12

2. Remove the damaged belt by pulling it sideways off the

top pulley and turning the bottom pulley by hand. Use a

soft brush to clean the pulleys and the surrounding area

Note. Wear eye protection when cleaning out the pulley area.

3. With the six continuous “v” profiles on the inside, place

the new belt over the bottom pulley. Half fit the other end

of the belt on the top pulley then roll the belt in place

whilst turning the pulley.

4. Check that the belt runs

evenly by manually turning

the belt.

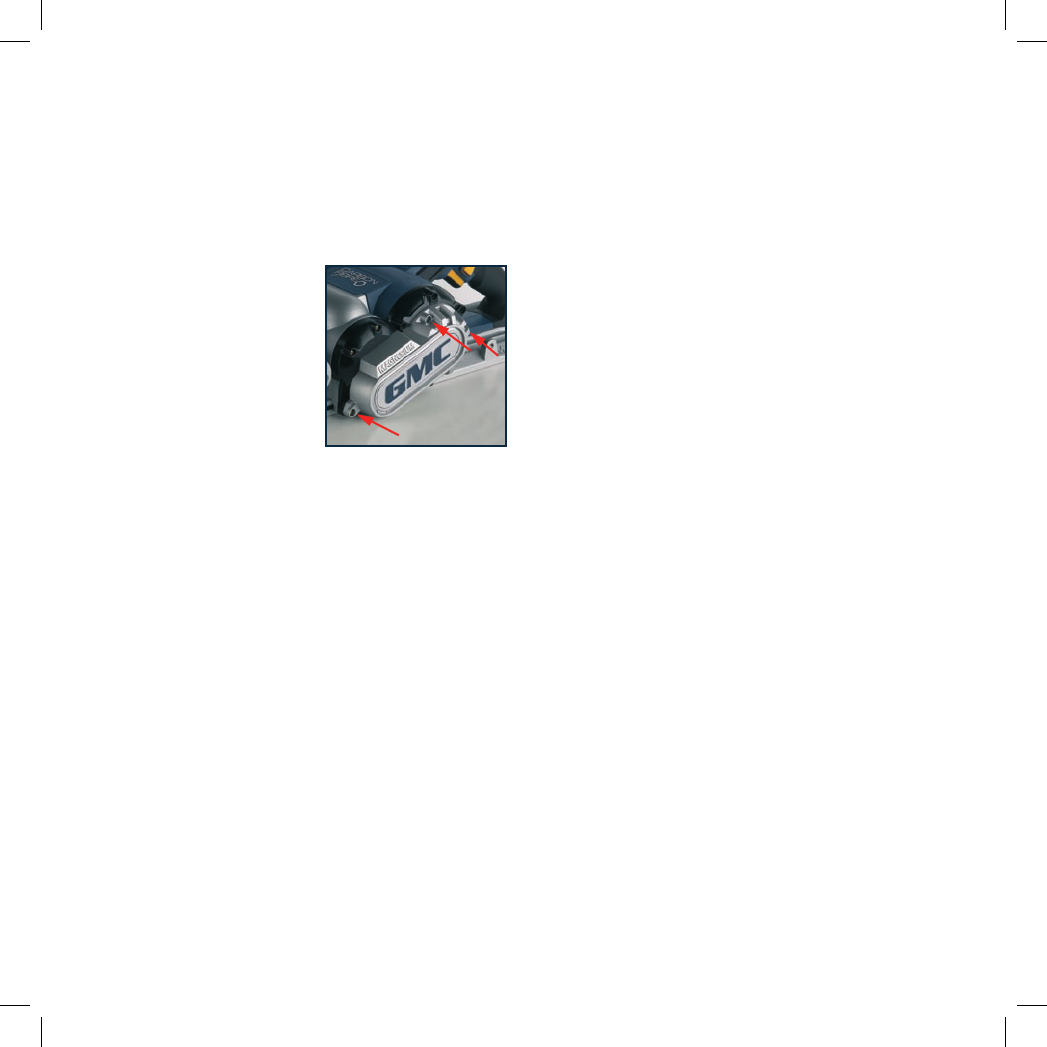

5. Replace the cover and the

three fixing screws ensuring

that the longer screw is

located in the hole at the

front of the cover.

6. Plug the machine back into the power outlet and switch

the tool on and run for a minute to make sure that the

motor and belt are operating correctly.

Maintenance

WARNING. Always ensure that the tool is switched off and

the plug is removed from the power point before making any

adjustments or maintenance procedures.

Regularly check that all the fixing screws are tight. They

may vibrate loose over time.

Cleaning

1. Keep the tool’s air vents unclogged and clean at all times.

2. Remove dust and dirt regularly. Cleaning is best done

with compressed air or a dry, soft to medium brush like a

paint brush.

CAUTION. Wear protective goggles when cleaning the tool.

3. Re-lubricate all moving parts at regular intervals.

4. Never use caustic agents to clean plastic parts.

CAUTION. Do not use cleaning agents to clean the plastic

parts of the tool. A mild detergent on a damp cloth is

recommended. Water must never come into contact with

the tool. Ensure the tool is thoroughly dry before using it.

Power cord maintenance

If the supply cord needs replacing, the task must be

carried out by the manufacturer, the manufacturer’s agent,

or a qualified electric service repairer in order to avoid a

safety hazard.