stickfi x abrasives in

grain sizes from P 40 to P 400 for an effective