Setting the Blade Perpendicular to the Sole Plate

This adjustment ensures that cuts are made square to the

workpiece surface. This adjustment is completed at the

factory and shouldn’t need to be adjusted unless the tool has

been modified or serviced.

Instruction Manual 11

The most accurate method for checking the square of the

blade is to make a cut with the saw and examine the

resulting cut.

For even greater accuracy, the procedure below uses a

method that amplifies a small measurement into a larger

measurement to make it easier to observe. This doubles the

accuracy of the adjustment.

Adjustment Procedure

1. Using the guide rail, carefully cut a small piece of wood

in half.

► This is a precision adjustment. Make sure the guide rail

and workpiece are securely clamped.

► The piece should be at least ¾ inch thick by 12 inches

square.

► The thicker the piece, the more accurate the adjustment

will be.

► For best results, the material should have a consistent

center, such as Medium Density Fiberboard (MDF),

plastic, or solid lumber.

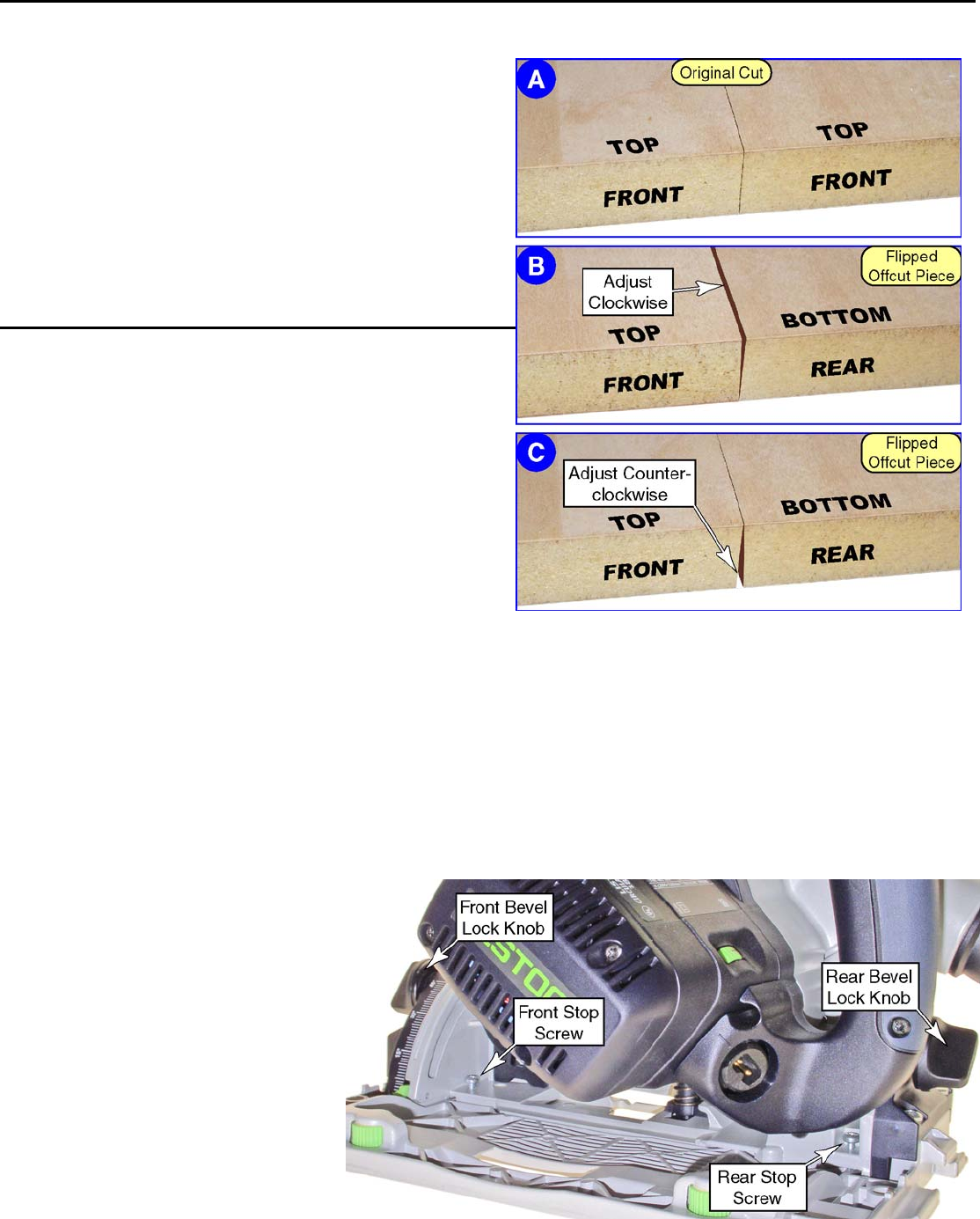

2. Place the two pieces back together to verify that the

original cut-line is tight (Figure A). If the cut-line is not

tight, make a new cut.

3. Flip the offcut board end-for-end so the cut-line is still

together but the board is upside down. (Don't flip the

board that was under the saw.)

4. Inspect the joint between the two boards:

► If there is no gap then the adjustment is correct.

► If the gap is at the top of the two boards (Figure B), then

turn the adjustment screws clockwise.

► If the gap is at the bottom of the two

boards (Figure C), then turn the

adjustment screws counterclockwise.

5. Loosen the front and rear bevel lock

knobs (see image to the right).

6. Turn the two stop screws in the direction determined in

step 4. (Make sure to turn both screws the same

amount.) Each turn of the adjustment screw will have

the following effect:

► 1 turn equals 1 degree of adjustment.

► 1 turn equals ½ mm of gap between the boards shown

above (assuming ¾ inch thick boards).

7. Verify the adjustment setting by repeating steps 1

through 4.