11

English

4.Slidethetoolresttowithinamaximumof1/16"(1.5mm)fromthewheel.Rotatethewheelonefull

revolutionbyhandtoensurethewheeldoesnotcontactthetoolrest.

5.Tightenthelockingknobrmlytoretaintheassembly.

6.RepeattheassemblyoperationfortheRIGHTtoolrest.

Mounting Bench Grinder

Ifduringoperationofthebenchgrinderthereisanytendencyforthegrindertoslideor"walk"orto

tipover,thenthegrindermustbesecuredtoaworkbenchorothersupportingsurfaceusingfasteners

(notsupplied)throughthetwoholesinthegrinderbase.

Beforemountingthegrindertoaworkbenchorsimilarsurface,determinetheidealmountingposition

byperformingaseriesofnon-poweredtestswithitemsthatwilltypicallybeusedonthegrinder(e.g.

lawnmowerblades,scissors,knives,woodchisels,woodturningtools,etc.)Thesetestsrunswillhelp

determinehowneartheworkbenchedgethegrindershouldbemountedsothatthebenchtopdoes

interferewithgrindingoperations.Besuretheworkbenchorpedestaltowhichthebenchgrinder

willbemountedisat,level,andsturdyenoughtobeartheweightofthegrinder,othertools,andthe

materialbeingworked.

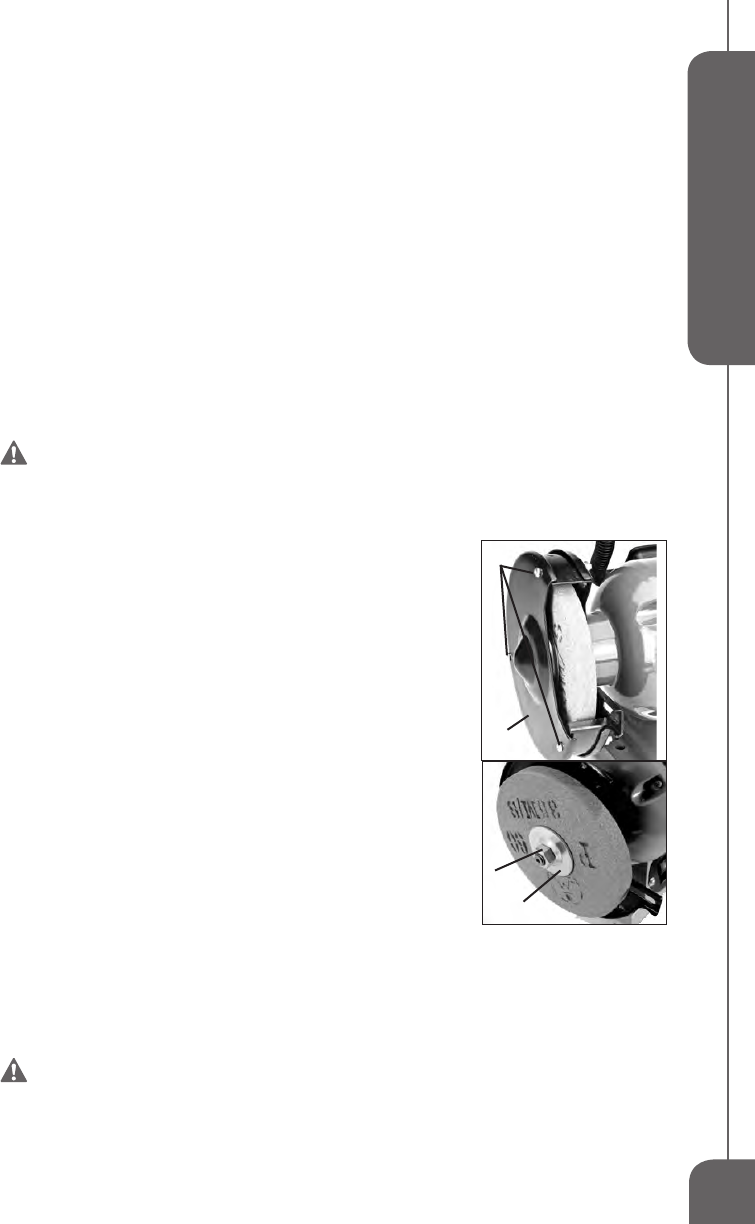

Changing the Grinding Wheels (FIG 7)

WARNING: Useonlygrindingwheelsratedfor3,600rpmorhigherwith

a1/2"arborholeorappropriatesizedbushing.Neveruseagrindingwheel

ratedlowerthan3,600rpmorattempttomachineanundersizedwheeltot

the arbor.

1.Removethethreebolts(1)attachingtheprotectivesidecover(2)to

thegrinder;thenremovethesidecover.

2.Preventtheshaftfromrotatingbyplacingawedgebetweenthe

wheelandthetoolrest.

3.Facingthefrontofthebenchgrinder:toreplacethewheelon

theleftside,turnthearbornut(3)clockwisetoloosenand

counterclockwisetotightenthearbornut.

4.Toreplacethewheelontheright:turncounterclockwisetoloosen

andclockwisetotighten.

NOTE:Manygrindingwheelsuseremovableandadjustablearbor

bushingstoallowadaptationtovariousmachinearbordiameters.

Savethisbushingforfutureuseifnotneededtoinstallthe

replacementwheel.

5.Removethearbornut(3),outerange(4)andtheoldwheel.

6.Installthereplacementwheelandouterangeontheshaft.Make

surethewheelisslidet(notloose)ontheshaft.

7.Replacethearbornutandtighten.

8.Replacethesidecover.Reinsertthethreeboltsandtightentheside

coverinplace.

9.Re-adjusttoolrest,sparkguardandeyeshield.

10.Rotatethewheelbyhandtocheckfreemovementandproper

adjustments.

WARNING: Do not overtighten wheel nuts when installing grinding

wheels. Tighten the wheel nut enough to drive the wheel and prevent slippage.

1

FIG 7

2

4

3