11

Maintenance

WARNING. Always ensure that the tool is switched off and

the plug is removed from the power point before making any

adjustments or maintenance procedures.

1. Keep the tool’s air vents unclogged and clean at all times.

2. Regularly check to see if any dust or foreign matter has

entered the grills near the motor and around the on/off

switch. Use a soft brush to remove any accumulated dust.

Wear safety glasses to protect your eyes whilst cleaning.

3. If the body of the tool needs cleaning, wipe it with a soft

damp cloth. A mild detergent can be used but nothing like

alcohol, petrol or other cleaning agents.

4. Never use caustic agents to clean plastic parts.

CAUTION. Water must never come into contact with

the tool.

5. Lubricate all moving parts at regular intervals.

Note. Do not at any time let brake fluid, petrol or petroleum-

based products, penetrating oils, etc., come in contact with

plastic parts. They can damage, weaken or destroy plastic

which may result in serious personal injury.

Electric tools used on fibreglass material, wallboard,

spackling compounds, or plaster are subject to accelerated

wear and possible premature failure because the fibreglass

chips and grindings are highly abrasive to bearings,

brushes, commutators, etc. Consequently, we do not

recommend using this tool for extended work on these

types of materials. However, if you do work with any of

these materials, it is extremely important to clean the tool

using compressed air.

Brush replacement

The impact wrench has externally accessible brush

assemblies that should be periodically checked for wear.

To check and replace the brushes follow the below

instructions.

1. Unplug the impact wrench.

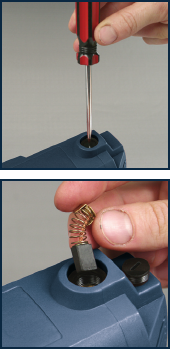

2. With a flathead screwdriver,

remove the bush caps. The

brush assembly is spring

loaded and will pop out when

you remove the brush cap.

3. Remove the brush assembly

(brush and spring). Check for

wear. If worn, replace.

Note: always replace in pairs.

Do not replace one side without

replacing the other.

4. Replace the brush assembly.

5. Replace the brush cover and

tighten with a screwdriver.

Note: be careful not to

overtighten.

General Inspection

Regularly check that all the fixing screws are tight.

They may vibrate loose over time.

Power cord maintenance

If the supply cord needs replacing, the task must be carried

out by the manufacturer, the manufacturer’s agent, or an

authorised service centre in order to avoid a safety hazard.