14

3.6 CLEAN SPARK ARRESTOR

The engine exhaust muffler has a spark arrestor screen. Inspect and

clean the screen every 200 hours of operation or once each year,

whichever comes first.

NOTE:

If using the generator on any forest-covered, brush-covered or

grass-covered unimproved land, it must equipped with a spark

arrestor. The spark arrestor must be maintained in good condi-

tion by the owner/operator.

Clean and inspect the spark arrestor as follows:

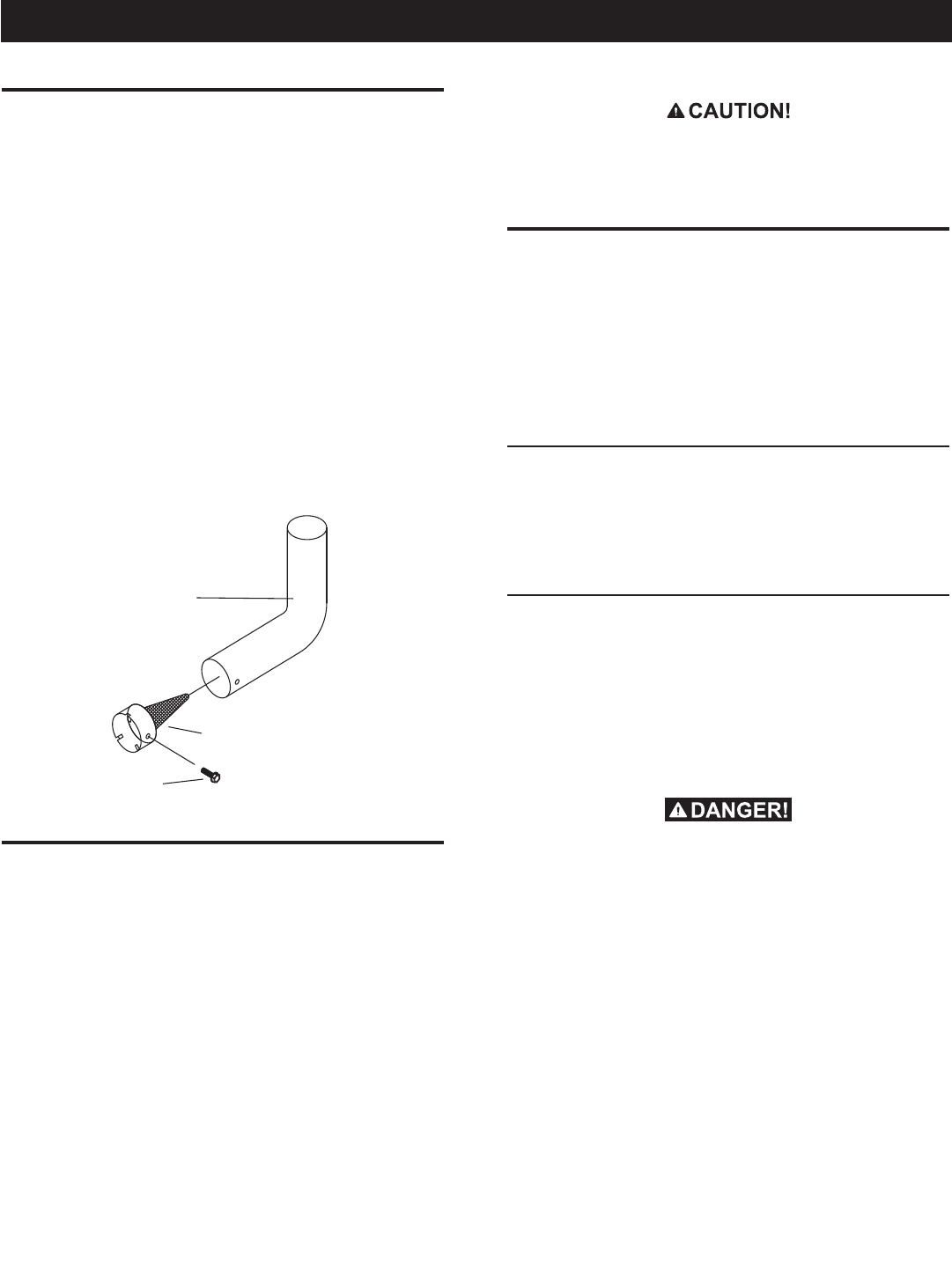

Remove the screen by removing the screw.•

Slide the spark arrestor screen out from the tail pipe.•

Inspect screen and replace if torn, perforated or otherwise •

damaged. DO NOT USE a defective screen. If screen is not

damaged, clean it with commercial solvent.

Replace the screen and the screw.•

Figure 3.6 - Spark Arrestor

RETAINING

SCREW P/N 056892

SPARK ARRRESTOR

SCREEN P/N 089680

TAILPIPE

P/N 0G5857

3.7 CLEANING THE GENERATOR

Keep the generator set as clean and dry as possible. Protect the

unit against excessive dust, dirt, corrosive vapors, road splash,

etc. Permitting dirt and moisture to accumulate on generator

windings will have an adverse effect on the insulation resistance

of those windings.

When moisture is allowed to remain in contact with windings,

some of the moisture will be retained in voids and cracks in the

insulation. This causes a reduced insulation resistance and will

eventually cause problems. Dirt will make the problem worse,

since dirt tends to hold moisture in contact with windings. Salt (as

from sea air) also will worsen the problem since it tends to absorb

moisture from the air. Salt and moisture, when combined, form a

good electrical conductor which is detrimental to the generator.

n

Do NOT use a forceful spray of water to

clean the generator. Water will enter the gen-

erator interior and cause problems, and may

also contaminate the generator fuel system.

3.8 BATTERY MAINTENANCE

NOTE:

This generator is not equipped with an internal battery charger.

It is intended for use in systems where an external battery char-

ger is installed by the RV O.E.M. or an aftermarket installer.

All lead-acid batteries will discharge when not in use. The generator

battery should be inspected as follows:

3.8.1 WEEKLY

Inspect the battery posts and cables for tightness and corro-•

sion. Tighten and clean as necessary.

Check the battery fluid level of unsealed batteries and, if nec-•

essary, fill with Distilled Water Only. Do not use tap water in

batteries.

3.8.2 EVERY SIX MONTHS

Have the state of charge and condition checked. This should be •

done with an automotive-type battery hydrometer.

NOTE:

Servicing of the battery is to be performed or supervised by

personnel knowledgeable of batteries and the required precau-

tions. Keep unauthorized personnel away from batteries.

Damage will result if the battery connections are made in

reverse.

Do not dispose of the battery in a fire. The

battery is capable of exploding. Storage bat-

teries give off explosive hydrogen gas. This

gas can form an explosive mixture around

the battery for several hours after charging.

The slightest spark can ignite the gas and

cause an explosion. Such an explosion can

shatter the battery and cause blindness or

other injury. Any area that houses a storage

battery must be properly ventilated. Do not

allow smoking, open flame, sparks, or any

spark producing tools or equipment near the

battery. Discharge static electricity from body

before touching the battery by first touching

a grounded metal surface.

Maintenance