8

9.1

A Festool dust extractor with an extractor

hose diameter of 36 mm or 27 mm (36 mm

recommended due to the reduced risk of clogging)

can be connected to the rotating extractor

connector (9.1)

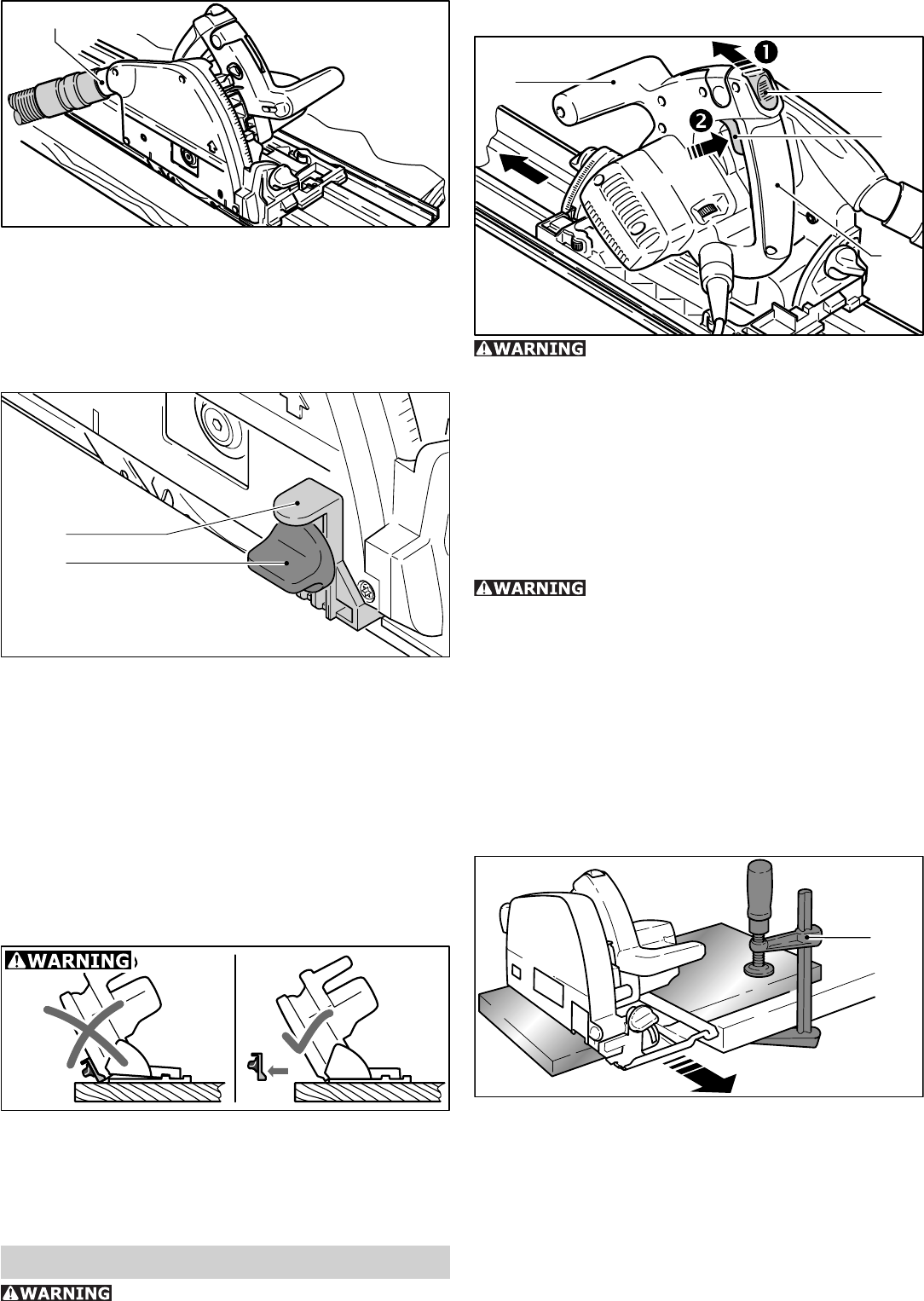

Mounting the splinterguard

10.1

10.2

The splinterguard (accessories) significantly

improves the quality of the cutting edge of the

sawn workpiece on the upper side for 0° cuts.

- Attach splinterguard (10.1) onto the protective

cover,

- Place machine onto the workpiece or the guide

rail,

- Press splinterguard down until it sits on the

workpiece and tighten it with the rotary knob

(10.2).

- Saw splinterguard in (machine to maximum

cutting depth and speed range 1).

Use the splinterguard only for 0° cuts. Al-

ways remove the splinterguard for mitre

cuts. When making mitre cuts, the splinterguard

raises the portable circular saw from the work-

piece, which can lead to serious injuries.

Operation

Read and understand the safety

instructions before starting work!

Switching the machine on and off

11.1

11.3

11.4

11.2

Keep the machine steady during

switching and during use by holding the handle

(11.2) and the additional handle (11.1) with both

hands.

To switch on, fi rst push the cut-in and release

block (11.4) forwards, and then press the „On“-

“Off“ switch (11.3). You can then press the

machines down for sawing, and release the cut-

in and release block.

To switch off, release the „On“-“Off“ switch.

After the machine has been switched

off, the saw blade will still rotate for a time.

Take care that parts of your body do not come

into contact with the saw blade while it is still

rotating!

As soon as you remove the machine from the

workpiece once sawing has been completed, the

machine automatically returns to its basic position

and the saw blade is again completely covered by

the protective covering.

Support of the workpieces

12.1

Ensure that your workpieces are securely fi xed

and cannot move during sawing. Otherwise,

there is an increased risk of accident. Never

hold the workpiece to be cut with your hands or

between your legs. Use instead screw clamps

(12.1) or some other suitable devices to fi x your

workpiece.