10

3. When set at right angles to

the planer base, the fence

provides a guide to help

control the planing action.

Note. The fence can be fitted

to either side of the base.

Note. The angle graduations

marked on the fence are for

indicative purposes only. For

accurate bevel cutting it is necessary to measure the angle

of the fence, make a trial cut and adjust if necessary.

Shavings extraction

1. The dust/chip extraction

port (6) allows connection

to a vacuum dust extraction

system.

2. Using the dust extraction

adaptor (18) permits a

dust extraction system to

be connected to the dust

extraction port (6).

3. To fit the adaptor (18) insert it into the port (6) and twist it

clockwise until it locks into position.

Removing and installing planer blades

CAUTION. Always ensure that the tool is switched off

and unplugged from the power supply before installing or

removing blades.

Your planer is fitted with reversible blades. Blades can be

reversed when blunt. After both sides of the blades have

been used they should be discarded.

Note: These blades cannot be re-sharpened.

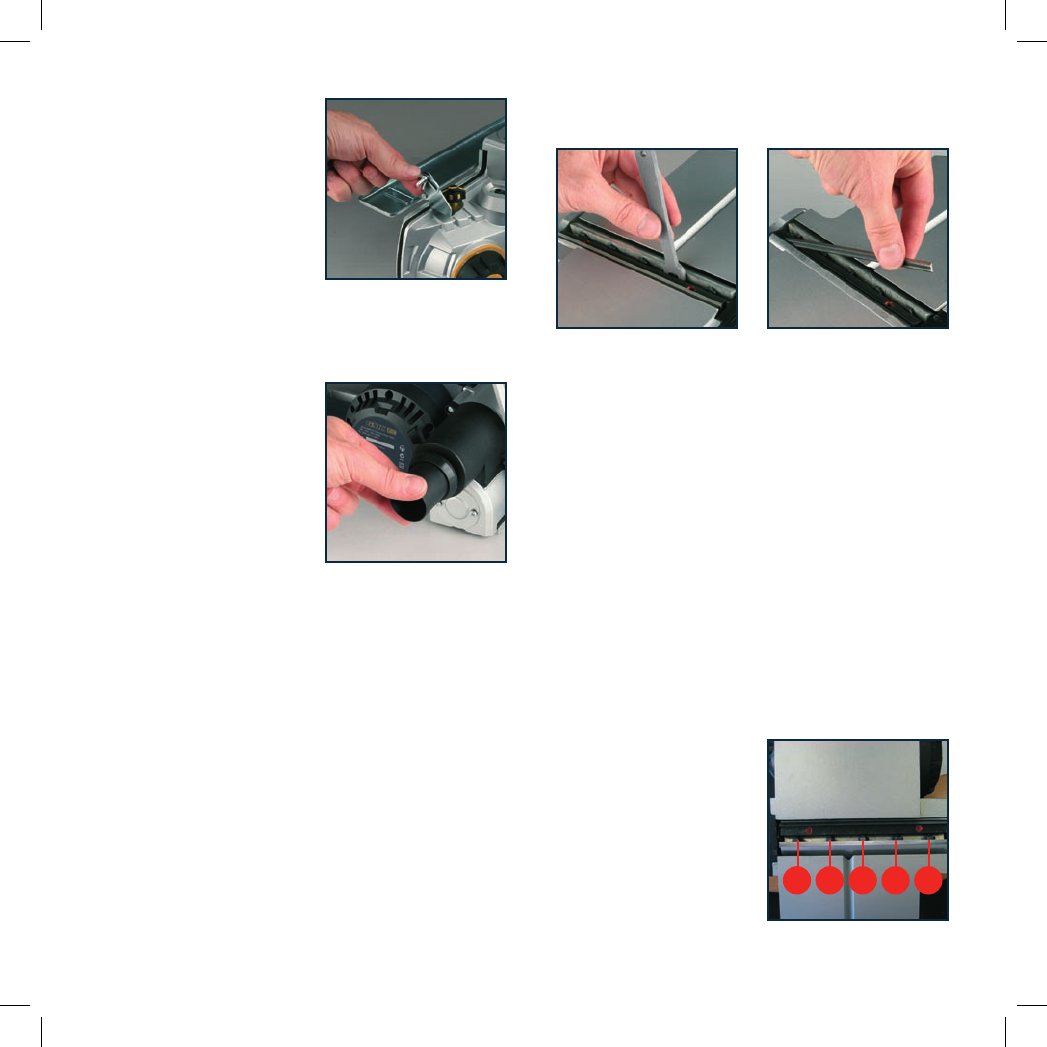

Removing a planer blade

CAUTION. The blades are very sharp. Take care when

handling them.

1. Using the supplied spanner (19), loosen the five clamping

screws (11).

2. Remove the planer blade (9) from the slot in the blade

barrel (10) in which it is retained.

Installing a planer blade

1. The blades are reversible as they have a cutting edge on

both sides. If a blade edge is worn or damaged, the blade

can be removed and put back the other way around.

Either turn over the planer blade (9) or replace it if

required.

2. Slide the good blade face up into the blade support block

of the blade barrel (10).

Note. If only one blade is damaged, it can be replaced

without the need to replace the other two blades. When

blades are worn, they must be replaced as a set of three to

prevent unbalanced operation with consequential dangerous

vibration and possible damage to the tool.

Note: The ridge along the blade should be on the blade

face on the opposite side to the clamping screws (11).

3. Tighten the clamping screws

(11), in the following manner.

Tighten the two outside

clamping screws snug tight,

then the next two screws,

then the middle screw.

Working in the same order,

fully tighten all five screws.

1

3

5

4

2

Order of tightening

clamping screws