Overview

The saw is capable of ripping and cross cutting

hardwoods, softwoods and man made boards quickly,

accurately and safely.

If the tool becomes too hot, let it run under no load for

2–3 minutes to cool the motor.

The quality of the cut will improve as the number of blade

teeth increases.

The blade cuts on an upward stroke and may chip the

uppermost surface or edges of your work piece. When

cutting, ensure that your uppermost surface is a non-

visible surface when your work is finished.

By slackening the bevel adjustment knob (6), the body

and the blade of the saw can be tilted to any

angle up to

45° for making angle cuts. Please note that the maximum

depth of cut is reduced when cutting at an angle.

A fixed guard (13) encloses the upper part of the

blade. As the saw advances through the work piece, the

retracting blade guard (11) is pushed back by the edge

of the wood to expose only that part of the blade which

is needed. When the blade clears the work, the retracting

blade guard snaps back to completely enclose the blade.

Adjusting the cutting depth

Caution. Always ensure that the saw is switched off and

unplugged from the power supply before making any

adjustments.

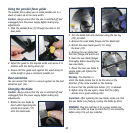

1. Ensure that the saw is facing away from you.

2. Loosen the depth locking lever (15).

3. Hold the base plate flat

against the edge of the

work piece and lift the

body of the saw until the

blade is at the right depth

- as shown on the indicator

(16).

4. Tighten the depth locking

lever (15).

Adjusting the depth locking lever

If the locking lever cannot be tightened enough to lock

the pivot point, it is time to adjust it.

1. Ensure the power is

disconnected from the

mains socket.

2. With a pair of circlip pliers

or a flat screwdriver blade,

carefully remove the circlip

from the pivot point nut.

3. Take off the lever and move

it back one section.

4. Replace lever and carefully re-fit the circlip.

5. Check the pivot point now locks tight when the lever is

pushed over to tighten.

Adjusting the bevel angle

Caution. Always ensure that the saw is switched off and

unplugged from the power supply before making any

adjustments.

1. Loosen the bevel

adjustment knob (6).

2. Tilt the body of the saw

until the required angle is

reached, using the bevel

scale (7) as a guide.

3. For accurate work it is

necessary to make a trial

cut, measure the work and

reset the angle until the correct setting is achieved.

4. Tighten the bevel adjustment knob (6) to secure the

base plate.

8