Depth Limited (Dado/Half-Lap) Cuts

WARNING! Never attempt to install or use a

dado blade in the Kapex saw. Using either a

stacked-dado or wobble-dado blade will exceed

the capacity of the arbor, and the blade may

impact the saw’s guards, resulting in personal

injury and damage to the saw.

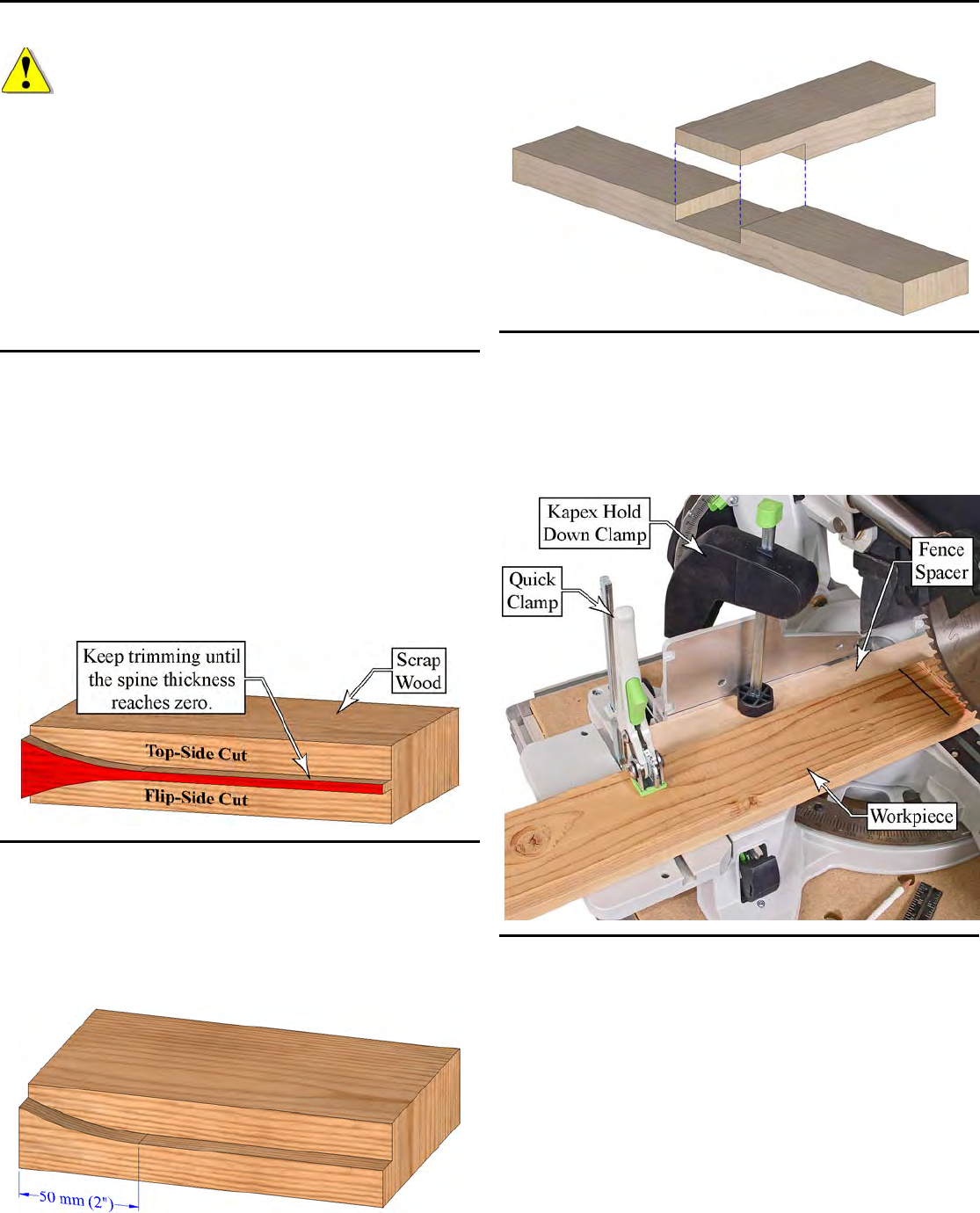

A dado is a special type of cut where the depth of the cut

does not go all the way through the workpiece. One

common example of this type of cut is for making half-

lapped joints, which is shown to the right and described

below. In a half-lap joint, material is removed from the

intersection of both workpieces comprising the joint. When

the joint is assembled, the pieces overlap, creating a

strong joint, but unlike a full-lap joint, the thickness of the

joint is equal to just the thickness of the workpieces.

Supplemental User’s Manual 19

Depth Setting

For making a half-lap joint, it is necessary to set the saw’s

cutting depth to be exactly in the center of the workpiece

thickness. The most accurate way of finding the center of a

board is to trim from both sides until the two cuts meet.

Use a piece of scrap wood that is the same thickness as

the actual workpiece. Starting with a depth setting that

you know to be less than half the workpiece thickness,

make a cut from the top side, and then flip the piece over

and make a second cut, as shown below by the Red color.

Gradually lower the depth of cut and repeat these two cuts

until the two cuts meet, and the spine reaches a zero-

thickness. This is exactly the center of the workpiece.

Fence Spacer

The center of the sawblade is 50 mm (2”) forward of the

saw’s fence, which results in the curved ramp at the rear

of the cut shown in the image below. To account for this

and remove the radius at the end of the cut, add a 50mm

(2”) spacer in front of the fence, and clamp it in place with

the Kapex hold down clamp as shown to the right.

Half-Lap Joint

Clamping

It is important that both the fence spacer and workpiece

are securely clamped to the saw for cutting. Use the Kapex

Hold Down Clamp (see page 12) to clamp the fence

spacer, and use an auxiliary clamp, such as a Festool

Quick Clamp or Screw clamp (see page 16) to secure the

workpiece.

Cutting the Dado

Before cutting the dado, mark the right and left sides of

the cut to indicate how wide the dado needs to be. Then

make successive kerf-cuts between the lines until all the

material between the lines is removed. The closer together

each of these successive cuts are, the smoother the

bottom of the dado will be. For best results, clean the

bottom of the dado with a sharp chisel.