4

Class II Construction

rpm revolutions or reciprocation per minute

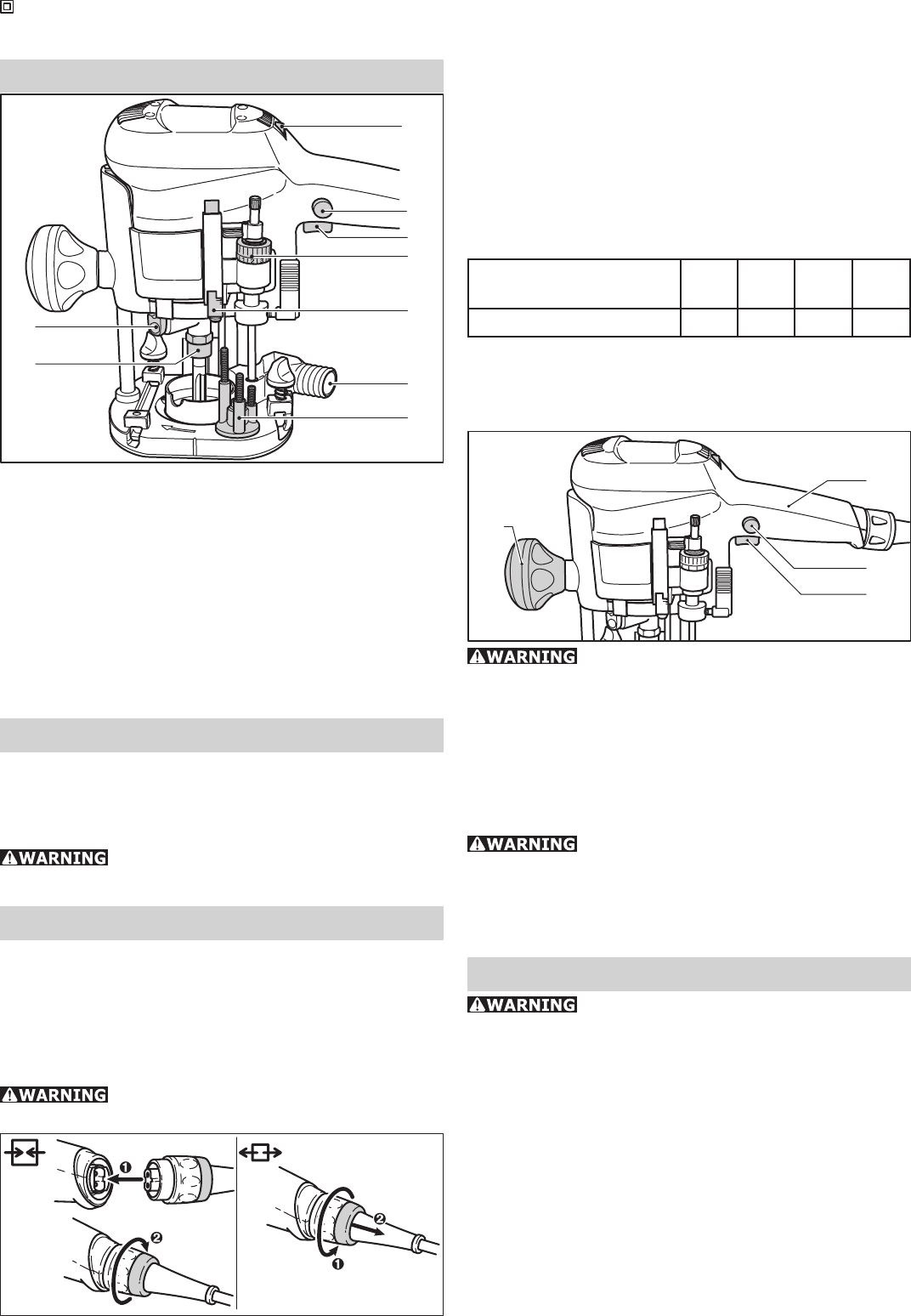

Functional description

1.1

1.2

1.3

1.4

1.5

1.7

1.6

1.9

1.8

0

1.1 Speed controller

1.2 Locking button

1.3 On/Off switch

1.4 Depth adjustment

1.5 Scale

1.6 Extractor connection piece

1.7 Pivoted turret stop

1.8 Collet nut

1.9 Spindle stop

Use for intended purpose

The routers are designed for routing wood, plastics

and similar materials. Aluminium and plasterboard

can also be processed with corresponding cutters

such as are listed in the Festool catalogues.

The user is liable for damages and

injuries due to incorrect usage.

Electrical connection

The network voltage must conform to the voltage

indicated on the rating plate. A 16 A safety fuse

(for 120 V) or a corresponding protective circuit-

breaker is required.

See the following fi gure for connection and discon-

nection of the power cable.

Always switch the machine off before

connecting or disconnecting the power cable!

2

Extension cable

If an extension cable is required, it must have a

suffi cient cross-section so as to prevent an exces-

sive drop in voltage or overheating. An excessive

drop in voltage reduces the output and can lead

to failure of the motor. The table below shows

you the correct cable diameter as a function of

the cable length for the router OF 1010 EQ. Use

only U.L. and CSA listed extension cables. Never

use two extension cables together. Instead, use

one long one.

Total Extension Cord

Lenght (feed)

25 50 100 150

Cord size (AWG) 18 16 14 12

Note: The lower the AWG number, the stronger

the cable.

Switching the machine on and off

3.2

3.1

3.3

3.4

Keep the machine steady during

switching and during use by holding the handle

(3.2) and the additional handle (3.1) with both

hands.

The switch (3.4) is used to switch the tool on and

off. For continuous operation the switch can be

locked by means of the button on the side (3.3).

The switch can be unlocked by pressing again.

After the machine has been switched

off, the milling cutter will still rotate for a time.

Take care that parts of your body do not come

into contact with the milling cutter while it is still

rotating!

Electronics

Do not work with the OF 1010 EQ if

the electronic control is defective since this may

lead to excessive speeds. A defect in the electronic

control is indicated by the absence of a smooth

run-up, a higher noise level at idle or the fact that

no speed control is possible.

The router OF 1010 EQ has solid shaft electronics

with the following functions:

Smooth start-up:

The electronically controlled smooth start-up

facility enables start-up of the machine without

jerks and requires a lower start-up current.